-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ago . 09, 2024 06:00 Back to list

Exploring the Production Process of Steel Angle Bars in Global Manufacturing Facilities

The Importance of Steel Angle Bar Factories in Modern Industry

Steel angle bars are vital components in various construction and manufacturing processes. Their L-shaped cross-section provides a unique combination of strength and versatility, making them suitable for a wide range of applications including framing, supports, and structural components. This article explores the significance of steel angle bar factories in today's industrial landscape, emphasizing their role in providing essential materials that facilitate progress and innovation.

Steel angle bar factories are specialized facilities that manufacture these essential materials using advanced technologies and techniques. The production process typically involves the melting of raw steel in furnaces, followed by continuous casting. Once the steel is cast, it undergoes hot or cold rolling to achieve the desired dimensions and properties. These factories have the capability to produce a variety of sizes, grades, and finishes, catering to the diverse requirements of industries such as construction, shipbuilding, automotive, and manufacturing.

One of the primary advantages of steel angle bars is their inherent strength-to-weight ratio. This characteristic enables designers and engineers to create lighter structures without compromising stability. For instance, in the construction of skyscrapers or large bridges, the efficient use of steel angle bars reduces the overall weight of the framework, allowing for greater design flexibility and cost savings. Moreover, the resilience and durability of steel angle bars ensure that they can withstand harsh environmental conditions, making them an ideal choice for outdoor applications.

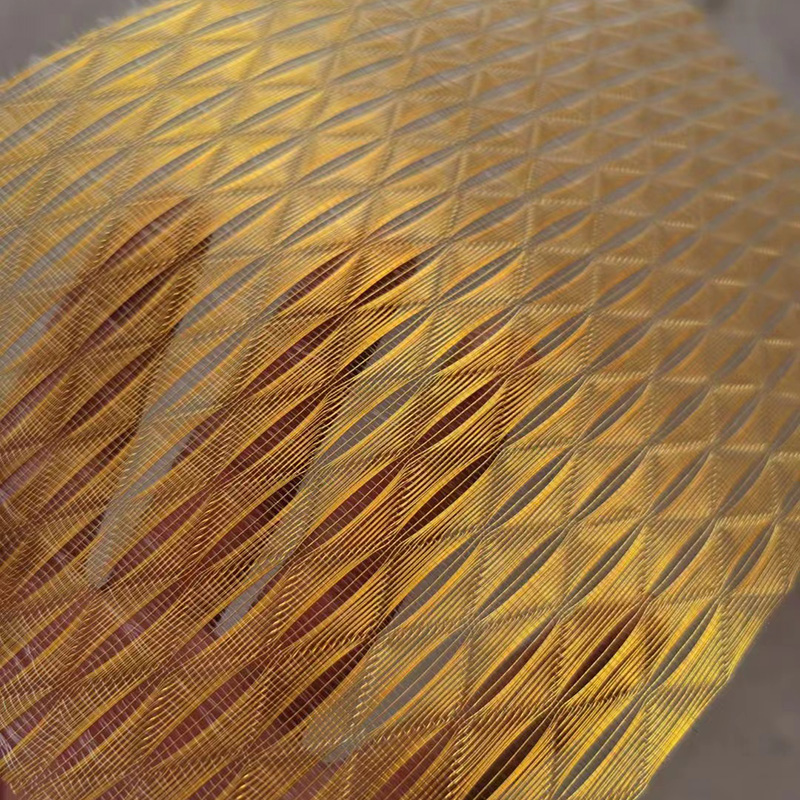

steel angle bar factories

Sustainability is a growing concern in the industrial sector, and steel angle bar factories are increasingly adopting eco-friendly practices. Many manufacturers are investing in recycling programs to ensure that scrap steel is reprocessed and reused in production. This not only conserves natural resources but also reduces waste and energy consumption associated with the extraction and processing of new raw materials. As a result, the steel industry is making strides toward a more sustainable future, with steel angle bars playing a crucial role in this transition.

Additionally, steel angle bar factories are pivotal in driving technological advancements. They are equipped with cutting-edge machinery and automation systems that enhance production efficiency and quality control. For example, the integration of computer numerical control (CNC) technology allows for precise cutting, drilling, and shaping of steel angle bars, thereby reducing material waste and increasing accuracy. This technological innovation not only improves productivity but also ensures that products meet stringent industry standards.

Moreover, the global demand for steel angle bars has been on the rise, driven by increased construction activities and infrastructural development in emerging economies. This surge in demand presents significant opportunities for steel angle bar factories to expand their operations and explore new markets. By adapting to changing consumer preferences and investing in research and development, these manufacturers can stay competitive and continue to meet the evolving needs of their clients.

In conclusion, steel angle bar factories are integral to the functionality and advancement of numerous industries. They provide essential materials that support construction, enhance sustainability, foster technological innovation, and drive economic growth. As the world continues to urbanize and industrialize, the role of these factories will only become more pronounced, underscoring the need for ongoing investment in infrastructure and manufacturing capabilities. Embracing these opportunities will not only benefit the factories themselves but also contribute to a stronger, more resilient industrial ecosystem worldwide.

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025