-

+86 15030157877

-

sales@galvanizedmetalmesh.com

නොවැ. . 07, 2024 19:18 Back to list

Top Manufacturers of 12.5% Gauge Barb Wire for Various Applications and Needs

The Role of 12.5% Gauge Barb Wire in Various Applications

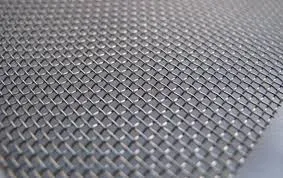

Barb wire, often referred to as barbed wire, is a type of fencing wire that is twisted with sharp edges to deter animals and unauthorized individuals from trespassing. Among the various gauges available, the 12.5% gauge barb wire is notable for its robustness and versatility, making it a popular choice among manufacturers and consumers alike.

Understanding Gauge and Its Significance

Gauge refers to the thickness of the wire used in barb wire fencing. The term gauge is an important metric in wire manufacturing; the lower the gauge number, the thicker the wire. A 12.5% gauge indicates a wire that balances flexibility and strength, making it an ideal option for various fencing needs. Its thickness allows for durability while still being manageable during installation.

Manufacturing Process of 12

.5% Gauge Barb WireManufacturers of 12.5% gauge barb wire typically begin with high-quality steel because of its strength and resistance to weather elements. This raw material undergoes several processes, including drawing, which reduces the diameter and increases the length of the wire. The wire is then shaped into coils and twisted to form the barbs, which are strategically placed to create an effective barrier. Once shaped, coatings such as galvanized or PVC are often applied to enhance corrosion resistance and prolong the lifespan of the wire.

Applications of 12.5% Gauge Barb Wire

12.5 gauge barb wire manufacturers

The versatility of 12.5% gauge barb wire allows it to be employed in a wide array of settings. One of its primary uses is in agricultural fencing. Farmers utilize this type of fencing to protect livestock and crops from being invaded by wild animals or other unauthorized creatures. The sharp barbs act as a deterrent, ensuring that livestock remains safe and containment is effectively maintained.

In addition to agricultural uses, 12.5% gauge barb wire is also prevalent in security fencing. Businesses—especially those in industries like warehousing, construction, and military applications—often rely on this type of fencing to secure their perimeters. The intimidating design of the barbed wire not only deters intruders but also provides a visual warning of restricted areas.

Moreover, this gauge of barb wire finds utility in residential applications as well. Homeowners looking to enhance their security often incorporate barbed wire fencing around their properties. While aesthetics are a consideration, the primary function remains deterrence, ensuring that potential trespassers think twice before attempting to breach the property.

Environmental Impact and Sustainability

As with many industrial products, the manufacturing of 12.5% gauge barb wire raises questions regarding sustainability and environmental impact. Manufacturers are increasingly aware of their environmental footprint and are seeking ways to mitigate it. Practices such as recycling steel and reducing waste during production are gradually gaining traction. Additionally, using eco-friendly coatings instead of traditional paints can lessen the environmental impact.

Conclusion

The significance of 12.5% gauge barb wire in fencing applications cannot be understated. Its durability, versatility, and effectiveness make it a preferred choice for agricultural, industrial, and residential fencing solutions. As the demand for security and animal containment continues to rise, manufacturers are poised to adapt their practices, ensuring that they meet both consumer needs and environmental responsibilities. Ultimately, the evolution of barb wire production, particularly the 12.5% gauge, reflects broader trends in materials science and sustainable manufacturing practices, securing its place as a vital element in modern fencing solutions.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025