-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Set . 05, 2025 16:31 De volta à lista

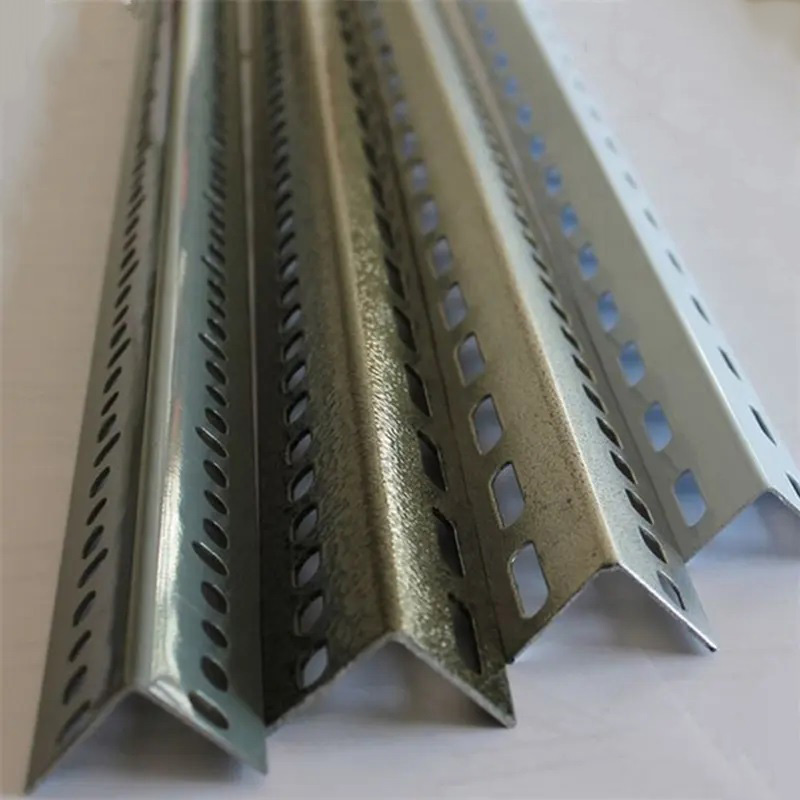

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

Navigating the Landscape of Stainless Steel Angle Manufacturing

The demand for robust, corrosion-resistant structural components drives innovation within the steel industry. Among these, stainless steel angles, particularly angle holes and angle bars, stand out for their versatility and durability. These components are critical in diverse applications, ranging from intricate architectural frameworks to heavy-duty industrial machinery. Identifying reputable fábricas de ângulo de aço inoxidável is paramount for ensuring product quality, adherence to specifications, and long-term project viability. This article delves into the intricacies of their production, technical specifications, application trends, and what to consider when sourcing these essential materials.

The selection of a reliable stainless steel angle factory directly impacts project timelines, structural integrity, and cost-effectiveness. Our focus is to provide B2B decision-makers and engineers with a comprehensive guide to understanding this critical product category.

Industry Trends and Market Dynamics for Stainless Steel Angles

The global market for stainless steel angles is experiencing sustained growth, propelled by several key factors. Increased infrastructure development, particularly in emerging economies, alongside stringent regulatory requirements for material durability and safety in sectors like petrochemicals and food processing, are significant drivers. There's a notable shift towards higher-grade stainless steels (e.g., Duplex and Super Duplex) due to their superior corrosion resistance and strength, even at elevated temperatures and in aggressive environments.

Technological advancements in manufacturing processes, such as precision rolling and automated punching, allow fábricas de ângulo de aço inoxidável to produce angles with tighter tolerances and more complex hole patterns. The emphasis on sustainability also influences material selection, with stainless steel’s recyclability and long service life making it an environmentally responsible choice. Leading fornecedores de ângulo de aço inoxidável are increasingly focusing on providing value-added services, including pre-fabrication, custom cutting, and surface finishing to meet diverse client needs. This competitive landscape highlights the importance for exportadores de ângulos com fenda de aço to offer comprehensive solutions beyond just the raw product.

