-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Окт . 14, 2024 14:45 Back to list

Concertina Razor Wire Production Facility and Its Innovative Security Solutions

The Concertina Razor Wire Factory Enhancing Security with Precision Engineering

In an era where security is of utmost importance, the demand for effective perimeter defense solutions has reached unprecedented levels. One such innovation that has become synonymous with security is concertina razor wire. The concertina razor wire factory plays a pivotal role in this industry, providing high-security fencing systems that deter unauthorized access while ensuring durability and reliability.

Concertina wire, often referred to as razor wire, consists of sharp edges or fine wire blades arranged in a coiled configuration. Its design enables it to be deployed easily, covering vast areas efficiently, and creating an intimidating barrier that is difficult to breach. The unique configuration of the wire not only enhances its strength but also allows for quick installation and maintenance, making it a preferred choice for many security applications.

At the heart of a concertina razor wire factory lies advanced machinery and skilled craftsmanship. The manufacturing process begins with the procurement of high-quality steel wire, specifically treated to withstand adverse environmental conditions. This raw material undergoes rigorous quality control checks to ensure it meets the stringent standards laid down by the industry. Following this, the wire is processed to form the characteristic spiral shape of concertina wire, a process that requires precision and expertise. Machines designed to create sharp edges are utilized, ensuring that each coil maintains the necessary deterrent ability.

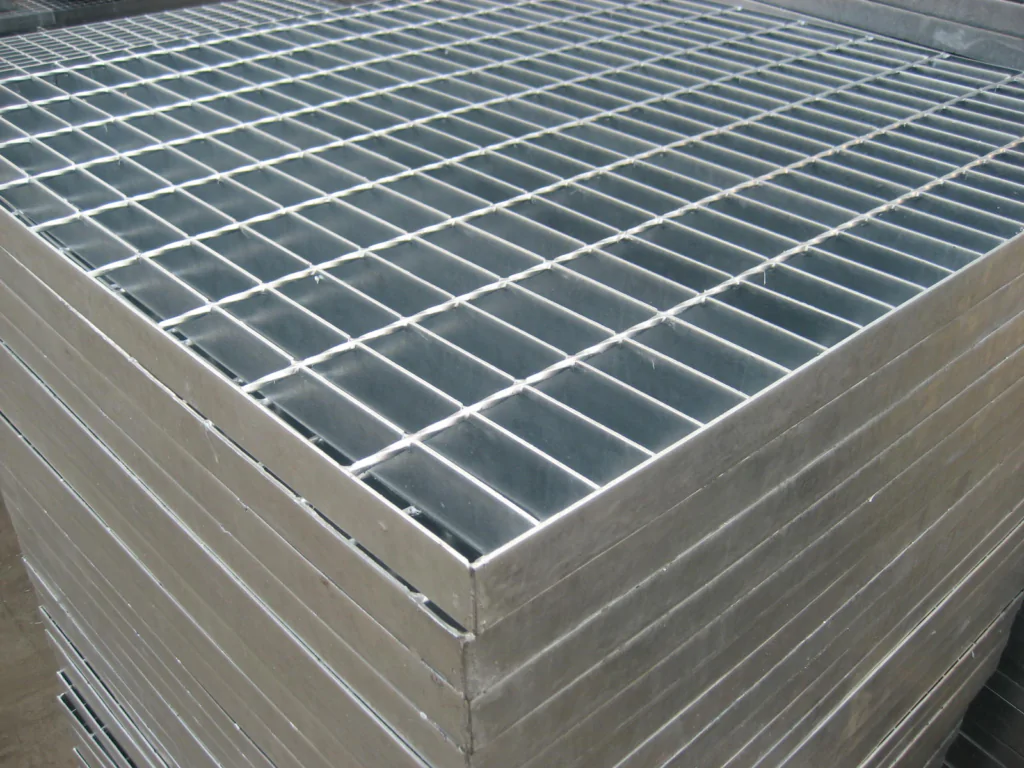

The production of concertina razor wire not only focuses on strength and durability but also considers the visual appeal of the product. A professional factory invests in technology that can coat the wire with various finishes, such as galvanized or painted options, to provide corrosion resistance and enhance aesthetic value. This is particularly important for installations in urban areas where visual impact is a consideration for property owners.

concertina razor wire factory

One of the key aspects that sets a concertina razor wire factory apart is its commitment to customization. Security needs vary widely depending on the application, whether it be in prisons, military installations, industrial sites, or residential areas. A proficient factory is capable of producing concertina wire in different lengths, widths, and configurations, tailored to the specific requirements of clients. This adaptability has led to innovations in the design of concertina wire systems, including the development of integrated alarm systems and other technological enhancements that provide added layers of security.

The deployment of concertina razor wire, produced in such specialized factories, offers numerous benefits beyond just security. The physical presence of razor wire acts as an effective psychological deterrent, often dissuading potential trespassers from attempting to breach secured areas. Additionally, the use of concertina wire significantly reduces the need for extensively built walls or fences, which can be both time-consuming and costly to erect. This makes concertina wire an economically viable option for many organizations looking to bolster their security infrastructure without overspending.

Environmental considerations also play an increasingly important role in the operations of modern concertina razor wire factories. Manufacturers are now exploring sustainable practices, such as recycling scrap metal and minimizing waste, contributing to a more sustainable manufacturing process. Furthermore, eco-friendly coatings and treatments are being developed to ensure that while security needs are met, they do not compromise the environment.

In conclusion, the concertina razor wire factory is instrumental in addressing the growing security demands of our society. By focusing on quality, customization, and sustainability, these factories not only produce effective security solutions but also adapt to the changing landscapes of security needs. As we move forward, the importance of innovative security products like concertina razor wire will undoubtedly continue to rise, solidifying the factory’s role as a crucial player in the field of security engineering.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025