-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ඔක්. . 06, 2024 03:36 Back to list

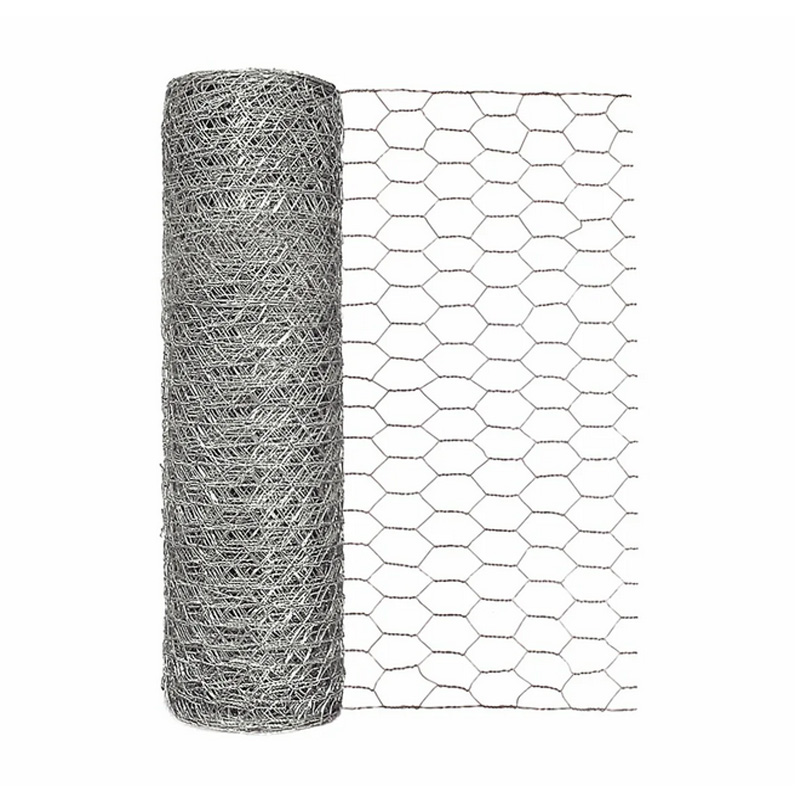

electro galvanized wire

Understanding Electro-Galvanized Wire Properties and Applications

Electro-galvanized wire is a type of wire that has been coated with a layer of zinc through an electrochemical process. This method of galvanization is highly regarded for its ability to provide good corrosion resistance while maintaining flexibility and ductility in the wire. Electro-galvanized wire is widely used in various industries, including construction, fencing, automotive, and agriculture, owing to its unique properties and benefits.

The Electro-Galvanization Process

Electro-galvanization involves immersing the wire in a solution containing zinc salts and applying an electric current. This setup encourages the deposition of zinc onto the wire surface. The thickness of the zinc layer can be controlled by adjusting the concentration of zinc in the solution, the voltage applied, and the duration of the electrical current. Typical thicknesses range from 5 to 20 microns.

The electro-galvanization process is preferred for its uniform coating and ability to provide a smooth finish. Unlike hot-dip galvanization, which involves dipping the wire into molten zinc, electro-galvanized wire exhibits less spattering and allows for precise control over the coating thickness. This smooth surface not only enhances the wire's appearance but also reduces the likelihood of surface imperfections.

Properties of Electro-Galvanized Wire

One of the primary advantages of electro-galvanized wire is its exceptional corrosion resistance. The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rusting. While not as robust as hot-dip galvanized wire, the electro-galvanized layer provides adequate protection for many applications, particularly in less aggressive environments.

Additionally, electro-galvanized wire retains high tensile strength, which is essential for many structural applications. Its flexibility and ductility make it easy to work with, allowing it to be bent or shaped without cracking. Electro-galvanized wire is also lightweight, making it easy to transport and install, particularly in large-scale projects.

Applications of Electro-Galvanized Wire

electro galvanized wire

Due to its properties, electro-galvanized wire finds applications in various fields

1. Construction Electro-galvanized wire is often used in reinforcing concrete, wire mesh, and ties. It helps to strengthen structures while providing rust resistance.

2. Fencing Many fencing products, such as chain link fences and barbed wire, utilize electro-galvanized wire due to its corrosion resistance, making it ideal for outdoor environments.

3. Automotive Industry Electro-galvanized wire is used in automotive components, such as springs and cables, where resistance to corrosion and wear is critical.

4. Agriculture In agriculture, electro-galvanized wire is employed in the construction of trellises and fencing for livestock, providing a durable solution that can withstand outdoor elements.

5. Electronics Manufacturing Due to its conductivity and corrosion resistance, electro-galvanized wire is used in various electronic components and applications.

Conclusion

Electro-galvanized wire serves as a reliable solution in numerous industries, offering an excellent balance of corrosion resistance, tensile strength, and flexibility. Its ability to be customized through the electro-galvanization process allows manufacturers to meet specific needs for various applications. As industries continue to focus on durable and cost-effective materials, the popularity of electro-galvanized wire is likely to grow, making it an essential component in modern manufacturing and construction practices. Whether in building infrastructures, supporting agricultural operations, or creating innovative automotive parts, the versatility of electro-galvanized wire undoubtedly enhances both functionality and longevity in products that require steel wire.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025