-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Мар . 07, 2025 04:50 Back to list

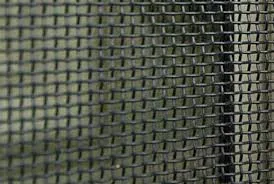

high quality crimped wire mesh

When seeking to enhance the durability and structural integrity of concrete constructions, high quality concrete reinforcement wire mesh becomes indispensable. This integral material plays a pivotal role in modern construction, marrying the expertise of engineering with the realities of robust building requirements. For those invested in understanding the nuances of concrete reinforcement wire mesh, it's crucial to explore its multifaceted benefits, applications, and how to ensure you're utilizing the highest quality available.

Authoritative voices in the construction sector underscore the mesh's utility in enhancing the load-bearing capacity of slabs. By conferring additional tensile strength, reinforcement mesh supports heavier loads, a feature indispensable for high-traffic areas or industrial settings where heavy machinery operation is commonplace. Moreover, the use of mesh in walls and columns fortifies the building's overall structural integrity against natural elements such as seismic activities, making it an essential component in modern earthquake-resistant designs. For those ensuring trustworthiness in product selection, looking at industry standards and certifications provides peace of mind. Premium concrete reinforcement wire meshes comply with ASTM (American Society for Testing and Materials) standards, which denote high tensile strength, durability, and resistance properties. Selecting a mesh that meets or exceeds these standards is a testimony to its reliability and performance, fulfilling its role in safety and stability. Moreover, manufacturers often offer expertise through technical support and consultancy services, helping project managers and engineers choose the right type and configuration of mesh for their specific needs. This collaboration can prevent potential missteps in construction, ensuring each wire mesh application achieves optimal results. Ultimately, the investment in high quality concrete reinforcement wire mesh is not merely a choice but a necessity for those prioritizing safety, cost-efficiency, and structural excellence. With proper selection and application, constructions benefit from enhanced lifespan, reduced maintenance, and a solid reputation built on the enduring integrity of the structures.

Authoritative voices in the construction sector underscore the mesh's utility in enhancing the load-bearing capacity of slabs. By conferring additional tensile strength, reinforcement mesh supports heavier loads, a feature indispensable for high-traffic areas or industrial settings where heavy machinery operation is commonplace. Moreover, the use of mesh in walls and columns fortifies the building's overall structural integrity against natural elements such as seismic activities, making it an essential component in modern earthquake-resistant designs. For those ensuring trustworthiness in product selection, looking at industry standards and certifications provides peace of mind. Premium concrete reinforcement wire meshes comply with ASTM (American Society for Testing and Materials) standards, which denote high tensile strength, durability, and resistance properties. Selecting a mesh that meets or exceeds these standards is a testimony to its reliability and performance, fulfilling its role in safety and stability. Moreover, manufacturers often offer expertise through technical support and consultancy services, helping project managers and engineers choose the right type and configuration of mesh for their specific needs. This collaboration can prevent potential missteps in construction, ensuring each wire mesh application achieves optimal results. Ultimately, the investment in high quality concrete reinforcement wire mesh is not merely a choice but a necessity for those prioritizing safety, cost-efficiency, and structural excellence. With proper selection and application, constructions benefit from enhanced lifespan, reduced maintenance, and a solid reputation built on the enduring integrity of the structures.

Next:

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025