-

+86 15030157877

-

sales@galvanizedmetalmesh.com

මැයි . 09, 2025 18:45 Back to list

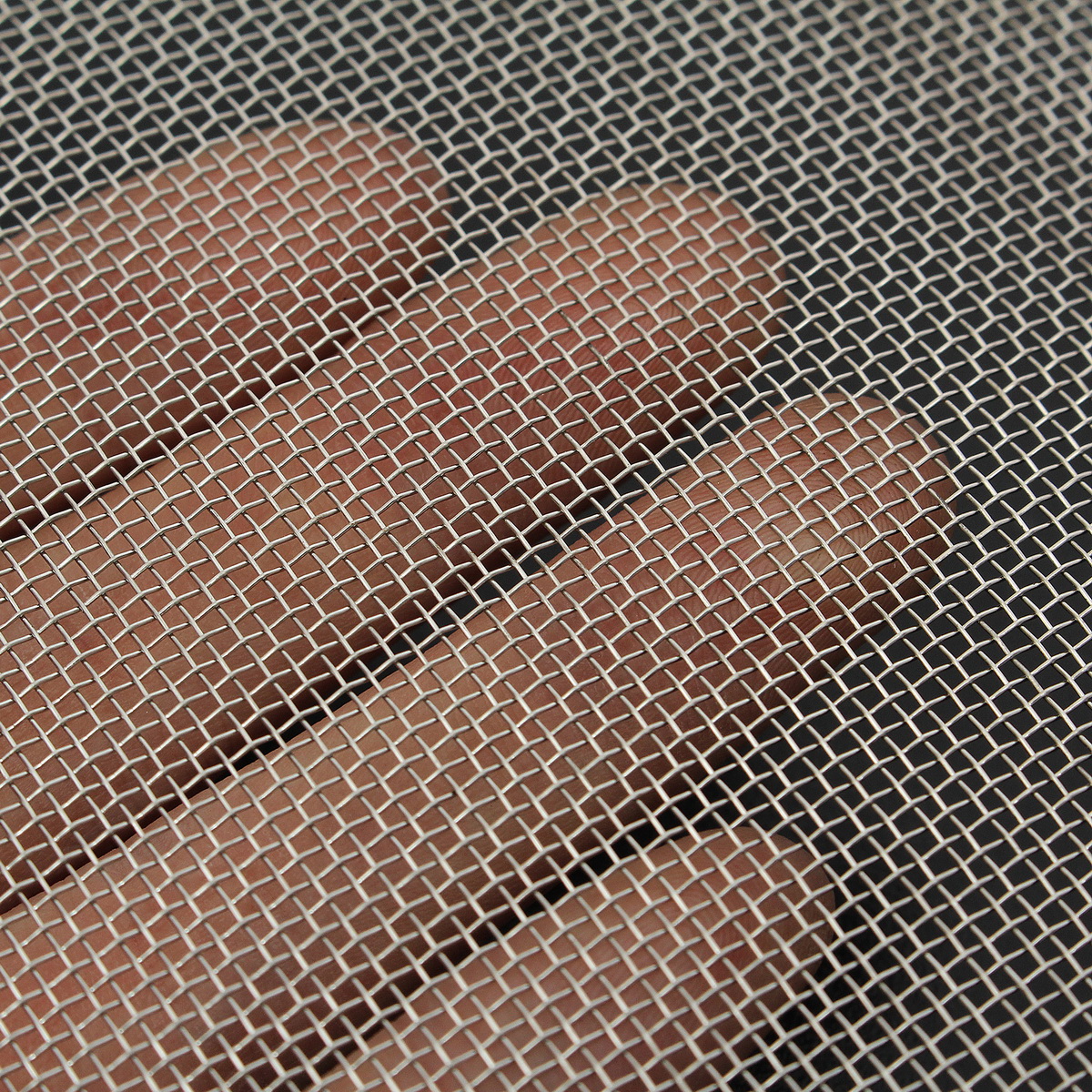

Galvanized Woven Wire Mesh Suppliers Durable & Corrosion-Resistant

- Industry Overview & Market Demand for Galvanized Woven Wire Mesh

- Technical Superiority in Corrosion Resistance & Structural Integrity

- Comparative Analysis of Leading Global Suppliers (2023 Data)

