-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 19, 2024 19:16 Back to list

tomatoes wires spirals manufacturers

The Role of Wires and Spirals in Tomato Cultivation An Overview of Manufacturers

Tomato cultivation, a significant agricultural practice worldwide, involves various innovative techniques to enhance growth, productivity, and quality. Among these techniques, the use of wires and spirals has emerged as a crucial component for supporting plants and optimizing their growth conditions. This article delves into the significance of wires and spirals in tomato farming, exploring the manufacturing landscape of these essential tools.

Understanding Wires and Spirals in Tomato Cultivation

Tomatoes, being climbing plants, require proper support to thrive. Wires and spirals serve as vertical structures that help guide their growth upward, preventing them from sprawling on the ground. This method is not only beneficial for maximizing space in greenhouses and gardens but also enhances air circulation around the plants, reducing the risk of disease. Proper support also facilitates better sunlight exposure, which is critical for photosynthesis and fruit ripening.

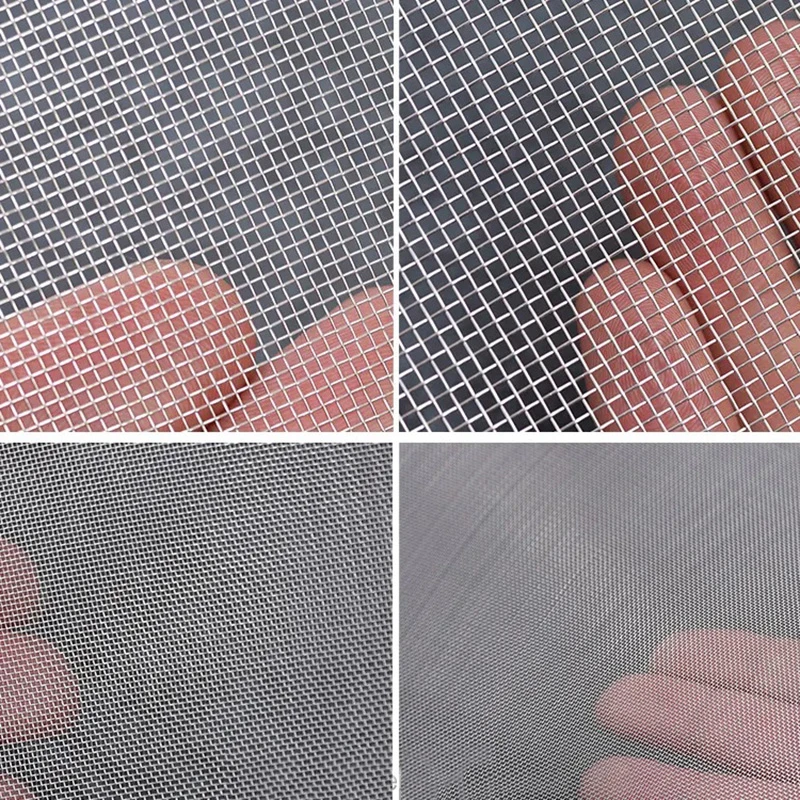

Wires, often made from durable materials such as stainless steel or galvanized iron, are strung between stakes or posts in a garden, allowing tomatoes to climb naturally. Spirals, on the other hand, are typically made of flexible, sturdy materials like plastic or wire, designed to hold the tomato plants in place as they grow. These structures provide stability, minimizing the risk of breakage during adverse weather conditions, such as storms or heavy winds.

Benefits of Using Wires and Spirals

1. Space Efficiency In commercial tomato farming, land use is critical. By utilizing vertical space through wires and spirals, farmers can grow more plants in a smaller area, thus increasing overall yield.

2. Disease Prevention Elevated plants are less susceptible to soil-borne diseases. By keeping the fruit off the ground, farmers can reduce the likelihood of rot and pest infestations.

3. Ease of Harvesting When tomatoes are trained to grow along wires or spirals, harvesting becomes more straightforward. This efficiency is especially valuable in large-scale operations where labor costs are a concern.

tomatoes wires spirals manufacturers

4. Improved Quality of Produce Well-supported plants tend to produce higher quality fruits. They are less likely to suffer from bruising and can achieve better size and flavor attributes, leading to higher market prices.

The Market for Wires and Spirals Manufacturers and Innovations

The demand for wires and spirals in tomato cultivation has prompted an array of manufacturers to enter the market. These companies vary from local, small-scale producers to large global corporations. Many manufacturers focus on developing innovative products tailored to the specific needs of tomato growers.

Local Manufacturers Smaller manufacturers often focus on organic materials and sustainable practices. They may offer biodegradable options for wire supports or spirals, catering to eco-conscious farmers. These products not only support plant growth but also contribute positively to soil health when they decompose.

Global Corporations Larger companies tend to invest in research and development to create more durable and efficient products. Innovations such as adjustable spirals or multi-tiered wire systems allow farmers to customize their setups based on the variety of tomatoes being grown or specific climatic conditions.

Technological Advancements Recent trends see manufacturers integrating technology into their products. Smart supports, equipped with sensors to monitor plant health and growth conditions, are emerging in the market. This integration could revolutionize how tomato farmers approach cultivation, allowing for data-driven decision-making.

Conclusion

The use of wires and spirals in tomato cultivation not only enhances growth but also maximizes yield and quality, making them indispensable tools in modern agriculture. As the demand for tomatoes continues to rise globally, manufacturers of these supportive structures are stepping up to meet the needs of farmers. With ongoing innovations and a focus on sustainability, the future of wire and spiral manufacturing looks promising, ultimately benefiting both producers and consumers in the ever-evolving agricultural landscape. By embracing these advancements, tomato growers can ensure a more productive, sustainable, and profitable farming future.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025