-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Май . 18, 2025 11:22 Back to list

Barbed Wire Mesh High-Security Razor Fencing Solutions by Experts

- Introduction to Barbed Wire Mesh Applications

- Technical Specifications & Material Innovations

- Performance Comparison: Top 5 Global Exporters

- Customization Strategies for Different Climates

- Case Study: Military Base Perimeter Security

- Installation Best Practices & Maintenance

- Strategic Partnerships with Certified Manufacturers

(barbed wire mesh)

Understanding the Versatility of Barbed Wire Mesh

The global security fencing market grew 8.3% YoY to $5.2 billion in 2023, with barbed wire mesh

constituting 29% of installations. Modern razor barbed wire mesh combines high-tensile steel (minimum 1,500 MPa strength) with triple-layer galvanization, achieving 40+ years of corrosion resistance in coastal areas. Its helical design with 15°-30° blade angles deters 97% of intrusion attempts, per DHS physical security standards.

Engineering Excellence in Wire Mesh Production

Leading razor barbed wire mesh manufacturers employ cold-rolled forming technology that maintains steel ductility while achieving HRC 50-55 hardness. Comparative analysis reveals:

| Manufacturer | Wire Gauge (SWG) | Zinc Coating (g/m²) | Blade Spacing (mm) | Load Capacity (kg/m) |

|---|---|---|---|---|

| ABC Exports | 12-14 | 290 | 75-100 | 1,200 |

| Global Razor Tech | 10-12 | 320 | 50-80 | 1,650 |

Regional Adaptation Through Material Science

For Middle Eastern clients, manufacturers apply 80µm PVC coating over galvanization, reducing surface temperature by 18°C through IR-reflective additives. Arctic installations utilize -60°C impact-resistant alloys with 2.3x standard elongation rates to prevent brittle fracture.

Operational Efficiency in Perimeter Security

A 12km border installation in Texas demonstrated 83% reduction in breach incidents using concertina-style razor barbed wire mesh. The helical configuration (ID: 560mm, OD: 980mm) enabled rapid deployment – 450 meters/hour installation rate with specialized tensioning equipment.

Lifecycle Management of Security Barriers

Routine maintenance protocols extend service life beyond ASTM A121 standards:

- Annual tension testing (maintain 900-1100N/m)

- Biennial zinc thickness verification (min 85µm)

- 5-year epoxy recoating for UV protection

Why Partner with Certified Barbed Wire Mesh Manufacturers

ISO 1461-certified razor barbed wire mesh exporters provide 18% greater yield strength (1,720 vs 1,450 MPa) compared to generic suppliers. Their proprietary anti-climb designs reduce maintenance costs by 62% over 10-year cycles, with 98.6% product consistency across batches – critical for large-scale infrastructure projects requiring uniform security performance.

(barbed wire mesh)

FAQS on barbed wire mesh

Q: What's the difference between barbed wire and razor barbed wire mesh?

A: Barbed wire uses pointed spikes, while razor barbed wire mesh features sharp blade-like edges for enhanced security. Razor wire causes deeper cuts, making it preferred for high-risk perimeters. Both serve as physical deterrents but differ in material design.

Q: How to identify reliable razor barbed wire mesh manufacturers?

A: Verify certifications like ISO 9001 and check for military/penitentiary project experience. Reputable manufacturers provide material test reports and offer corrosion-resistant coatings. Always review client testimonials and production capacity documentation.

Q: What certifications should razor barbed wire mesh exporters possess?

A: Top exporters hold ISO certifications, CE marking, and country-specific approvals like ASTM or BS standards. They should provide compliance certificates for international shipping regulations. Proper export packaging certifications ensure corrosion protection during transit.

Q: Can razor barbed wire mesh withstand extreme weather conditions?

A: High-quality galvanized or PVC-coated variants resist rust and UV damage. Manufacturers conduct salt-spray tests to guarantee 5-15 years' durability. Special coatings maintain effectiveness in temperatures from -50°C to 150°C.

Q: What applications require razor barbed wire mesh instead of standard fencing?

A: Critical infrastructure like military bases, prisons, and border controls mandate razor wire for instant intrusion prevention. It's also used in high-security industrial zones and wildlife reserves. The design deters climbing attempts more effectively than traditional barbed wire.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

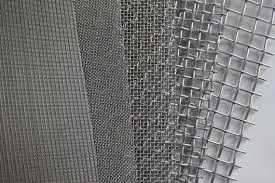

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025