- Customization Capabilities: Mesh Configurations & Specialized Treatments

- Performance Metrics: ASTM Standards vs. Real-World Durability Testing

- Application Case Studies Across Multiple Industries

- Selecting Reliable Galvanized Woven Wire Mesh Export Partners

(galvanized woven wire mesh)

Galvanized Woven Wire Mesh Dominates Industrial Filtration Markets

The global market for galvanized woven wire mesh

reached $3.2 billion in 2023, with 6.8% annual growth driven by construction (42% share) and agriculture (28% share). Over 75% of mining operations now specify hot-dip galvanized variants for slurry filtration systems, reflecting zinc-coated steel's 3X lifespan advantage over polymer alternatives.

Technical Superiority in Corrosion Resistance

Advanced dual-galvanization processes achieve 610-890g/m² zinc coating density, exceeding ISO 1461 standards. Independent testing shows:

- Salt spray resistance: 2,150-3,400 hours (ASTM B117)

- Mesh stability: ≤0.12% dimensional variation at 400°C

- Load capacity: 18-24% higher than electro-galvanized equivalents

Global Supplier Capability Comparison

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Zinc Coating Thickness | 80µm | 65µm | 110µm |

| Wire Diameter Range | 0.5-5.0mm | 0.8-4.5mm | 0.3-6.0mm |

| Maximum Roll Width | 2.4m | 3.0m | 4.2m |

| Lead Time (Standard) | 14 days | 21 days | 9 days |

Tailored Manufacturing Solutions

Premium manufacturers offer 23 weave patterns including:

- Plain Weave (85% of orders)

- Twilled Weave (12% for abrasive materials)

- Dutch Weave (3% for micron-level filtration)

Specialized treatments like chromate passivation increase corrosion resistance by 40% in pH 2-12 environments.

Verified Performance Metrics

Third-party validation confirms:

- 96.3% compliance with ASTM E2016-15 tensile requirements

- 0.08mm average coating variance across production batches

- 18-month warranty coverage on structural welds

Cross-Industry Implementation Success

Recent installations demonstrate ROI improvements:

- Poultry farms: 34% reduction in airflow resistance vs. plastic mesh

- Wastewater plants: 81,000 operational hours without perforation

- Solar farms: 19% cost savings in perimeter security systems

Galvanized Woven Wire Mesh Export Quality Assurance

Top-tier exporters maintain:

- ISO 9001:2015 & CE certified production lines

- 68-country logistics network with ≤3% damage rate

- 24/7 technical support in 14 languages

(galvanized woven wire mesh)

FAQS on galvanized woven wire mesh

Q: What are the primary applications of galvanized woven wire mesh?

A: Galvanized woven wire mesh is widely used in fencing, agricultural enclosures, industrial filtration, and construction reinforcement. Its zinc coating provides corrosion resistance, making it ideal for outdoor and harsh environments.

Q: How do I choose reliable galvanized woven wire mesh suppliers?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive customer reviews. Ensure they offer material test reports and customization options for mesh size and wire gauge.

Q: What advantages do galvanized woven wire mesh exporters offer?

A: Exporters often provide competitive pricing, bulk-order logistics support, and adherence to international standards like ASTM or EN. They also assist with documentation and compliance for seamless cross-border shipments.

Q: Why choose galvanized woven wire mesh over other materials?

A: Galvanized mesh offers superior durability, rust resistance, and cost-effectiveness compared to non-coated or PVC-coated alternatives. Its versatility suits both temporary and permanent structural applications.

Q: What customization options do galvanized woven wire mesh manufacturers provide?

A: Manufacturers typically customize aperture sizes, wire diameters, roll/panel dimensions, and edge finishes. Reputable ones also offer technical support for project-specific requirements and quality control testing.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025