-

+86 15030157877

-

sales@galvanizedmetalmesh.com

sie . 09, 2024 01:30 Back to list

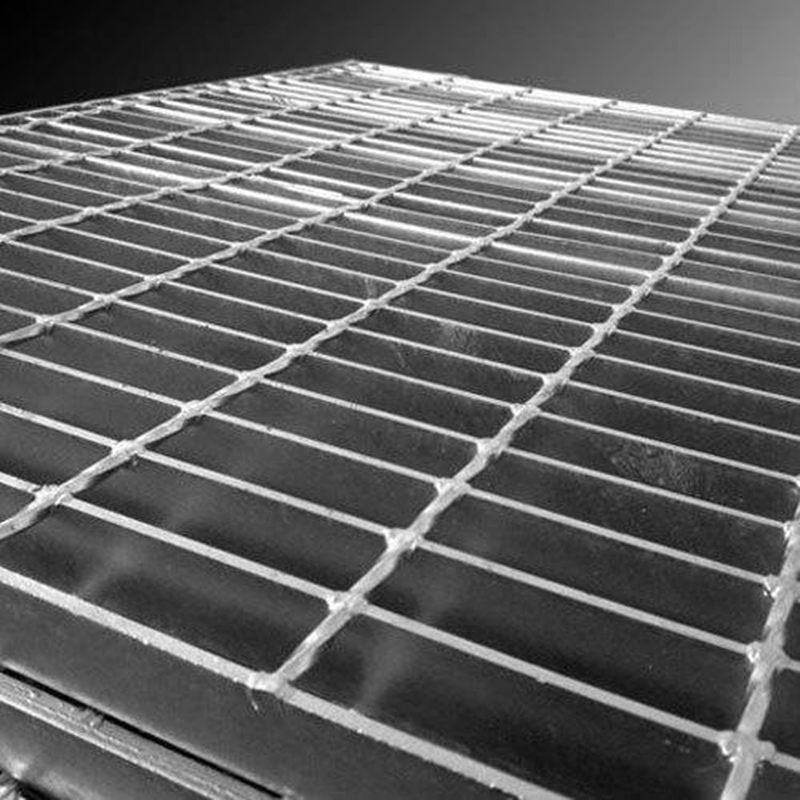

Stainless Steel Welded Wire Mesh Manufacturer for Durable and Reliable Industrial Applications

The Importance of Stainless Steel Welded Wire Mesh in Modern Applications

In recent years, the demand for stainless steel welded wire mesh has soared across various industries, thanks to its remarkable durability, strength, and resistance to corrosion. A stainless steel welded wire mesh factory plays a crucial role in producing these high-quality products that meet the diverse needs of consumers and businesses alike.

Stainless steel welded wire mesh is made by welding stainless steel wires at intersections, which creates a robust grid structure. The choice of stainless steel, known for its excellent mechanical properties and resistance to atmospheric corrosion, ensures that the finished product is not only strong but also long-lasting. This makes it suitable for a wide range of applications, from construction and agriculture to manufacturing and decorative projects.

One of the primary advantages of using stainless steel welded wire mesh is its versatility. It can be fabricated in various sizes, shapes, and wire thicknesses, allowing it to cater to specific requirements of different industries. In construction, for instance, it is commonly used for reinforcing concrete, providing additional strength and stability. The mesh also serves as a protective barrier, preventing unwanted access and enhancing security. In agricultural settings, it is employed for fencing to protect crops and livestock from predators while allowing for adequate airflow and sunlight.

In the manufacturing sector, stainless steel welded wire mesh is integral to the production of filters, sieves, and screens

. Its ability to withstand high temperatures and corrosive environments makes it an ideal choice for chemical and food processing applications. Additionally, its hygienic properties contribute to food safety, as it can be easily cleaned and sanitized.stainless steel welded wire mesh factory

The environmental benefits of stainless steel welded wire mesh are noteworthy as well. Stainless steel is a recyclable material, which means that products made from it can be repurposed at the end of their lifecycle, reducing waste and conserving natural resources. Furthermore, the durability of stainless steel reduces the need for frequent replacements, leading to less energy consumption and lower carbon emissions over time.

The production process at a stainless steel welded wire mesh factory is crucial in ensuring the quality of the final product. Utilizing advanced welding techniques and precision machinery, skilled workers meticulously craft each piece of wire mesh to meet stringent quality standards. The factories also often conduct rigorous tests to ensure that the welded wire mesh can withstand various environmental conditions, ensuring reliability in its applications.

In addition to industrial applications, stainless steel welded wire mesh has gained popularity in decorative features. Its aesthetic appeal, combined with its robustness, makes it an excellent choice for modern design elements in architecture and landscaping. From decorative railings and partitions to artistic displays, the possibilities are virtually limitless.

In conclusion, the significance of stainless steel welded wire mesh cannot be overstated. Its wide range of applications, coupled with its durability, strength, and resistance to corrosion, makes it an essential material across various industries. The role of stainless steel welded wire mesh factories is crucial in providing high-quality products that meet the growing demands of the global market. As industries continue to innovate and evolve, the importance of this versatile material will likely only increase, solidifying its place as a staple in modern construction and manufacturing solutions.

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025