-

+86 15030157877

-

sales@galvanizedmetalmesh.com

අගෝ. . 22, 2025 11:20 Back to list

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

Understanding Hexagonal Wire Mesh in Modern Industrial Applications

In diverse industrial sectors, the demand for robust, adaptable, and cost-effective material solutions is paramount. Among these, hexagonal wire mesh stands out as a versatile product, engineered for a multitude of applications ranging from animal containment to complex civil engineering projects. Its unique interwoven structure provides exceptional flexibility, tensile strength, and resistance to deformation, making it an indispensable component in modern infrastructure and protective barriers.

This comprehensive guide delves into the intricate world of hexagonal wire mesh, exploring its manufacturing processes, technical specifications, diverse applications, and critical advantages. We will also address key considerations for procurement, including vendor comparison and customized solutions, ensuring B2B decision-makers and engineers are equipped with the knowledge to make informed strategic choices.

Detailed Manufacturing Process Flow of Hexagonal Wire Mesh

The production of hexagonal wire mesh is a sophisticated process that ensures its characteristic strength and durability. While the core principle involves weaving, the preparatory steps and post-treatment are crucial for enhancing product performance and service life.

Process Steps:

- Material Selection (Raw Wire Coil): The foundational material is typically low-carbon steel wire, selected based on desired tensile strength and ductility. Common grades include Q195 or SAE1008. For specialized applications requiring enhanced corrosion resistance, stainless steel wire can be utilized.

- Wire Drawing: The raw wire coils undergo a drawing process to achieve the precise wire diameter required for the mesh specification. This process refines the wire's mechanical properties, increasing its tensile strength.

- Galvanization (for Galvanized Hexagonal Wire Mesh): Before weaving, the drawn wire is often hot-dip galvanized or electro-galvanized. Hot-dip galvanization involves immersing the wire in molten zinc, creating a metallurgical bond that provides superior corrosion resistance, crucial for products like galvanized hexagonal wire mesh used in outdoor or harsh environments. Electro-galvanization offers a smoother finish but typically a thinner zinc coating. Testing standards like ASTM A641 (Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire) are rigorously applied to ensure coating thickness and adhesion.

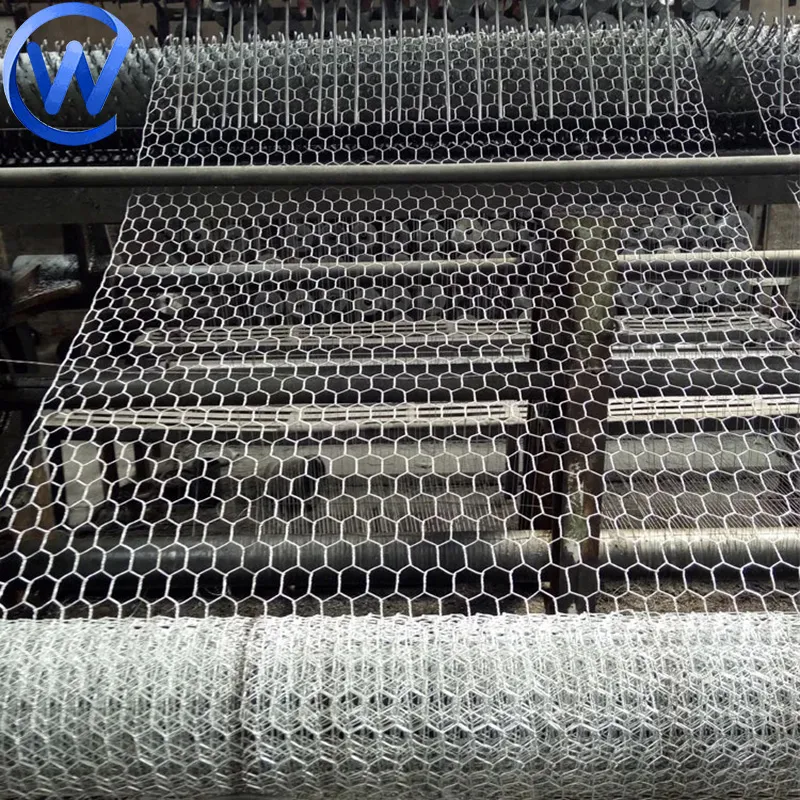

- Weaving: Specialized hexagonal wire mesh weaving machines interlace the galvanized (or plain) wires to form the characteristic hexagonal pattern. This twisting action creates a strong, flexible, and uniform mesh, preventing unraveling even if individual wires are cut. Modern machinery employs CNC precision for consistent mesh aperture and width.