Detailed Manufacturing Process Flow of Stainless Steel Angle Bars

The production of high-quality stainless steel angle bars involves a series of precise and controlled steps, ensuring that the final product meets rigorous industry standards and application requirements. Expertise in these processes distinguishes top-tier fábricas de ângulo de aço inoxidável.

Key Materials:

- Austenitic Stainless Steels: Grades 304/304L (most common, excellent corrosion resistance), 316/316L (superior corrosion resistance, especially against chlorides), 321 (titanium-stabilized for high-temperature applications).

- Duplex Stainless Steels: Grades like 2205 (high strength, excellent stress corrosion cracking resistance), offering a combination of austenitic and ferritic properties.

- Other Grades: Depending on specific project demands, various other grades can be utilized by specialized fábricas de ângulos com fenda de aço.

Manufacturing Process Steps:

- Raw Material Selection & Preparation: High-purity stainless steel billets or slabs are selected based on the required grade. These are inspected for defects and composition.

- Heating: Billets are uniformly heated in a furnace to a specific temperature (typically 1100-1250°C) to make them malleable for rolling.

- Hot Rolling: The heated billets pass through a series of rolling stands. Each stand progressively reduces the cross-sectional area and shapes the steel into the desired angle profile. This is the primary forming process for most structural angles.

- Cooling: The hot-rolled angles are cooled, often in a controlled manner, to prevent distortion and ensure metallurgical stability.

- Straightening: Angles are mechanically straightened to remove any warpage or curvature introduced during cooling.

- Slotted Hole Creation (for Angle Hole/Angle Bars): For products like Angle Hole/Angle Bars, precision punching or drilling machines (e.g., CNC machining) create uniform, accurately spaced slots or holes according to design specifications. This ensures compatibility with standard fastening systems.

- Deburring & Edge Finishing: Edges are deburred to remove sharp points and ensure safety and a clean finish.

- Heat Treatment (Optional but Common): Solution annealing is often performed for austenitic and duplex stainless steels. This involves heating the material to a high temperature followed by rapid cooling to optimize corrosion resistance and mechanical properties by dissolving carbides and relieving internal stresses.

-

Surface Finishing (Pickling & Passivation):

- Pickling: Immersion in an acid bath (e.g., nitric-hydrofluoric acid) removes scale and surface contaminants resulting from hot rolling and heat treatment.

- Passivation: A chemical treatment (e.g., nitric acid bath) enhances the passive chromium oxide layer on the surface, which is crucial for stainless steel's corrosion resistance.

- Quality Control & Testing: Rigorous testing ensures compliance with international standards (e.g., ISO 9001, ASTM A276, ASTM A484, EN 10088). This includes dimensional checks, chemical composition analysis (spectrometer), mechanical testing (tensile strength, yield strength, hardness, impact), and non-destructive testing (NDT) like visual inspection or dye penetrant testing.

- Marking & Packaging: Products are marked with grade, dimensions, and batch numbers. They are then securely packaged for shipment, often with protective wrapping to prevent damage during transit.

Image: Precision manufacturing in a stainless steel angle factory.

Testing Standards and Service Life:

Compliance with standards like ISO 9001 (Quality Management), ASTM A276/A484 (Standard Specification for Stainless Steel Bars and Shapes), and ANSI/ASME B16.9 (Fittings) ensures product reliability. The service life of stainless steel angles is exceptionally long, often exceeding 50 years, especially in well-maintained applications, far surpassing conventional carbon steel due to superior corrosion resistance. This inherent durability translates to significant long-term savings and reduced maintenance for target industries such as petrochemicals, metallurgy, and water supply & drainage.

Technical Specifications and Parameters of Angle Hole / Angle Bars

Understanding the technical specifications is crucial for engineers and procurement specialists when selecting angle bars from fábricas de ângulo de aço inoxidável. These parameters dictate suitability for specific load-bearing, environmental, and structural requirements.

