-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 16, 2024 17:55 Back to list

Understanding Crimped Woven Mesh and Its Applications in Various Industries

Crimped Woven Mesh An Overview of Its Applications and Benefits

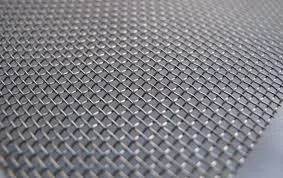

Crimped woven mesh is a versatile and essential material used in various industries due to its unique characteristics and functional properties. The process of creating crimped woven mesh involves interlacing strands of wire in a specific pattern and applying a crimping technique to enhance the structural integrity and functional performance of the mesh. This article delves into the features, applications, and benefits of crimped woven mesh, highlighting its significance in modern manufacturing and construction.

One of the defining features of crimped woven mesh is the crimping process itself, which involves bending or shaping the wire at regular intervals before weaving. This not only increases the rigidity of the mesh but also improves its tensile strength, ensuring that it can withstand considerable stress and strain. The crimped design creates a three-dimensional structure, which enhances the air and liquid flow properties of the mesh, making it particularly beneficial in applications where filtration and separation are critical.

Crimped woven mesh is widely used in various sectors, including mining, agriculture, construction, and industrial filtration. In the mining industry, it serves as a crucial tool for sorting and separating ores and minerals. The mesh allows for the efficient collection of materials while preventing fine particles from escaping, thus optimizing resource extraction. In agriculture, crimped woven mesh is often utilized in fencing to protect crops and livestock from predators. Its durability ensures that it can withstand harsh environmental conditions, making it a reliable choice for farmers.

crimped woven mesh

In the construction sector, crimped woven mesh is frequently employed as a reinforcement material in concrete. The mesh enhances the tensile properties of concrete structures, providing increased resistance to cracking and deformation. This is particularly important in large-scale construction projects, where structural integrity is paramount. Additionally, crimped woven mesh finds application in architectural designs, offering both aesthetic appeal and functional benefits, such as allowing for effective ventilation and natural lighting.

Another significant application of crimped woven mesh is in industrial filtration systems. The mesh serves as a reliable filtering medium for liquids and gases, trapping contaminants and ensuring that only clean, high-quality materials pass through. Its ability to provide precise filtration makes it an essential component in industries such as food and beverage processing, water treatment, and chemical production. The variation in crimping patterns and wire gauges allows for customization according to specific filtration needs.

Moreover, crimped woven mesh is known for its longevity and low maintenance requirements. The materials used in its production, such as stainless steel, aluminum, and carbon steel, possess excellent corrosion resistance, ensuring that the mesh remains functional even in hostile environments. This characteristic contributes to its cost-effectiveness, as it reduces the need for frequent replacements and repairs.

In summary, crimped woven mesh is a multifaceted material that offers significant advantages across various industries. Its unique crimping design enhances structural strength, while its diverse applications in mining, agriculture, construction, and filtration highlight its versatility. As industries continue to evolve, the demand for durable and efficient materials like crimped woven mesh is expected to grow, reinforcing its essential role in both traditional and modern applications.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025