-

+86 15030157877

-

sales@galvanizedmetalmesh.com

පෙබ. . 11, 2025 13:47 Back to list

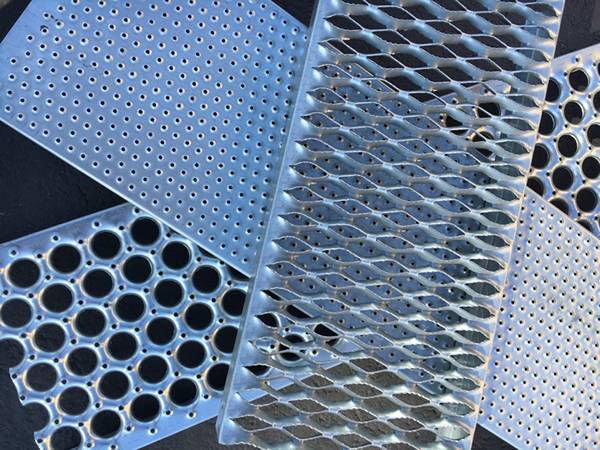

custom woven wire mesh

Custom woven wire mesh has become a transformative solution in modern industrial and architectural applications, offering unparalleled versatility and functionality. This intricate material, considered an art form in itself due to the precision required in its creation, provides extensive customization options for diverse needs, ensuring that industrial, commercial, or aesthetic requirements are met with exactitude.

Enhancing Authoritativeness in Wire Mesh Solutions When seeking custom woven wire mesh solutions, it is imperative to consult with manufacturers that possess not only technical expertise but also an authoritative presence in the industry. Experienced manufacturers bring a wealth of knowledge that includes understanding the environmental factors affecting material choice, recognizing the nuances of various weaving techniques, and providing insights into potential applications and innovations. An authoritative manufacturer prioritizes quality assurance, conducting rigorous testing to adhere to international standards and certifications. This commitment to quality builds trust, assuring clients that their investment will yield a reliable and effective product. Manufacturers that invest in research and development also stay at the forefront of innovation, continually enhancing the capabilities of woven wire mesh to meet evolving industry challenges. Building Trust and Credibility Trust in custom woven wire mesh solutions extends beyond product quality—it encompasses the entire customer experience. Reputable suppliers provide comprehensive support, from initial consultation and design customization to final production and installation guidance. This holistic approach ensures that clients receive precisely what they need, backed by expert recommendations and support. Furthermore, reputable companies often offer sustainable production practices, enhancing their credibility by reducing environmental impact. By choosing suppliers that prioritize sustainability, clients can align their purchases with broader corporate responsibility goals, thereby adding value to their own brand reputation. In conclusion, custom woven wire mesh represents a synergy of art and engineering, offering unparalleled customization for various applications. Its success in any given project depends heavily on the expertise, authoritativeness, and trustworthiness of its manufacturer. By choosing experienced and credible suppliers, businesses can harness the full potential of woven wire mesh, confident in the knowledge that they are supported by leading experts in the field committed to delivering excellence and innovation.

Enhancing Authoritativeness in Wire Mesh Solutions When seeking custom woven wire mesh solutions, it is imperative to consult with manufacturers that possess not only technical expertise but also an authoritative presence in the industry. Experienced manufacturers bring a wealth of knowledge that includes understanding the environmental factors affecting material choice, recognizing the nuances of various weaving techniques, and providing insights into potential applications and innovations. An authoritative manufacturer prioritizes quality assurance, conducting rigorous testing to adhere to international standards and certifications. This commitment to quality builds trust, assuring clients that their investment will yield a reliable and effective product. Manufacturers that invest in research and development also stay at the forefront of innovation, continually enhancing the capabilities of woven wire mesh to meet evolving industry challenges. Building Trust and Credibility Trust in custom woven wire mesh solutions extends beyond product quality—it encompasses the entire customer experience. Reputable suppliers provide comprehensive support, from initial consultation and design customization to final production and installation guidance. This holistic approach ensures that clients receive precisely what they need, backed by expert recommendations and support. Furthermore, reputable companies often offer sustainable production practices, enhancing their credibility by reducing environmental impact. By choosing suppliers that prioritize sustainability, clients can align their purchases with broader corporate responsibility goals, thereby adding value to their own brand reputation. In conclusion, custom woven wire mesh represents a synergy of art and engineering, offering unparalleled customization for various applications. Its success in any given project depends heavily on the expertise, authoritativeness, and trustworthiness of its manufacturer. By choosing experienced and credible suppliers, businesses can harness the full potential of woven wire mesh, confident in the knowledge that they are supported by leading experts in the field committed to delivering excellence and innovation.

Next:

Latest news

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025