-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 11, 2025 19:05 Back to list

Perforated Metal Mesh – Custom, Stainless, Wholesale Pricing

Perforated Metal Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal mesh and mesh products. This article explores how HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Perforated Metal Mesh Overview

- Benefits & Use Cases of Perforated Metal Mesh in Manufacturing of metal mesh and mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Perforated Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Perforated Metal Mesh Overview

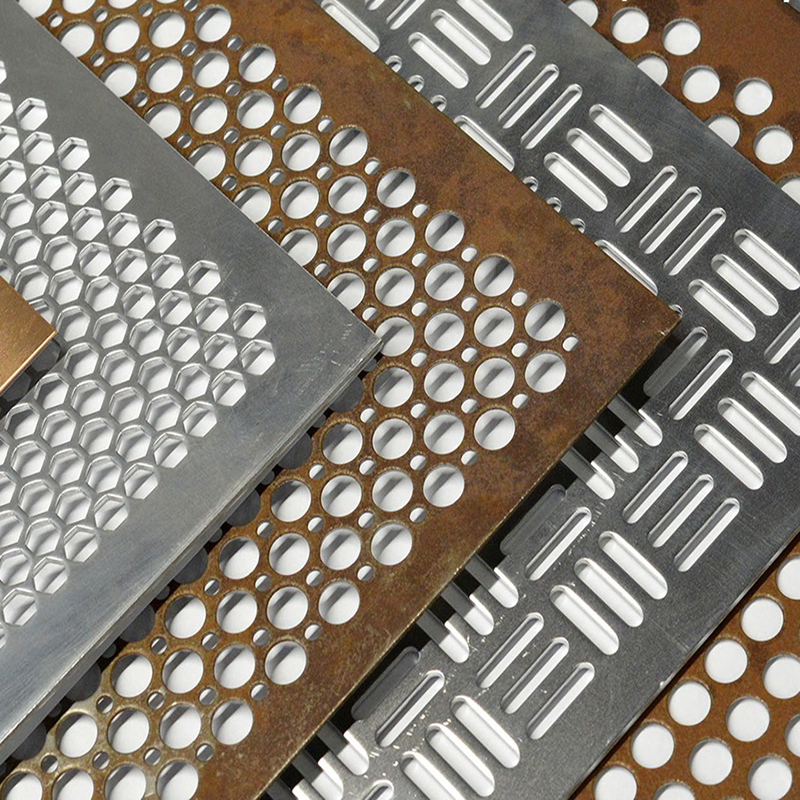

Perforated metal mesh is a precision-punched metal sheet that combines strength, open area, and tailored aesthetics. In fabricated metal products and the manufacturing of metal mesh and mesh products, it is widely specified for airflow, screening, acoustic control, safety guarding, and architectural cladding. Typical materials include carbon steel, aluminum, and metal stainless steel perforated metal mesh such as SS304/SS316. HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supplies standard perforated metal mesh sheet and custom perforated metal mesh options to meet tight tolerances and project-critical performance needs.

- Technical ranges: thickness 0.3–8.0 mm; hole types round, square, slotted/oblong, hex, and decorative; hole diameters 0.5–50 mm; open area 8–60%; staggered 60° or 45° patterns. Common sheet sizes: 1000×2000, 1250×2500, 1500×3000 mm; coil-fed capability for volume runs.

- Finishes: mill, hot-dip galvanized, anodized aluminum, powder-coated, PVDF—supporting durability and brand-consistent colors. Edge margins and flatness are controlled for fabricator-friendly processing (shearing, bending, rolling, welding).

- As a dependable perforated metal mesh manufacturer, supplier, and exporter, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. provides both wholesale perforated metal mesh sheet supply and engineered custom perforated metal mesh sheet for OEMs, contractors, and distributors worldwide.

Benefits & Use Cases of Perforated Metal Mesh in Manufacturing of metal mesh and mesh products

Across factories, plants, and construction projects, perforated mesh solves multiple engineering challenges with a single product. It provides airflow and filtration for HVAC grilles and intake screens; acoustic attenuation in enclosures and wall/ceiling panels; impact resistance and visibility for machine guards; and lightweight rigidity for architectural facades, sunscreens, and balustrades. In process industries, custom perforated metal mesh supports sieving, drying, and dust collection where consistent open area and burr-free holes protect downstream equipment.

- Competitive advantages: high strength-to-weight ratio, predictable airflow, design flexibility (pattern, pitch, and open area), and excellent formability. With metal stainless steel perforated metal mesh, corrosion resistance and hygiene meet food, chemical, and outdoor standards.

- Supply models: wholesale perforated metal mesh and wholesale perforated metal mesh sheet for distributors; custom perforated metal mesh tailored to OEM dimensions, coatings, and packaging for assembly-line efficiency.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.—a seasoned perforated metal mesh factory—helps teams translate performance targets into precise patterns, ensuring the right balance of strength, weight, and flow for each application.

Cost, Maintenance & User Experience

Total cost of ownership hinges on durability, process fit, and supply reliability. Perforated mesh’s inherent rigidity cuts secondary stiffening, while coil-fed production and smart nesting help lower scrap, reducing unit cost for high-volume runs. Stainless and galvanized options extend life in corrosive or outdoor settings, improving ROI by cutting replacement cycles and unplanned downtime. Powder-coated finishes offer additional abrasion and UV protection with minimal maintenance.

- User feedback from fabricators in the fabricated metal products space highlights stable flatness, clean edges, and consistent open area—factors that speed bending, welding, and installation.

- Maintenance tips: periodic cleaning with neutral detergents, prompt touch-up on cut edges for coated steel, and proper fastener selection to avoid galvanic corrosion. These practices keep surfaces performing and presentable, even in demanding environments.

Sustainability & Market Trends in manufacturing

Perforated metal is inherently circular: it is durable in use and fully recyclable at end of life, aligning with LEED and corporate sustainability goals. Lightweighting, acoustic comfort, and energy-efficient ventilation are driving broader adoption in buildings, transportation, EVs, and data centers. Regulations increasingly favor materials with traceable origins and low-VOC finishes, while architects and OEMs seek product transparency and consistent quality documentation.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. positions itself as an eco-conscious partner by offering long-life substrates, efficient punching processes, and coating options that support reduced environmental impact, alongside robust packaging and logistics that minimize damage and waste.

- As global demand grows, partnering with experienced perforated metal mesh exporters and manufacturers ensures consistent quality and dependable lead times—key to de-risking supply chains in fast-moving markets.

Conclusion on Perforated Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

From airflow and acoustics to safety and aesthetics, perforated metal mesh delivers measurable value across the manufacturing, fabricated metal products, and metal mesh sectors. Whether you need a standard perforated metal mesh sheet, a custom perforated metal mesh for OEM integration, or reliable wholesale supply, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. is a trusted supplier, manufacturer, and exporter ready to support your specifications and delivery timelines.

- Contact us: email: sales@galvanizedmetalmesh.com

- Visit our website: https://www.galvanizedmeshproducts.com

- Explore the product page: Perforated Metal Mesh

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NewsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NewsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NewsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NewsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NewsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NewsNov.11,2025