-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 31, 2024 00:29 Back to list

Galvanized Welded Wire Mesh for Strong Steel Matting Applications

Understanding Galvanized Welded Wire Mesh A Versatile Solution for Steel Matting

Galvanized welded wire mesh is a highly versatile and durable material widely used in various applications, ranging from construction to agriculture. This article aims to explore the properties, manufacturing process, applications, and benefits of galvanized welded wire mesh, particularly in the context of steel matting.

What is Galvanized Welded Wire Mesh?

Galvanized welded wire mesh consists of metal wires that are welded together in a grid pattern and then coated with a layer of zinc through the galvanization process. This coating provides excellent corrosion resistance, making the mesh ideal for outdoor and industrial applications where exposure to moisture is a concern. The mesh can be customized in terms of wire diameter, mesh opening size, and sheet size to meet specific project requirements.

Manufacturing Process

The manufacturing of galvanized welded wire mesh begins with the selection of high-quality steel wires. These wires are first cleaned and then prepped for welding. The next step involves passing the wires through a welding machine, where they are fused together at the intersections to form a strong grid structure. After the welding process, the entire mesh is subjected to galvanization, usually through hot-dip galvanization or electro-galvanization.

- Hot-Dip Galvanization In this method, the welded mesh is immersed in molten zinc, creating a thick and robust protective layer. This is the most effective method for ensuring long-lasting corrosion resistance. - Electro-Galvanization This method imparts a thinner zinc coating through an electrochemical process. While it offers some protection against rust, it is generally less durable than hot-dip galvanization.

Applications

Galvanized welded wire mesh has a wide array of applications due to its strength, durability, and flexibility. Some of the most common applications include

1. Construction Often used as reinforcement in concrete and masonry structures, galvanized welded wire mesh provides additional strength to slabs, walls, and footings. It helps in controlling cracking and improves the overall structural integrity.

2. Fencing The mesh serves as an effective fencing solution for residential, agricultural, and industrial settings. It can deter intruders while still allowing visibility.

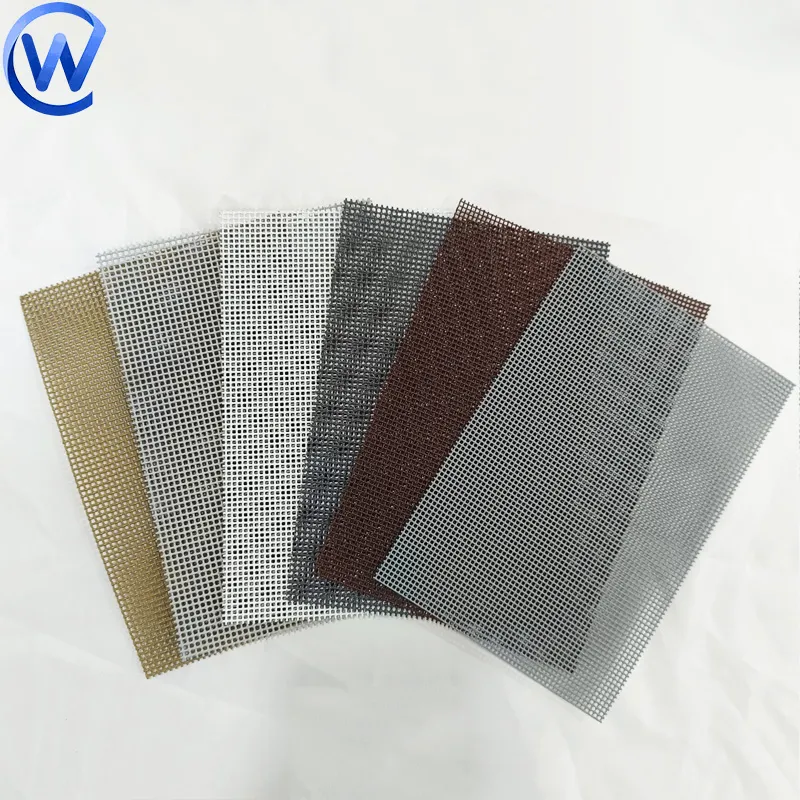

steel matting galvanized welded wire mesh

3. Animal Enclosures Farmers use galvanized welded wire mesh to create sturdy enclosures for livestock, poultry, and other animals. Its resistance to rust prolongs the life of animal housing structures.

4. Landscaping The mesh can serve as a strong framework for a variety of landscaping applications, including retaining walls, erosion control, and garden fencing.

5. Industrial Applications Manufacturing industries often employ galvanized wire mesh for product containment, storage bins, and machinery guards, given its ability to withstand heavy loads and environmental wear.

Benefits of Galvanized Welded Wire Mesh

1. Corrosion Resistance The zinc coating provides significant protection against rust, making it an ideal choice for outdoor applications.

2. Strength and Durability The fusion of wires adds structural integrity, allowing the mesh to handle heavy loads without bending or breaking.

3. Lightweight and Easy Installation Despite its strength, galvanized welded wire mesh is relatively lightweight and easy to handle, facilitating quick installation.

4. Cost-Effectiveness The longevity and durability of galvanized welded wire mesh translate to reduced maintenance and replacement costs over time.

5. Versatility Its wide range of applications across different industries makes it a go-to material for many engineering and construction projects.

Conclusion

Galvanized welded wire mesh is an invaluable material that combines strength, durability, and versatility, making it suitable for a wide range of applications, from construction to fencing and agriculture. Its superior corrosion resistance, ease of installation, and cost-effectiveness further enhance its appeal. As industries continue to evolve and innovate, galvanized welded wire mesh is poised to remain a fundamental material for various projects, showcasing its longstanding effectiveness in the realms of construction and beyond.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025