-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 29, 2025 20:00 Back to list

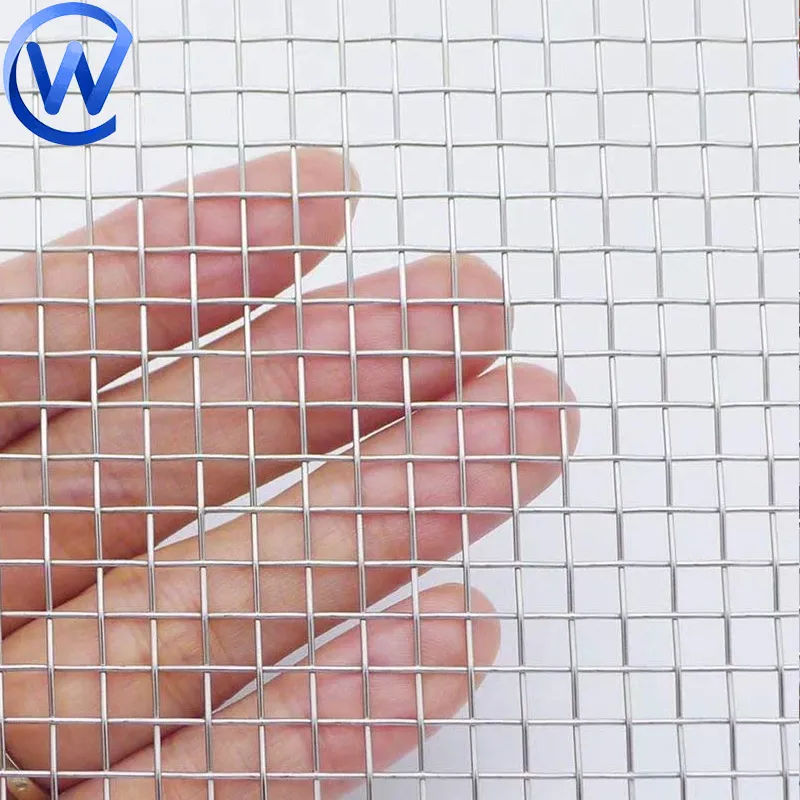

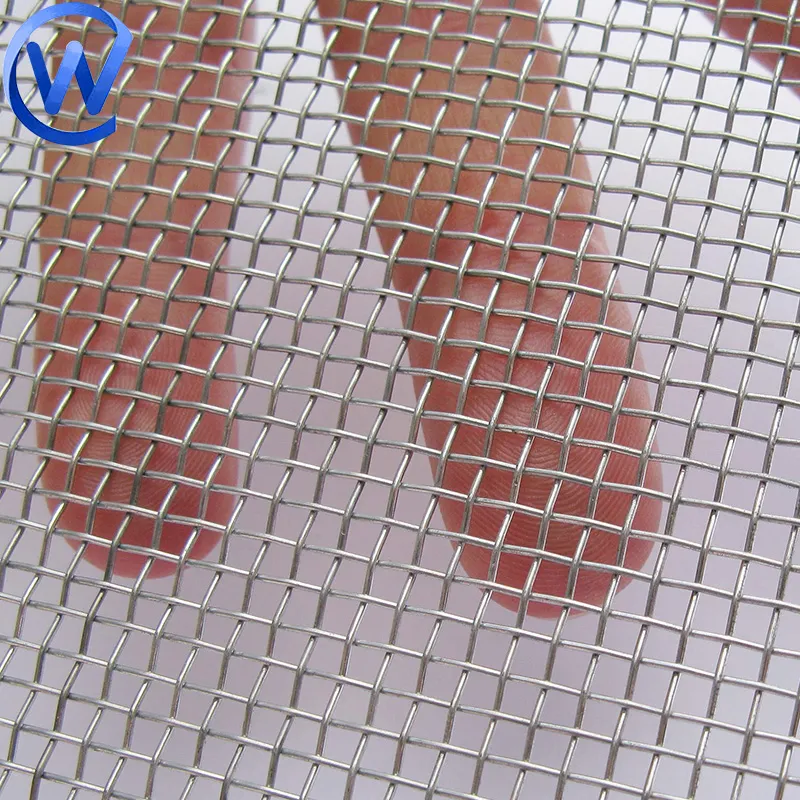

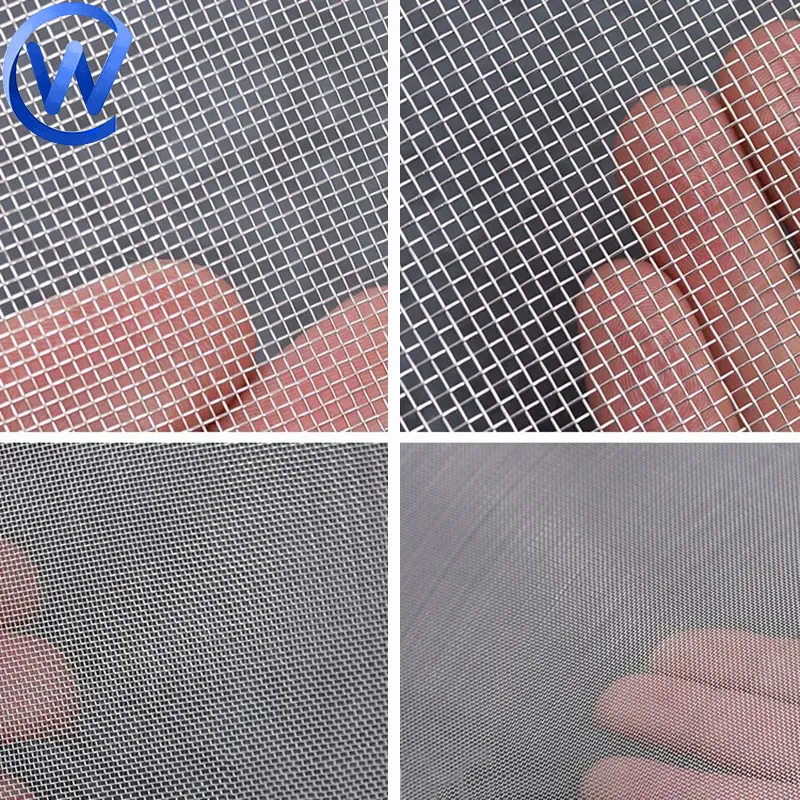

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

1. Industry Trends: Square Wire Mesh Market Insights 2024

As per the 2024 Global Mesh Market Report, the global demand for square wire mesh is expected to grow by 6.8% CAGR during 2024-2029, driven by rapid expansion in oil & gas, filtration, and construction sectors (Marketresearch.com). Customization, technological upgrades in weaving and coating, and compliance to ISO/ANSI standards have been pivotal in new projects and tenders.

- Asia-Pacific remains the biggest market, with leading square wire mesh manufacturers and exporters handling 62% of global orders.

- Intelligent monitoring (online mesh integrity, AI-based flaw detection) enters high-value custom projects.

- Material innovation: SUS316L, duplex stainless steels, and advanced galvanization increase mesh lifespan and reduce maintenance by up to 40% in high-corrosion scenarios (API/ISO tests, 2023).

2. Square Wire Mesh: Technology, Material & Specification Table

Premium Materials

Most high quality square wire mesh products utilize SS304/316L, pre-galvanized steel, and low carbon steel. Advanced alloys (>21%Cr, 2.5%Mo) target extreme chemical environments, passing ISO 9227 salt spray and ASTM B117 tests.

Precision Manufacturing

Modern weaving and CNC forming ensure uniform aperture (tolerance <8%), critical for food, medical, and high-pressure filtration (ISO 9044 Standard).