Typical Product Specification Table (Stainless Steel Angle Hole / Angle Bars - Grade 304/304L)

| Parameter | Specification Range | Units |

|---|---|---|

| Material Grade | 304, 304L, 316, 316L, 2205 (Duplex) | - |

| Leg Size (Equal Angle) | 20x20 to 200x200 | milímetros |

| Grossura | 3 to 20 | milímetros |

| Comprimento | 3000 to 6000 (Standard) | mm (Custom available) |

| Tensile Strength (min) | 515 (304), 485 (316) | MPa |

| Yield Strength (min) | 205 (304), 170 (316) | MPa |

| Elongation (min) | 40 (304), 40 (316) | % |

| Hardness (max) | 201 HBW (304), 217 HBW (316) | HBW |

| Standard (Typical) | ASTM A276 / A484, EN 10088-3 | - |

| Hole/Slot Dimensions | Customizable (e.g., 9x25mm, 11x30mm) | milímetros |

It is imperative for procurement teams to verify these specifications with their chosen fornecedor de ângulos com fenda de aço to ensure exact material compliance and performance.

Application Scenarios and Target Industries

Stainless steel angle bars, particularly those with slotted holes, are foundational components across a myriad of industries due to their structural integrity and environmental resilience. Reputable fabricantes de ângulos com fenda de aço cater to these diverse needs.

- Petrochemical and Chemical Processing: Used for structural supports in highly corrosive environments, pipe racks, and equipment frames where resistance to acids, alkalis, and chlorides is critical.

- Water Supply & Drainage / Wastewater Treatment: Ideal for grates, platforms, stair treads, and structural elements in contact with water or effluent, preventing rust and degradation.

- Food & Beverage Processing: Frames for conveyor systems, storage racks, and processing equipment where hygiene, ease of cleaning, and corrosion resistance against food acids are paramount (often Grade 304L or 316L).

- Pharmaceutical Industry: Similar to food processing, stringent hygiene standards necessitate stainless steel for cleanroom structures, machinery frames, and laboratory setups.

- Construction and Architecture: Architectural accents, decorative elements, structural framing for curtain walls, railings, and bracing, particularly in coastal or humid regions.

- Marine and Offshore: Resists saltwater corrosion, making it suitable for boat construction, dock infrastructure, and offshore platforms.

- General Manufacturing: Machine guards, workbenches, shelving units, and general fabrication where a durable, long-lasting framework is required.

Image: Stainless steel angle bars supporting industrial infrastructure.

The versatility offered by different grades and customized dimensions ensures that stainless steel angles remain indispensable across these critical sectors, providing solutions where performance and longevity cannot be compromised.

Technical Advantages and Performance Benefits

Investing in stainless steel angles from leading fornecedores de ângulo de aço inoxidável offers a spectrum of technical advantages and long-term performance benefits crucial for demanding B2B applications.

- Superior Corrosion Resistance: Stainless steel, particularly grades like 316/316L, exhibits exceptional resistance to rust, pitting, and crevice corrosion, even in harsh chemical or marine environments. This significantly extends service life compared to galvanized or painted carbon steel.

- High Strength-to-Weight Ratio: Provides robust structural support without excessive bulk, allowing for more efficient designs and reduced material usage in some applications.

- Durability and Longevity: Its inherent resistance to degradation, coupled with excellent mechanical properties, ensures a minimal need for maintenance or replacement, resulting in lower total cost of ownership over decades.

- Hygiene and Cleanliness: The non-porous, smooth surface of stainless steel prevents bacterial growth and is easy to sterilize, making it ideal for pharmaceutical, medical, and food processing industries.

- Aesthetics: The polished or brushed finish of stainless steel offers a clean, modern appearance, which is desirable in architectural and design-focused applications.

- Temperature Resistance: Maintains mechanical properties across a wide range of temperatures, from cryogenic to elevated heat, making it suitable for various industrial settings.

- Energy Saving (Indirect): By minimizing downtime for repairs and replacements due to corrosion or failure, stainless steel components contribute to operational efficiency and reduce the energy footprint associated with maintenance and material production cycles.

These advantages underscore why stainless steel angles are often the preferred choice for critical structural applications where reliability and long-term performance are non-negotiable.

Vendor Comparison: Choosing the Right Stainless Steel Angle Factory

Selecting the optimal `stainless steel angle factory` or `exportador de ângulos com fenda de aço` involves more than just comparing prices. A holistic evaluation considering quality, reliability, and service is paramount.

