-

+86 15030157877

-

sales@galvanizedmetalmesh.com

දෙසැ. . 12, 2024 21:54 Back to list

Galvanized Square Woven Wire Mesh Manufacturing Facility Production Overview

The Excellence of Galvanized Square Woven Wire Mesh Production

In the realm of industrial materials, galvanized square woven wire mesh stands as a versatile and vital component used across various applications, from construction to agriculture and beyond. Its reliable strength, durability, and corrosion resistance make it an essential product in numerous sectors. In this article, we will delve into the characteristics, manufacturing processes, and the significance of galvanized square woven wire mesh, particularly focusing on the operations of a specialized factory dedicated to its production.

Understanding Galvanized Square Woven Wire Mesh

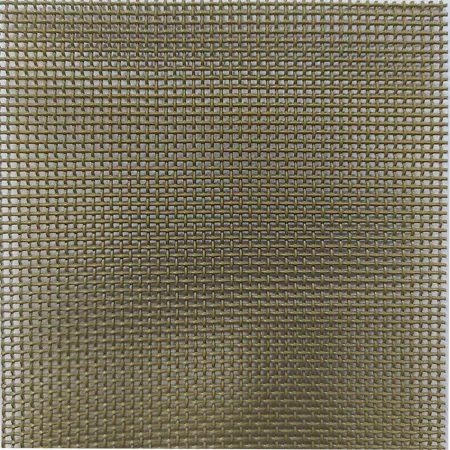

Galvanized square woven wire mesh is made from high-quality steel wire that is coated with a layer of zinc through a process known as galvanization. This coating not only enhances the wire's resistance to rust and corrosion but also prolongs its lifespan significantly. The structure consists of a square mesh configuration, which is woven into a grid pattern. The size of the openings can vary according to specific user requirements, providing a customizable solution for fencing, filtering, support, and ventilation.

Production Process at the Factory

The production of galvanized square woven wire mesh involves several critical steps, each requiring meticulous attention to detail. First and foremost, the factory sources high-quality steel wire, which is essential for ensuring the final product's strength and reliability. The wire is then drawn to the desired thickness using sophisticated machinery, which allows for precise control over the material properties.

Once the wire is prepared, the next step involves the weaving process. Advanced weaving machines are utilized to create the square mesh, ensuring uniformity and consistent quality throughout the entire batch. These machines can operate at high speeds, significantly increasing production efficiency without compromising the integrity of the final product.

galvanized square woven wire mesh factory

After weaving, the mesh is subjected to the galvanization process. This typically involves either electro-galvanization or hot-dip galvanization. In electro-galvanization, the wire is coated with zinc using an electrolytic process, while hot-dip galvanization involves immersing the woven mesh in molten zinc. Both methods produce a highly durable surface that protects against corrosion and environmental wear.

Once the galvanization is complete, the mesh undergoes rigorous quality control checks. This stage is crucial for upholding industry standards and client expectations. Testing for strength, corrosion resistance, and overall appearance ensures that each roll of wire mesh meets the specified requirements before it is shipped out to customers.

Applications and Importance

The applications of galvanized square woven wire mesh are extensive and diverse. In construction, it is commonly used for reinforcement in concrete structures and as protective barriers. In agriculture, it serves as fencing to safeguard livestock and crops while allowing for adequate airflow and sunlight. Additionally, it plays a significant role in industries such as mining, where it is used for screening and filtration purposes.

The importance of having a dedicated factory for the production of galvanized square woven wire mesh cannot be understated. Factories equipped with modern technology not only ensure the consistent production of high-quality mesh but also foster innovation in material science and engineering. They contribute to the local economy by providing jobs and supporting other ancillary industries.

Conclusion

In summary, the galvanized square woven wire mesh factory embodies the intersection of skilled craftsmanship and advanced technology. By focusing on quality and reliability, these factories are integral to supplying the growing demand for this essential industrial material. Through continuous improvements and innovations, they remain at the forefront of manufacturing, contributing to various sectors and enhancing the quality of everyday life. Whether for construction, agriculture, or industrial applications, the significance of galvanized square woven wire mesh continues to be pivotal in meeting modern-day demands.

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025