-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Out . 09, 2024 02:45 Back to list

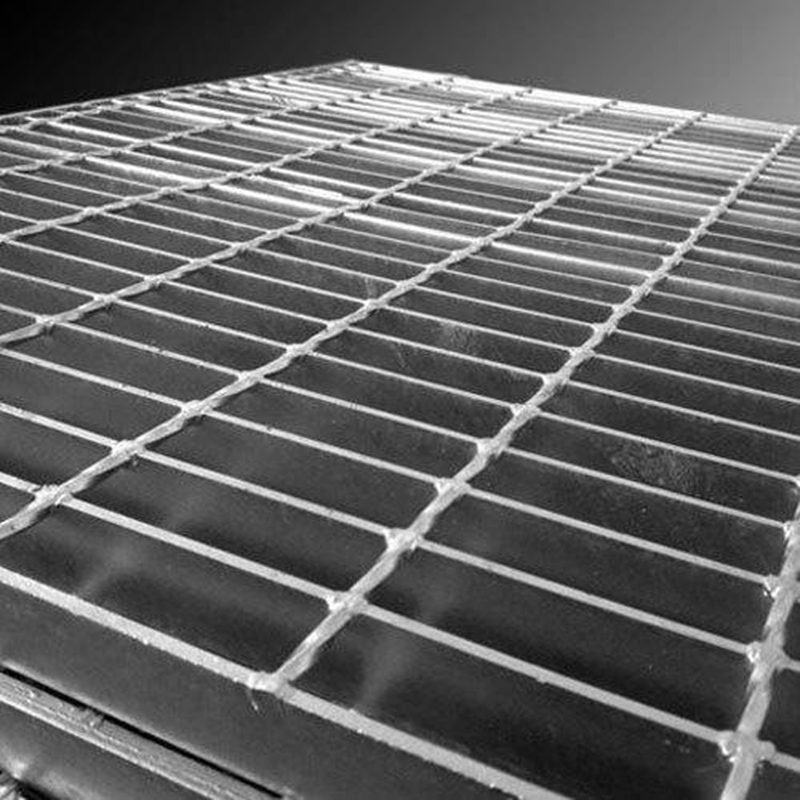

stainless steel grating factory

The Versatility and Applications of Stainless Steel Grating Insights from a Leading Factory

Stainless steel grating is an essential material used in various industries, known for its durability, strength, and resistance to corrosion

. A stainless steel grating factory specializes in manufacturing high-quality grating products that cater to diverse applications, making it a crucial player in the construction, industrial, and architectural sectors.One of the primary advantages of stainless steel grating is its ability to withstand harsh environmental conditions. Unlike other materials, stainless steel exhibits excellent resistance to corrosion, making it ideal for outdoor use and in environments exposed to moisture and chemicals. This characteristic is particularly beneficial for industries such as petrochemical, wastewater treatment, and food processing, where the need for hygiene and resilience against corrosive substances is paramount.

At a stainless steel grating factory, the manufacturing process involves a combination of cutting, welding, and finishing techniques to produce grating that meets specific industry standards. The factory operates with advanced machinery and skilled labor to ensure precision in each step of production. Common types of stainless steel grating produced include welded, swaged, and pressed grating, which can be tailored to fit various applications.

In construction, stainless steel grating serves multiple purposes. It can be used as walkways, platforms, and stair treads. The open design of grating allows for excellent drainage, making it a suitable choice for areas that require quick water runoff. Additionally, its superior load-bearing capabilities make it a trusted option for heavy-duty applications, such as in manufacturing plants and warehouses.

stainless steel grating factory

Architecturally, stainless steel grating is increasingly used in modern designs. It contributes to aesthetic appeal while maintaining functionality. Designers often incorporate stainless steel grating in flooring, facades, and railings, creating a sleek and contemporary look. Moreover, its ability to blend seamlessly with other materials allows for creative and innovative design solutions.

Another significant application of stainless steel grating is in the transportation sector. Grating is commonly installed on bridges, loading docks, and walkways to ensure safety and accessibility. The non-slip surface of stainless steel grating provides secure footing, reducing the risk of accidents in high-traffic areas. Moreover, its strength and durability make it a long-lasting solution that minimizes maintenance costs over time.

Environmental sustainability is also a consideration in the production of stainless steel grating. Many factories are adopting eco-friendly practices, utilizing recycled stainless steel and energy-efficient manufacturing processes. This commitment to sustainability not only reduces the carbon footprint but also appeals to environmentally conscious consumers and businesses.

In summary, a stainless steel grating factory plays a vital role in producing a versatile material that finds applications across various industries. From construction to transportation and architectural design, stainless steel grating offers an array of advantages, including corrosion resistance, strength, and aesthetic appeal. As industries continue to evolve, the demand for high-quality, durable materials like stainless steel grating will undoubtedly grow, positioning these factories as indispensable players in the market. With a focus on innovation and sustainability, they are well-equipped to meet the challenges of the future, contributing to safer, more efficient, and environmentally responsible solutions for a wide range of applications.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025