Key Comparison Criteria for Stainless Steel Angle Suppliers:

| Criterion | Importance | Considerations |

|---|---|---|

| Material Quality & Traceability | High | Certifications (MTRs), mill source, adherence to ASTM/EN standards. |

| Manufacturing Precision | High | Tolerances, hole accuracy, straightness, finish quality. |

| Certifications & Compliance | Critical | ISO 9001, specific product certifications, environmental compliance. |

| Customization Capabilities | Medium-High | Ability to produce non-standard sizes, grades, hole patterns, pre-fabrication. |

| Lead Times & Logistics | High | Reliability of delivery schedules, shipping options, inventory availability. |

| Customer Support & After-Sales | High | Technical assistance, responsiveness, issue resolution, warranty. |

| Pricing & Value Proposition | Medium | Balance of cost with quality, service, and long-term reliability. Avoid solely price-driven decisions. |

A thorough due diligence process, including facility audits and reference checks, is recommended when evaluating potential `fábricas de ângulos com fenda de aço` or `fabricantes de ângulos com fenda de aço`.

Customized Solutions and Fabrication Services

Beyond standard offerings, many advanced `fábricas de ângulo de aço inoxidável` provide customized solutions, significantly enhancing project efficiency and reducing on-site fabrication costs.

- Bespoke Dimensions: Production of angle bars with non-standard leg sizes, thicknesses, and lengths to perfectly fit unique design requirements.

- Specific Grades and Alloys: Sourcing or manufacturing angles from specialized stainless steel grades (e.g., specific Duplex, Super Duplex, or Nickel alloys) for extreme environmental conditions.

- Precision Hole/Slot Patterns: CNC punching and drilling capabilities to create custom hole sizes, shapes, and spacing, enabling seamless integration with other components.

- Surface Finishes: Offering various surface treatments beyond standard pickling and passivation, such as electropolishing for ultra-hygienic applications, or specific aesthetic finishes.

- Pre-Fabrication and Assembly: Some `fábricas de ângulos com fenda de aço` can provide cut-to-length, deburred, welded, or even partially assembled components, minimizing on-site work and installation time.

Image: Precision-cut stainless steel angle bars for a specialized project.

These tailored services from skilled `fabricantes de ângulos com fenda de aço` provide significant value, ensuring that project specifications are met precisely and efficiently.

Application Case Studies: Real-World Impact

The practical application of stainless steel angles in challenging environments underscores their value and the importance of reliable `fornecedores de ângulo de aço inoxidável`.

-

Case Study 1: Coastal Wastewater Treatment Plant Upgrade

A major municipal wastewater treatment facility located near a coastline faced severe corrosion issues with its existing carbon steel structural components due to chloride exposure and aggressive chemical environments. The facility underwent an upgrade, replacing all structural angle supports, grating frames, and handrail components with Grade 316L stainless steel angle bars supplied by a leading `stainless steel angle factory`. The new stainless steel framework provided superior corrosion resistance, eliminating the need for frequent painting and repairs. This resulted in projected maintenance cost savings of over 40% annually and significantly extended the operational lifespan of the critical infrastructure, demonstrating the "energy saving" aspect through reduced material and labor consumption for maintenance.

-

Case Study 2: Pharmaceutical Cleanroom Expansion

A global pharmaceutical company required an expansion of its sterile manufacturing cleanroom facilities. The project demanded materials that met stringent hygiene standards, could withstand frequent chemical sterilization, and offer structural integrity for specialized equipment. Custom-fabricated 304L stainless steel angle holes, precision-cut and electropolished by an experienced `fabricante de ângulos com fenda de aço`, were used for shelving units, equipment frames, and wall panel supports. The high-grade stainless steel ensured compliance with FDA regulations, prevented microbial contamination, and provided a robust, easy-to-clean infrastructure, critical for pharmaceutical production.