Coating & Longevity

Galvanization & PVC coatings provide up to 20 years corrosion-resistance (tested per ISO 9227, QUV-accelerated aging), vital for oil & gas and marine use.

| Parameter | Stainless Steel (304/316L) | Galvanized Steel | Low Carbon Steel | PVC Coated |

|---|---|---|---|---|

| Wire Diameter | 0.25–3.0 mm | 0.5–2.5 mm | 0.4–3.5 mm | 0.7–3.0 mm |

| Mesh Opening | 2–50 mm | 5–100 mm | 8–100 mm | 4–50 mm |

| Roll Width | 0.5–2 m | 0.9–2.4 m | 0.9–2.6 m | 0.8–2.2 m |

| Roll Length | 10–30 m | 10–30 m | 10–30 m | 10–25 m |

| Tensile Strength | 620–820 MPa | 350–450 MPa | 295–415 MPa | 350–750 MPa |

| Corrosion Resistance | Excellent | Good | Fair | Excellent |

| ISO Standard Compliance | ISO 9044 / ASTM E2016 | ISO 9044 | ISO 9044 | ISO 9044, ISO 9227 |

3. Square Wire Mesh Manufacturing Process Explained

4. Top Square Wire Mesh Manufacturers & Suppliers (2024 Comparison)

- Production Traceability, Certifications, and Batch Testing Reports

- Customization Abilities (Non-standard mesh sizes, alloys, coatings)

- After-sale technical support, global logistics, and service experience

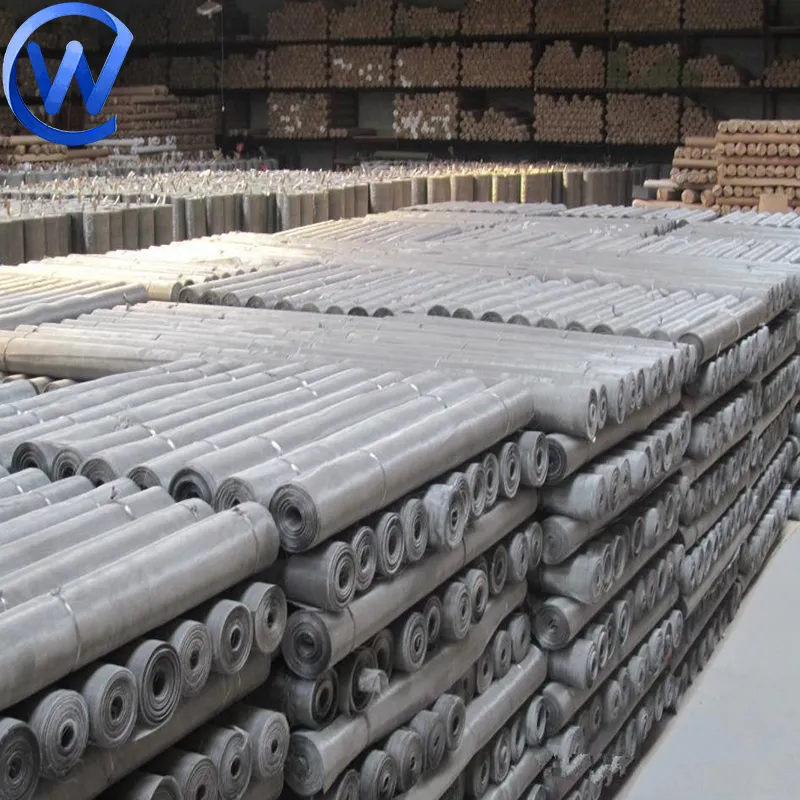

- Location: China

- Output: 8000+ tons/year

- Standards: ISO 9001:2015, SGS, CE

- Main Markets: Petrochemical, Filtration, Construction

- Notable: Vertically integrated square wire mesh factory with AI quality control.

- Location: USA

- Output: 3200+ tons/year

- Standards: ASTM, ISO 9001

- Main Markets: Architectural, Security, Industrial OEM

- Notable: Bespoke custom square wire mesh design, specialty alloys.

- Location: Switzerland/Germany

- Output: 2500+ tons/year

- Standards: ISO 14001, ISO 9001

- Main Markets: Pharma, Food, Water Treatment

- Notable: Ultrasonic cleaning, complex mesh geometries.