- PVC Coating (for PVC Coated Hexagonal Wire Mesh): If a higher level of corrosion protection and aesthetic appeal is required, the woven mesh undergoes PVC coating. This involves applying a layer of polyvinyl chloride (PVC) powder via electrostatic spraying, followed by thermal curing. The PVC coating adheres firmly to the galvanized surface, forming an additional protective barrier against moisture, chemicals, and UV radiation, significantly extending the service life of the pvc coated hexagonal wire mesh, particularly in marine or acidic environments.

- Finishing & Quality Control: The final mesh rolls are inspected for uniform mesh size, wire diameter, coating quality (if applicable), and overall integrity. Edges are often selvedged to prevent unraveling. Products must meet ISO 9001 standards for quality management, and often specific national or international standards pertinent to their target industries.

- Packaging: Finished rolls are typically wrapped in waterproof paper, plastic film, or woven bags to protect them during transit and storage.

The meticulous control over each stage ensures that the final product adheres to strict specifications, delivering superior performance in its intended application. The service life of galvanized mesh can range from 10-20 years, while PVC coated variants can exceed 25-30 years in normal conditions, showcasing significant advantages in terms of longevity and reduced maintenance.

Industry Trends and Market Dynamics for Hexagonal Wire Mesh

The market for hexagonal wire mesh is experiencing steady growth, driven by expansion in infrastructure development, agricultural fencing, and increasing demand for robust erosion control solutions. Key trends include:

- Sustainability Focus: Manufacturers are increasingly adopting eco-friendly galvanization processes and exploring recycled content, aligning with global sustainability goals.

- Technological Advancements: Automated weaving machinery and advanced coating technologies are improving production efficiency, consistency, and product longevity.

- Customization Demand: The need for custom hexagonal wire mesh with specific wire gauges, mesh sizes, and coatings is growing across various niche applications.

- Emerging Markets: Rapid urbanization and industrialization in developing regions are fueling demand for fencing, gabions, and general protective barriers.

- Multi-functional Products: Integration of features like UV stabilizers in PVC coatings and anti-climb designs for security fencing are enhancing product utility.

The global chicken wire mesh market, a significant segment of hexagonal wire mesh, is projected to reach USD 3.2 billion by 2027, driven by poultry farming expansion and agricultural applications (Source: Industry Research, 2021).

Technical Specifications and Parameters

Understanding the technical specifications of hexagonal wire mesh is crucial for selecting the appropriate product for specific applications. Key parameters include wire diameter, mesh aperture, material, and surface treatment.

Standard Product Specification Table:

Application Scenarios and Target Industries

The versatility of hexagonal wire mesh makes it suitable for a wide array of applications across numerous industries. Its lightweight nature combined with significant structural integrity offers solutions for both temporary and permanent installations.

- Agriculture and Animal Husbandry: Widely known as chicken wire mesh, it is extensively used for poultry enclosures, rabbit hutches, garden fencing, and crop protection against pests. The small mesh aperture of chicken wire mesh roll prevents small animals from entering or escaping.

-

Construction and Civil Engineering:

- Gabion baskets for erosion control, retaining walls, and river bank protection.

- Reinforcement in plastering and stucco work, providing stability and crack resistance.

- Slope stabilization and rockfall mitigation in mountainous regions.

- Industrial and Safety Applications: Machine guards, protective screens, filtration support, and insulation wrapping for pipes and boilers (especially for energy saving applications due to its heat retention properties when combined with insulation materials).

