-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Дек . 02, 2024 03:26 Back to list

Galvanized Welded Wire Mesh Manufacturing Plants and Their Production Processes

The Importance and Applications of Galvanized Welded Wire Mesh

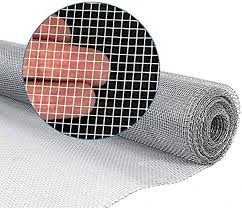

Galvanized welded wire mesh has emerged as a vital component in various industries due to its durability, strength, and versatility. This type of wire mesh consists of steel wires that are welded together at intersections and then coated with a layer of zinc for corrosion resistance. The result is a reliable and long-lasting product suitable for a range of applications.

Manufacturing Process

The production of galvanized welded wire mesh involves a meticulous process that begins with high-quality steel wires. These wires are first drawn to the desired gauge and then cut to the required lengths. The wires are organized into sheets or rolls and welded together at their intersections using advanced welding techniques. The final step is galvanization, where the welded mesh is coated with molten zinc to create a protective layer that prevents rust and degradation.

Benefits of Galvanized Welded Wire Mesh

1. Corrosion Resistance One of the primary advantages of galvanized welded wire mesh is its excellent resistance to corrosion. The zinc coating provides a protective barrier against moisture and other environmental factors that can lead to rust. This makes it ideal for outdoor applications or areas with high humidity.

2. High Strength The welding process enhances the tensile strength of the mesh, making it suitable for applications where structural integrity is essential. It can withstand heavy loads and resist deformation, which is crucial in construction and industrial uses.

3. Easy Installation Galvanized welded wire mesh is easy to cut, bend, and shape, allowing for straightforward installation. It can be used in various configurations, making it adaptable to different projects and requirements.

4. Cost-Effectiveness While the initial investment might be higher than some alternatives, the longevity and durability of galvanized welded wire mesh result in reduced maintenance costs over time. Its longevity makes it a cost-effective solution in the long run.

galvanized welded wire mesh factories

Applications

Galvanized welded wire mesh finds extensive use across multiple sectors. Here are some of its key applications

1. Construction In the construction industry, galvanized welded wire mesh is commonly used for reinforcing concrete in floors, walls, and pavements. It enhances the overall strength and stability of concrete structures.

2. Agriculture Farmers utilize welded wire mesh for creating fencing to keep livestock secure and protect crops from wildlife. It is also used in greenhouses to support plants and as a trellis for climbing vegetation.

3. Architecture In architectural design, galvanized welded wire mesh is often used for decorative purposes in facades, railings, and partitions. Its aesthetic appeal combined with functionality makes it popular among architects and designers.

4. Security Welded wire mesh provides an effective solution for security fencing around properties, construction sites, and industrial facilities. Its robust nature makes it difficult to breach, serving as a deterrent against intruders.

5. Industrial Applications In industrial settings, galvanized welded wire mesh is used for storage cages, shelves, and enclosures. Its strength and durability cater to the rigorous demands of various manufacturing processes.

Conclusion

As the demand for durable and reliable materials continues to rise, galvanized welded wire mesh stands out as a preferred choice across various industries. With its exceptional benefits, including corrosion resistance and high strength, it is poised to play an essential role in the future of construction, agriculture, security, and more. As manufacturers continue to innovate and improve production methods, we can expect even greater advancements in the quality and applications of galvanized welded wire mesh. Whether in urban development or rural settings, its influence will remain significant, ensuring safety, efficiency, and sustainability for generations to come.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025