-

+86 15030157877

-

sales@galvanizedmetalmesh.com

lip . 30, 2024 00:12 Back to list

Supplier of High-Quality Perforated Metal Mesh Sheets for Diverse Applications and Industries

The Importance of Perforated Metal Mesh Sheets and Choosing the Right Supplier

Perforated metal mesh sheets have become integral components in various industries, thanks to their versatility and functional attributes. They consist of a flat sheet of metal that has been punched with holes to create a pattern, efficiently combining aesthetic appeal with practicality. These sheets are used in applications ranging from architectural elements to industrial functions, making them indispensable in modern manufacturing and construction.

Applications of Perforated Metal Mesh Sheets

The application spectrum of perforated metal sheets is vast. In architectural design, they often serve as cladding for buildings, providing a stylish finish while allowing natural light and air to permeate. This feature not only enhances the visual appeal of structures but also promotes energy efficiency by minimizing reliance on artificial lighting and ventilation systems.

In the industrial sector, perforated metal sheets play a critical role in filtration systems, providing a means to separate solids from liquids or gases. Their customizable hole patterns, sizes, and shapes allow industries such as food processing and pharmaceuticals to ensure stringent quality standards by filtering contaminants effectively.

Moreover, they are frequently utilized in the automotive market for parts such as grills, heat shields, and decorative accents. The lightweight yet sturdy nature of these sheets makes them ideal for reducing the overall weight of vehicles without sacrificing durability or performance.

Benefits of Perforated Metal Mesh Sheets

The benefits of using perforated metal mesh sheets extend beyond their functionality. They are a cost-effective solution due to their strength-to-weight ratio, which makes them lighter than solid metal sheets while retaining robustness. Additionally, their ability to be produced in various metals, including aluminum, steel, and brass, provides options for different environments and requirements.

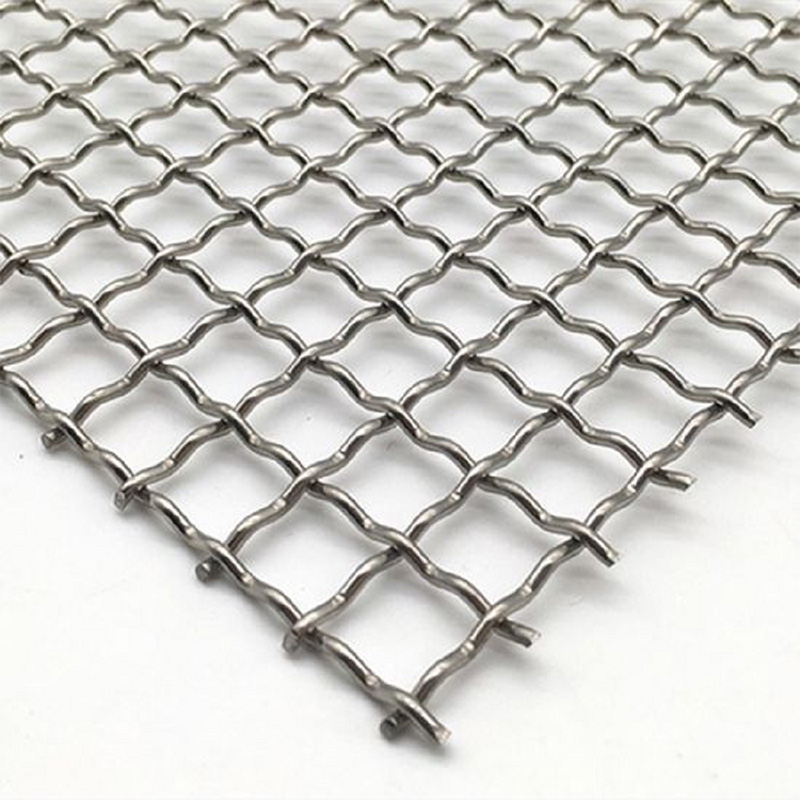

perforated metal mesh sheet supplier

Perforated sheets are also easy to fabricate, meaning they can be cut, bent, and welded to fit specific needs, further enhancing their versatility. They can be coated for added protection against corrosion, improving their longevity and reducing maintenance costs.

Choosing the Right Supplier

With the significant importance of perforated metal mesh sheets in industry, selecting the right supplier is paramount to ensuring quality and reliability. Factors such as the supplier's experience, production capabilities, and quality assurance processes should be meticulously evaluated.

A reputable supplier should offer a range of materials and customizable options to meet specific project requirements. They should also possess the capability to deliver timely and efficient service to prevent any disruptions in the supply chain. Customer reviews and testimonials can provide insights into the supplier's performance and reliability, aiding in the decision-making process.

Furthermore, it's essential to consider suppliers who prioritize sustainability. The metal industry has a considerable environmental impact, and choosing a supplier that implements eco-friendly practices can contribute to more sustainable operations.

Lastly, communication with the supplier is critical. A supplier who provides transparent information regarding lead times, pricing, and material specifications will foster a productive working relationship, leading to successful project outcomes.

Conclusion

In conclusion, perforated metal mesh sheets are vital in various sectors, offering a blend of beauty and functionality. As industries increasingly rely on them for diverse applications, finding the right supplier becomes a significant consideration. Evaluating suppliers based on experience, versatility, sustainability, and communication will pave the way for successful projects that utilize this innovative material. Quality perforated metal mesh sheets not only enhance performance but also contribute to the aesthetic value and efficiency of any construction or manufacturing process.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025