-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ноя . 10, 2024 05:47 Back to list

Stainless Steel Wire Mesh Production and Quality Assurance by Leading Manufacturer

The Essential Role of Stainless Steel Wire Mesh Manufacturers

Stainless steel wire mesh is an essential material across various industries, renowned for its strength, durability, and versatile applications. From filtering solutions to architectural designs, stainless steel wire mesh serves important functions in many sectors, including food processing, construction, wastewater treatment, and more. Behind this indispensable product lies the expertise and innovation of stainless steel wire mesh manufacturers.

Understanding Stainless Steel Wire Mesh

Stainless steel wire mesh is crafted from high-quality stainless steel, which is known for its resistance to corrosion and rust. This material’s inherent properties make it suitable for use in both indoor and outdoor environments. The mesh comes in various weave patterns and sizes, allowing manufacturers to meet specific customer demands. Common weave types include plain weave, twill weave, and Dutch weave, each offering unique characteristics ideal for different applications.

The Manufacturing Process

The manufacturing of stainless steel wire mesh begins with the selection of premium grade stainless steel wire. The wire is drawn to the desired diameter and then woven into a mesh pattern using advanced machinery. The weaving process is crucial, as it determines the strength, flexibility, and functionality of the final product.

After weaving, the mesh undergoes various treatments such as cleaning, annealing, and finishing to ensure optimal performance. These processes enhance the mesh’s resistance to corrosion and improve its overall finish. Quality control is a vital component throughout manufacturing, as manufacturers must adhere to stringent standards to deliver products that meet customer expectations.

Applications of Stainless Steel Wire Mesh

The applications of stainless steel wire mesh are numerous and varied. In the food processing industry, for instance, it is used in filtration systems to separate solids from liquids, ensuring the safety and quality of food products. It is also employed in the manufacturing of equipment such as sieves, screens, and strainers.

In the construction industry, stainless steel wire mesh is used for reinforcing concrete, providing added strength and durability to structures. Its architectural applications include decorative elements, façades, and partition walls, where aesthetics and safety are paramount.

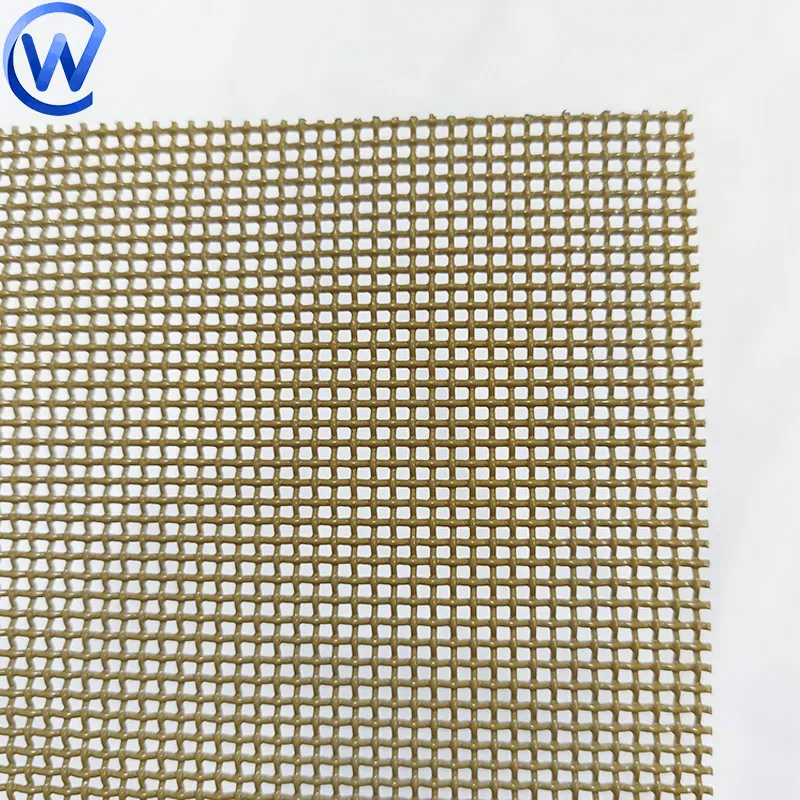

stainless steel wire mesh manufacturer

In the mining and mineral processing industries, stainless steel wire mesh plays a role in the classification and separation of materials. Its properties make it ideal for use in harsh environments, where durability and resistance to abrasion are necessities.

The Importance of Quality in Manufacturing

The success of industries relying on stainless steel wire mesh hinges on the quality of the products they use. Reputable manufacturers prioritize quality control at every stage of production. They typically follow international standards such as ISO 9001, ensuring that their products are consistently reliable and capable of meeting various industry requirements.

Moreover, skilled professionals work to innovate new materials and manufacturing processes. This focus on continuous improvement allows manufacturers to develop wire mesh products that incorporate the latest technologies, offering enhanced features like better filtration capabilities, increased resistance to chemicals, and improved structural integrity.

Choosing a Reliable Manufacturer

For businesses seeking stainless steel wire mesh, selecting a reliable manufacturer is critical. Considerations include the manufacturer’s track record, product range, customization options, and customer support. A reputable manufacturer will be able to provide references and samples to demonstrate their capabilities.

Additionally, look for manufacturers that emphasize sustainability in their practices. Many modern manufacturers are committed to reducing their environmental footprint and utilizing eco-friendly materials and processes. This commitment not only benefits the environment but can also enhance the appeal of their products to increasingly eco-conscious consumers.

Conclusion

Stainless steel wire mesh is a vital component in a multitude of applications, with its manufacturers playing a crucial role in ensuring its quality and availability. By understanding the manufacturing processes, applications, and the importance of quality, businesses can make informed choices when selecting their suppliers. Ultimately, investing in high-quality stainless steel wire mesh from reliable manufacturers will lead to better performance, enhanced durability, and long-lasting results in various applications. As industries continue to evolve, the role of these manufacturers will remain pivotal in meeting the growing demands and maintaining the high standards expected by consumers.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025