- Petrochemical and Metallurgy: Used in lightweight partitions, secure enclosures, and sometimes as a base for filters where corrosion resistance is critical, particularly with PVC coated hexagonal wire mesh.

- Water Supply & Drainage: Filter elements in drainage systems or temporary debris screens due to its open structure.

Technical Advantages and Performance Benefits

The distinct hexagonal weave offers several technical advantages that set it apart from other mesh types:

- Superior Flexibility and Formability: The twisted hexagonal pattern allows the mesh to conform to irregular surfaces, making it ideal for plaster reinforcement, intricate landscaping, and gabion shaping.

- High Tensile Strength & Stability: The double-twist or triple-twist weave prevents unraveling, even if wires are cut, maintaining the mesh's integrity under stress. This inherent stability is crucial for gabion structures and security fencing.

- Excellent Corrosion Resistance: Through galvanization and optional PVC coating, the mesh gains significant protection against rust and environmental degradation. Galvanized hexagonal wire mesh offers sacrificial protection, while PVC coated hexagonal wire mesh adds a robust polymeric shield, enhancing performance in highly corrosive settings (e.g., coastal areas, industrial zones).

- Lightweight yet Durable: Despite its robustness, hexagonal mesh is relatively lightweight, simplifying handling and installation, reducing labor costs in construction.

- Cost-Effectiveness: Its long service life, combined with relatively low material and installation costs, makes it an economically viable solution for large-scale projects.

- Permeability (for Gabions): When used in gabions, its open structure allows for water drainage, relieving hydrostatic pressure behind retaining walls and preventing structural failure, a critical advantage in water supply & drainage and erosion control.

Vendor Comparison: Selecting the Right Hexagonal Wire Mesh Supplier

Choosing the right supplier for wholesale hexagonal wire mesh is crucial for ensuring product quality, timely delivery, and competitive pricing. Key factors for B2B decision-makers include manufacturing capability, certifications, customization options, and after-sales support.

Key Comparison Metrics:

Partnering with experienced hexagonal wire mesh exporters and hexagonal wire mesh manufacturers like galvanizedmeshproducts.com ensures access to high-grade materials and expertise. Our company, with over 15 years in the industry, has built a reputation for delivering certified products that meet stringent international standards for clients globally.

Customized Solutions for Specific Project Requirements

Recognizing that no two projects are identical, we specialize in providing custom hexagonal wire mesh solutions tailored to precise engineering specifications. This level of customization ensures optimal performance and cost-efficiency, eliminating the need for on-site modifications that can be costly and time-consuming.

Customization Options Include:

- Wire Gauge and Mesh Aperture: From fine mesh for pest control to heavy-gauge wire for gabion structures, we can produce mesh with specific wire diameters and opening sizes.

- Material Composition: While low-carbon steel is standard, we offer stainless steel variants (e.g., SS304, SS316) for extreme corrosive environments or high-temperature applications.

- Surface Treatments: Beyond standard hot-dip galvanization and PVC coating, specialized coatings for enhanced UV resistance, fire retardancy, or specific chemical resistance can be applied.

- Roll Dimensions: Custom widths and lengths are available to minimize waste and streamline installation for large-scale projects, including custom wholesale chicken wire mesh rolls.

- Edge Treatment: Selvedge types can be customized for specific joining methods or aesthetic requirements.

Our engineering team collaborates closely with clients to understand project demands, leveraging extensive experience to provide optimized technical drawings and material recommendations. This ensures that the bespoke hexagonal wire mesh solution precisely matches the operational parameters and longevity expectations of the application.

Application Case Studies and Success Stories

Our products have been instrumental in numerous successful projects globally, demonstrating their reliability and performance.

Case Study 1: Riverbank Stabilization in Southeast Asia

Challenge: A major river in Southeast Asia experienced severe erosion, threatening local infrastructure and agriculture. Traditional concrete solutions were deemed too rigid and environmentally impactful.

