-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 11, 2025 17:45 Back to list

Perforated Metal Mesh — Custom, Durable, Factory-Direct

Perforated Metal Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal mesh and mesh products. This article explores how HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Perforated Metal Mesh Overview

- Benefits & Use Cases of Perforated Metal Mesh in Manufacturing of metal mesh and mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Perforated Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Perforated Metal Mesh Overview

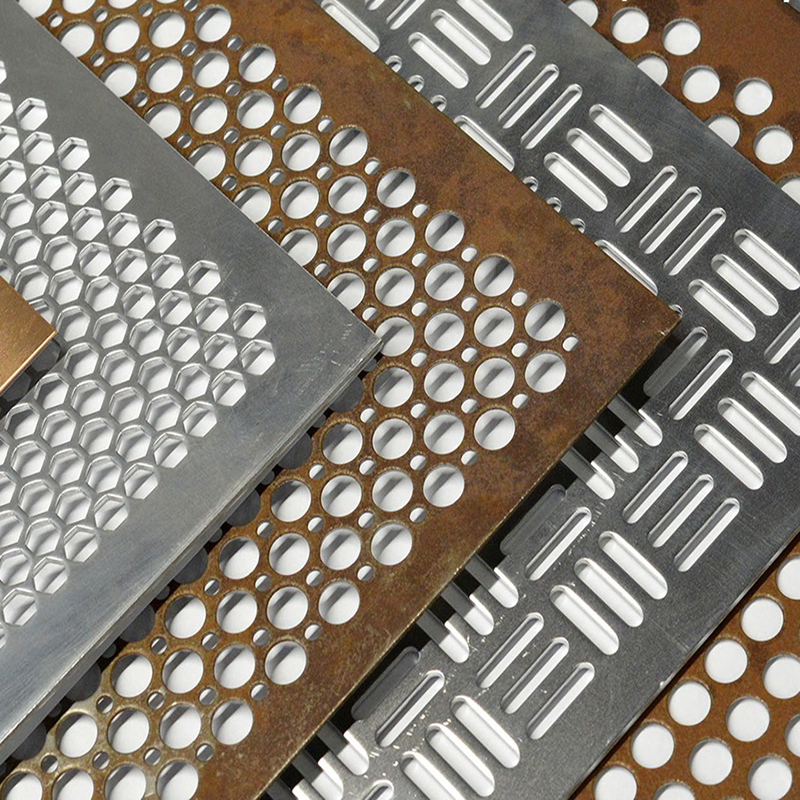

Perforated metal mesh is a precision-punched sheet that delivers a controlled balance of open area, strength, airflow, and aesthetics. In fabricated metal products and the broader manufacturing of metal mesh and mesh products, it is the go-to material for screening, ventilation, acoustic control, safety guards, filtration, and architectural facades. Typical materials include low-carbon steel, galvanized steel, aluminum, and metal stainless steel perforated metal mesh in grades 304/316 for superior corrosion resistance. Standard hole types include round, square, slotted, and decorative patterns with staggered or straight pitch. HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supplies both standard perforated metal mesh sheet and custom perforated metal mesh sheet, matching precise aperture, thickness, and open-area requirements.

Technical ranges commonly supported include thicknesses from 0.3–6.0 mm, hole diameters from 0.5–50 mm, open areas from 5–60%, and coil or sheet formats up to 1,500–2,000 mm width depending on material. Finishes may include hot-dip galvanizing, passivation, powder coating, or anodizing for aluminum. As experienced perforated metal mesh manufacturers and perforated metal mesh exporters, HEBEI WEICHUN provides tight tolerances, flatness control, deburring, and edge treatments to simplify downstream fabrication such as bending, rolling, welding, and assembly—reducing scrap and rework on customer lines.

Benefits & Use Cases of Perforated Metal Mesh in Manufacturing of metal mesh and mesh products

In industrial manufacturing, perforated metal mesh drives performance across multiple applications: filtration screens for powders and pellets; HVAC intake/exhaust grilles; acoustic panels for machinery noise reduction; machine guarding and safety enclosures; drying trays; grain and seed cleaning; battery and electronics ventilation; and architectural sunscreens and facades. The material’s high strength-to-weight ratio and predictable airflow/pressure-drop characteristics make it a robust, repeatable choice for OEMs and system integrators. For branding and design-led projects, custom perforated metal mesh enables unique hole patterns and open-area designs that align performance with aesthetics.

HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. delivers competitive advantages: consistent aperture accuracy, clean edges to protect operators and components, stable flatness for high-speed assembly, and rapid turnaround for wholesale perforated metal mesh and wholesale perforated metal mesh sheet programs. As a responsive perforated metal mesh supplier and perforated metal mesh factory, we support project-engineered kits, nested cutting, and surface finishing under one roof. Our engineering team helps specify the optimal pitch/open-area for target airflow, acoustic attenuation, or screening efficiency—minimizing trial cycles and accelerating time to market for B2B decision makers.

Cost, Maintenance & User Experience

Total cost of ownership for perforated metal mesh hinges on material selection, open area, and finishing. Stainless options offer long service life in corrosive or hygienic environments, while galvanized steel or aluminum can optimize cost and weight. Because perforated sheets are inherently rigid and abrasion-resistant, they withstand frequent cleaning, vibration, and impact better than many alternatives, extending maintenance intervals. Customers report faster line changeovers when switching to well-deburred, flat sheets—reducing downtime and improving ROI. In many air-handling and acoustic applications, tuning the open area can reduce fan energy or improve noise reduction, delivering measurable savings over the product lifecycle.

B2B clients in the fabricated metal products sector cite reliable supply, repeatable tolerances, and simplified fabrication as key benefits of partnering with HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. Our wholesale programs stabilize pricing and inventory, while custom perforated metal mesh and pre-formed components reduce in-house processing time. Typical lead times are aligned with OEM production windows, and our packaging prevents edge damage and surface scuffing. The result is a smoother user experience—from RFQ to first article to scaled delivery—backed by responsive technical support and quality documentation upon request.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping material choices in manufacturing. Perforated metal mesh supports circularity because steel, stainless steel, and aluminum are highly recyclable with established global streams. Specifying durable mesh with the right coating can extend service life, reduce replacements, and minimize waste. Many buyers now require compliance with RoHS/REACH and low-VOC finishing; powder coating and passivation are proven pathways. In building and industrial markets, trends include lightweighting, improved acoustic comfort, and energy efficiency—areas where tuned open-area designs and high-precision perforation deliver quantifiable benefits.

HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. positions itself as a forward-thinking, eco-conscious partner by prioritizing responsible sourcing, process optimization to reduce scrap, and options for recyclable packaging. As experienced perforated metal mesh exporters, we understand regional standards and documentation needs, supporting cross-border compliance and on-time delivery. Whether you require stainless solutions for long life, aluminum for reduced embodied weight, or coated steel for cost-performance balance, our team helps align specification with ESG goals without compromising function, cost, or lead time.

Conclusion on Perforated Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

For manufacturers seeking dependable performance and supply stability, perforated metal mesh delivers strength, airflow control, and durability across filtration, ventilation, safety, and architectural uses. HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. combines material expertise, precision punching, and flexible finishing to supply standard perforated metal mesh sheet and fully custom perforated metal mesh at scale. As a trusted manufacturer, supplier, and exporter, we help B2B teams reduce total cost and accelerate production. Contact us: email: sales@galvanizedmetalmesh.com – Visit our website: https://www.galvanizedmeshproducts.com

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NewsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NewsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NewsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NewsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NewsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NewsNov.11,2025