-

+86 15030157877

-

sales@galvanizedmetalmesh.com

paź . 18, 2024 20:44 Back to list

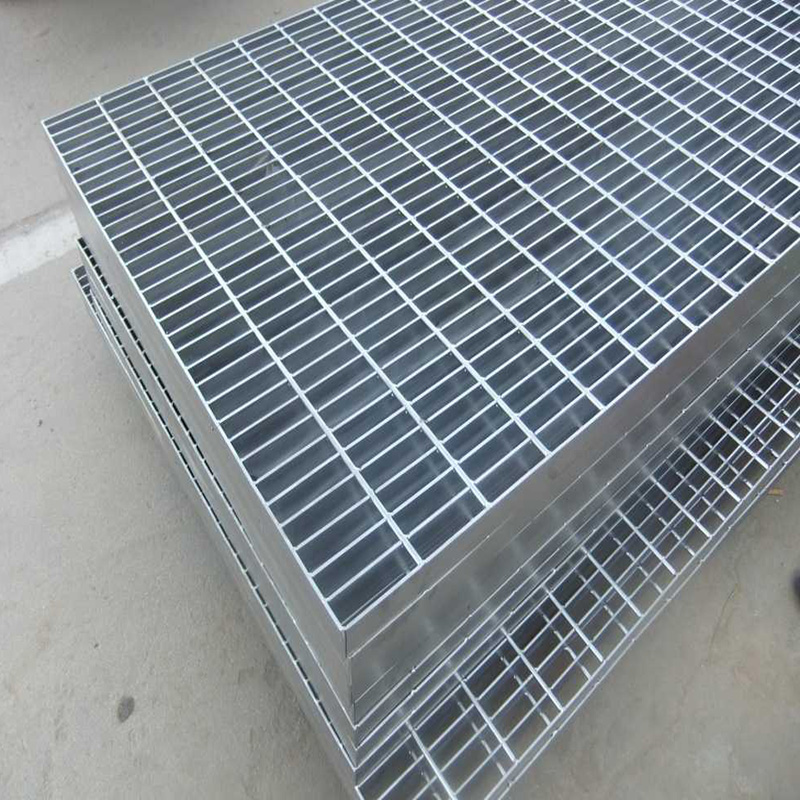

Wire mesh sheet manufacturing process and quality standards for industrial applications

Understanding Wire Mesh Sheet Factories A Comprehensive Overview

Wire mesh sheets are an integral part of various industries, serving a multitude of purposes ranging from construction and agriculture to mining and food processing. At the heart of their production lies the wire mesh sheet factory, an establishment equipped with advanced technologies and skilled labor dedicated to creating high-quality wire mesh products. In this article, we will delve into the workings of wire mesh sheet factories, exploring their processes, applications, and significance in modern industries.

The Manufacturing Process

The production of wire mesh sheets begins with excellent raw materials, typically high-quality steel wire. The manufacturing process generally includes several key stages wire drawing, weaving, and finishing.

1. Wire Drawing This initial stage involves pulling raw steel wire through a series of dies to reduce its diameter and improve its strength. The wire is precisely drawn to meet specific diameter requirements based on the intended application of the final mesh product.

2. Weaving Once the wire is ready, it undergoes the weaving process, where machines interlace the wires to create a robust mesh. The weaving technique employed can vary, including welded, woven, or woven-wire methods, depending on the desired characteristics of the final product. Automated looms are typically utilized to ensure precision and consistency.

3. Finishing After weaving, the wire mesh sheets require finishing processes, which may include cutting to size, galvanizing for rust resistance, and coating for added durability. These finishing touches enhance the mesh's performance and longevity, making it suitable for various environmental conditions.

Applications of Wire Mesh Sheets

Wire mesh sheets are incredibly versatile and have found applications across numerous sectors

. Some common uses include- Construction In the construction industry, wire mesh is frequently used for reinforcing concrete, providing structural integrity and supporting heavy loads. It is also used as fencing material, ensuring security around construction sites.

wire mesh sheet factory

- Agriculture Farmers utilize wire mesh sheets for various purposes, including fencing livestock, creating cages for poultry, and supporting plant growth through trellises. The durability and strength of wire mesh make it an ideal choice for agricultural applications.

- Mining and Quarrying In the mining sector, wire mesh is essential for separating materials and ensuring the safety of operations. It is used in screens, sieves, and protective barriers, making mining processes more efficient.

- Food Processing In the food industry, wire mesh sheets are used for filtration and sieving, ensuring that products are free from contaminants. Stainless steel wire mesh, in particular, is favored for its corrosion resistance and hygienic properties.

The Importance of Quality Control

In a wire mesh sheet factory, quality control is paramount. Each stage of production is monitored to ensure that the end product meets industry standards and customer expectations. Factors such as mesh size, wire thickness, and resistance to corrosion are critical in determining the quality of the wire mesh. Rigorous testing procedures, including tensile strength analysis and corrosion resistance assessments, are implemented to guarantee that the final products can withstand their intended applications.

Innovation and Sustainability

As industries evolve, so do the technologies and methods employed within wire mesh sheet factories. Innovations in production techniques, such as automation and computer-aided design, have significantly improved efficiency and precision. Additionally, many factories are now adopting sustainable practices, including recycling scrap materials and using eco-friendly coatings, to minimize their environmental impact.

Conclusion

Wire mesh sheet factories play a crucial role in producing versatile products that serve a multitude of industries. From construction and agriculture to mining and food processing, the applications of wire mesh sheets are vast and varied. By understanding the manufacturing processes, applications, and the importance of quality control, we can appreciate the significant impact of wire mesh sheets in our daily lives. As technology continues to advance, the future of wire mesh production looks promising, with innovations paving the way for even more efficient and sustainable practices.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025