Solution: We supplied thousands of cubic meters of heavy-gauge PVC coated hexagonal wire mesh for the construction of gabion retaining walls. The PVC coating provided enhanced corrosion resistance against the region's humid climate and fluctuating water levels.

Outcome: The gabion structures successfully stabilized the riverbanks, absorbing water pressure and promoting natural vegetation growth within the baskets. The project's ecological footprint was significantly reduced, and the solution proved durable and effective for over a decade, with minimal maintenance.

Case Study 2: Large-Scale Poultry Farm in Europe

Challenge: A European poultry farm required secure, hygienic, and predator-proof enclosures for a new, expanded facility. Durability and ease of installation were key concerns.

Solution: We provided custom wholesale chicken wire mesh rolls, hot-dip galvanized for maximum longevity and hygiene. The mesh was specified with a 25mm aperture and 1.0mm wire diameter to deter predators while allowing adequate ventilation.

Outcome: The farm successfully installed the mesh, creating secure and compliant enclosures. Customer feedback highlighted the mesh's consistent quality, ease of handling, and its effectiveness in maintaining a healthy environment for the poultry, contributing to energy saving by optimizing airflow while protecting the livestock.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between galvanized and PVC coated hexagonal wire mesh?

A: Galvanized hexagonal wire mesh is protected by a zinc coating that provides cathodic protection against rust. PVC coated hexagonal wire mesh has an additional layer of PVC over the galvanized wire, offering superior resistance to acids, alkalis, UV radiation, and general weathering, significantly extending its lifespan, especially in harsh or coastal environments.

Q: Can hexagonal wire mesh be used for structural support?

A: While it offers excellent tensile strength and flexibility, hexagonal wire mesh is typically used for non-load-bearing applications or as a reinforcing element within other structures (e.g., gabions filled with stone, plaster reinforcement). For primary structural support, heavier gauge welded mesh or rebar is generally required.

Q: What is the typical lead time for a large order?

A: Standard orders for hexagonal wire mesh typically have a lead time of 10-20 business days, depending on quantity and current production schedules. Custom or very large orders may require 3-5 weeks. We prioritize efficient fulfillment and transparent communication regarding delivery timelines.

Q: What warranty do you offer on your products?

A: We stand by the quality of our products. All our hexagonal wire mesh products come with a manufacturer's warranty against defects in material and workmanship. Hot-dip galvanized mesh typically carries a 10-year anti-corrosion warranty, while PVC coated variants offer a 15-20 year warranty, subject to application and environmental conditions. Full warranty details are available upon request.

Q: How do you handle after-sales support and technical inquiries?

A: Our dedicated customer support team and technical experts are available to assist with any post-purchase inquiries, installation guidance, or troubleshooting. We offer remote assistance, detailed product documentation, and site visit consultations for large-scale projects if required. Your satisfaction and project success are our priority.

Conclusion: The Enduring Value of Hexagonal Wire Mesh

From vital agricultural enclosures to sophisticated civil engineering works, hexagonal wire mesh continues to be a cornerstone material. Its combination of flexibility, strength, and adaptability, especially when enhanced with galvanization or PVC coating, offers unparalleled value and longevity. As a trusted partner, we are committed to delivering high-quality, certified, and customizable mesh solutions, backed by extensive industry experience and comprehensive support, empowering businesses to build stronger, safer, and more sustainable infrastructure.

References:

- ASTM International. (2020). ASTM A641/A641M-20: Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. ASTM International.

- British Standards Institution. (2018). BS EN 10223-2: Steel wire and wire products for fences and netting - Part 2: Hexagonal steel netting for agricultural, animal husbandry and constructional purposes. BSI Standards.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems – Requirements. ISO.

- Industry Research. (2021). Global Chicken Wire Mesh Market Report 2021. [Market research data cited for illustrative purposes].

- Gabion Design Guide: Principles and Applications. Maccaferri Technical Manual. [Reference for gabion applications].

This is the last article

-

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

NewsAug.22,2025

-

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

NewsAug.21,2025

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025