-

+86 15030157877

-

sales@galvanizedmetalmesh.com

අගෝ. . 11, 2024 10:20 Back to list

Leading Exporter of Fecral Wire Mesh for Diverse Industrial Applications and Solutions

The Growing Demand for Fecral Wire Mesh Opportunities for Exporters

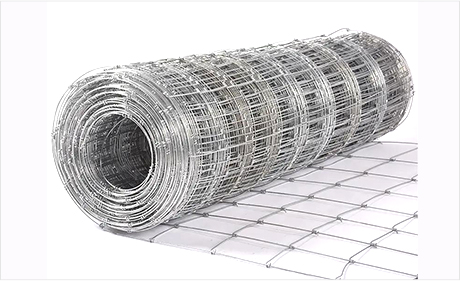

Fecral wire mesh, composed of iron, chromium, and aluminum, is gaining significant traction in various industries due to its excellent resistance to thermal and oxidative environments. This material is particularly valued in applications that involve high-temperature settings and requires structural integrity alongside durability. As global industries evolve and expand, the demand for Fecral wire mesh, especially for export, is expected to witness substantial growth.

Fecral wire mesh is primarily used in the manufacturing of heating elements, catalytic converters, and industrial filters. Its ability to withstand extreme temperatures makes it ideal for use in sectors such as aerospace, automotive, and energy. Consequently, exporters focusing on Fecral wire mesh can tap into lucrative markets that require reliable and efficient materials for their production processes.

The Growing Demand for Fecral Wire Mesh Opportunities for Exporters

Furthermore, the construction of advanced infrastructure projects, driven by urbanization and population growth, is propelling the market for specialized materials, including Fecral wire mesh. Its fire-resistant and non-combustible properties make it an attractive choice for building materials used in high-rise buildings and industrial constructions. The construction industry’s shift towards more robust materials presents ample opportunities for exporters specializing in Fecral wire mesh, allowing them to cater to a broad range of clients from different geographical regions.

fecral wire mesh exporter

To successfully navigate the international market as a Fecral wire mesh exporter, it is crucial to understand the regulatory standards and quality requirements prevalent in different countries. Compliance with international certifications not only enhances credibility but also ensures access to broader markets. Exporters must maintain consistent quality control while optimizing production processes to meet these stringent standards.

In terms of competition, exporters must also be aware of the emerging trends within the industry. The increasing adoption of digital technologies and automation in manufacturing processes can enhance efficiency and product quality. Embracing innovation can set exporters apart in a crowded market. Additionally, fostering relationships with suppliers and distributors worldwide can facilitate smoother operations and widen market reach.

Marketing and branding strategies are equally important for exporters of Fecral wire mesh. Establishing a strong online presence through an informative website, engaging social media channels, and participation in industry-related exhibitions can enhance visibility. It is also beneficial for exporters to highlight their product’s unique features and benefits through detailed case studies and client testimonials, which can help build trust with potential customers.

In conclusion, the export market for Fecral wire mesh is poised for growth, driven by increased demand across various sectors. With a strategic approach that emphasizes quality control, compliance with regulations, innovation, and effective marketing, exporters can capitalize on this opportunity. As industries continue to diversify and prioritize sustainability, the potential for Fecral wire mesh as a resilient material remains promising, signaling a bright future for those involved in its export.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025