-

Case Study 3: Large-Scale Industrial Conveyor System for Mining

A new mining operation required an extensive conveyor belt system in a highly abrasive and dusty environment. Standard steel angles were proving insufficient due to rapid wear and rust. A `stainless steel angle factory` provided heavy-duty Duplex 2205 stainless steel angle bars for the primary support structures of the conveyor system. The Duplex grade offered superior abrasion resistance and excellent resistance to localized corrosion, even with mineral dust and occasional moisture. This choice minimized structural failures, reduced unscheduled downtime for maintenance, and significantly extended the life cycle of the conveyor system, leading to enhanced operational efficiency.

These cases exemplify how the technical advantages of stainless steel angles, when sourced from knowledgeable `exportadores de ângulos com fenda de aço`, translate into tangible benefits like reduced maintenance, improved safety, and extended operational life.

Trustworthiness and Support: Our Commitment

As a reputable `stainless steel angle factory`, our commitment extends beyond product delivery to ensuring client satisfaction through robust support structures and transparent policies.

Image: Rigorous quality checks for stainless steel angle bars.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom stainless steel angles?

A1: Standard stock items typically ship within 3-5 business days. Custom orders, depending on complexity and volume, usually range from 2-4 weeks. Expedited options are available upon request.

Q2: What certifications do your products hold?

A2: All our stainless steel angle bars conform to international standards such as ASTM A276/A484 and EN 10088. Our manufacturing processes are ISO 9001 certified, ensuring consistent quality. Material Test Reports (MTRs) are provided with every shipment for full traceability.

Q3: How do you ensure the quality of slotted holes?

A3: We utilize advanced CNC punching and drilling machinery for precise hole creation. Each batch undergoes rigorous dimensional inspection and visual checks to ensure accurate sizing, spacing, and clean, burr-free edges.

Q4: Can you provide guidance on material selection for specific applications?

A4: Yes, our team of technical experts can provide detailed consultation on the optimal stainless steel grade and specifications for your particular application, considering environmental factors, load requirements, and budget constraints.

Lead Time & Fulfillment

We maintain a substantial inventory of common stainless steel angle sizes and grades to facilitate rapid dispatch. For highly customized orders, our streamlined production process, coupled with efficient logistics, ensures competitive lead times without compromising quality. We provide real-time updates on order status and collaborate with trusted shipping partners for reliable global delivery.

Warranty Commitments

All our stainless steel angle products are backed by a comprehensive warranty against manufacturing defects and material non-conformance. Our commitment to quality ensures that products supplied by our `stainless steel angle factory` meet or exceed industry specifications for performance and durability. Specific warranty terms are provided with each quotation and order.

Customer Support

Our dedicated customer support team is available to assist with inquiries, technical specifications, order tracking, and after-sales service. We offer multi-channel support via phone, email, and a dedicated online portal. Our technical specialists provide expert advice, ensuring you receive the precise stainless steel angle solutions for your projects. We pride ourselves on responsive and knowledgeable service, fostering long-term partnerships with our clients.

Conclusion

The demand for high-performance structural materials continues to grow, positioning stainless steel angles as indispensable components in various critical industries. From intricate manufacturing processes to diverse application scenarios, the advantages of these products—superior corrosion resistance, durability, and versatility—are unmatched. Partnering with a reputable `stainless steel angle factory` that demonstrates expertise, experience, authoritativeness, and trustworthiness is essential for successful project outcomes. By carefully evaluating technical specifications, manufacturing capabilities, and comprehensive support services, B2B decision-makers can ensure they procure stainless steel angle bars that meet the highest standards of quality and performance, delivering long-term value and reliability.

References

- ASM International. "Stainless Steels Handbook." Materials Park, OH, 2018.

- ASTM International. "A276/A276M-17: Standard Specification for Stainless Steel Bars and Shapes." West Conshohocken, PA, 2017.

- ISO. "ISO 9001:2015 - Quality management systems — Requirements." Geneva, Switzerland, 2015.

- The European Stainless Steel Development Association (Euro Inox). "Stainless Steel in Construction – The Designer’s Handbook." Brussels, Belgium, 2010.

- American Iron and Steel Institute (AISI). "Stainless Steel in Architecture, Building & Construction." Washington D.C., 2021.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NotíciasNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NotíciasNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NotíciasNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NotíciasNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NotíciasNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NotíciasNov.11,2025