5. Custom Square Wire Mesh Solutions: Options & Parameters

Industrial buyers increasingly seek custom square wire mesh for non-standard apertures, unique alloys, or surface treatments that match demanding projects (seawater desalination, oil refineries, cleanrooms, etc.). Customization is defined by:

- Mesh Opening (Aperture): 0.5mm to 150mm, with ±5–8% tolerance

- Wire Diameter: 0.2mm (ultra-fine) to 4.0mm (heavy-duty reinforcing mesh)

- Material Choice: 304, 316L, galvanized, duplex, custom alloys (Monel, Inconel)

- Surface Finish: Bright annealed, electro-polished, powder coating, PVC, hot-dip galvanizing

- Roll/Sheet Size: Custom width (up to 2.8m), length (up to 50m)

- Testing: ISO/ANSI/ASTM test certificates upon request

- Min. Order: 10 m² (custom production), wholesale square wire mesh discounts available ≥500 m²

- Lead time: 7–18 business days for standard; 15–35 days for complex custom mesh

- ISO/SGS Test reports, RoHS/REACH certificates available

- Global door-to-door delivery (by sea/air/express)

| Mesh Size (mm) | Wire Dia. (mm) | Material | Finish | ISO Grade | Annual Orders (%) |

|---|---|---|---|---|---|

| 25 x 25 | 1.0 | 304 Stainless | Electropolished | ISO 9044 | 24% |

| 50 x 50 | 2.0 | Galvanized | Hot-dip, Blue passivated | ISO 9044 | 32% |

| 10 x 10 | 0.7 | 304/316L | Annealed, Clean | ISO 9044 | 16% |

| 20 x 20 | 1.2 | PVC Steel | PVC Black | ISO 9227 | 12% |

| 5 x 5 | 0.6 | 316L | Mirror Polish | ISO 9044/ASTM | 6% |

6. Real-World Applications: Square Wire Mesh Cases & Advantages

Oil & Gas Refinery Filtration

Saudi Aramco’s 2023 upgrade leveraged high quality square wire mesh (316L, 20x20mm, hot-dip galvanized) in separator tanks, reducing filter replacements by 41% (API RP 939, in-house reports). The mesh exhibited over 4,500 hours corrosion endurance in brine (per ISO 9227).

Pulp & Paper Industry Dewatering

International Paper installed custom-woven square wire mesh for dewatering processes—stainless mesh improved throughput by 13%, while reducing cleaning downtimes (ISO 12625-17 paper industry mesh standards).

Water Treatment (WWTP)

Large-scale municipal WWTP in Germany reported an increase in sediment retention (91.4% average, certified by DWA German Water Assoc. testing) from using annealed, high-tension square wire mesh.

Architectural Applications

New York’s Hudson Yards employed decorative square wire mesh claddings (304 mirror finish, mesh: 12x12mm) for facades, delivering both protection and ultra-modern aesthetics.

7. Square Wire Mesh: FAQ & Technical FAQ

8. Delivery, Warranty, Customer Support

- Delivery Time: Standard stock mesh shipped in 4-8 days. Custom/large volumes: 2–6 weeks.

- Warranty: 12–24 months for anti-corrosion & performance (terms per ISO or client contract).

- Customer Support: Pre-sales technical consulting, post-sales support, installation guidance, remote factory video inspection and urgent shipment handling.

- Worldwide Logistic Partners: DHL, FedEx, Maersk. Tracking code for every delivery.

- Certifications: CE, SGS, ISO9001, REACH, FDA grade (for food/medical).

- Industry users: PetroChina, Aramco, Samsung Engineering, Veolia, DOW Chemical (reference cases available).

Conclusion & References

The evolution of square wire mesh technology—supported by advances in materials, process automation, and stringent ISO/ASTM standards—continues to bring new value and assurance in filtration, structural, and specialty OEM applications. By leveraging certified suppliers, customizing solutions, and referencing real-life application data, procurement and technical teams secure optimum mesh performance across all industries.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025