-

+86 15030157877

-

sales@galvanizedmetalmesh.com

දෙසැ. . 02, 2024 01:47 Back to list

Stainless Steel Welded Wire Mesh Panel Production Facility Overview

The Significance of Stainless Steel Welded Wire Mesh Panel Factories

In the realm of industrial manufacturing and construction, the need for durable and reliable materials is paramount. One such product that has gained tremendous popularity is stainless steel welded wire mesh panels. This article delves into the significance of factories producing these essential components, exploring their benefits, applications, and the manufacturing processes involved.

What are Stainless Steel Welded Wire Mesh Panels?

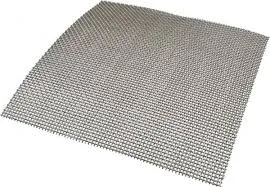

Stainless steel welded wire mesh panels are constructed from stainless steel wires that are welded together at their intersection points, forming a grid-like structure. The use of stainless steel provides a high level of resistance against corrosion, rust, and other forms of deterioration, making these panels suitable for various environments, especially those exposed to moisture or harsh chemicals.

Key Benefits of Stainless Steel Welded Wire Mesh Panels

1. Durability The foremost advantage of stainless steel welded wire mesh is its incredible strength and durability. Unlike other materials, stainless steel can withstand extreme conditions, making it an ideal choice for both indoor and outdoor applications.

2. Corrosion Resistance Stainless steel is well-known for its ability to resist rust and corrosion. This characteristic is particularly advantageous in industries such as agriculture, food processing, and pharmaceuticals, where hygiene and cleanliness are critical.

3. Versatility Welded wire mesh panels are incredibly versatile in their applications. They can be used for fencing, supporting structures, filters, and even art installations. This flexibility allows manufacturers to cater to a wide range of industries, including construction, agriculture, and transportation.

4. Cost-Effectiveness While the initial investment in stainless steel may be higher than other materials, the long-term savings associated with durability and low maintenance contribute to its cost-effectiveness. Businesses can save significantly over time by reducing the need for frequent replacements.

5. Aesthetic Appeal With a sleek and modern appearance, stainless steel welded wire mesh panels can also enhance the visual appeal of structures. They are often used in architectural applications where both function and aesthetics are prioritized.

stainless steel welded wire mesh panel factory

The Manufacturing Process

The production of stainless steel welded wire mesh panels involves several key steps

1. Material Selection The process begins with the selection of high-quality stainless steel wires, which come in various gauges and finishes. The choice of material is crucial as it affects the overall performance of the final product.

2. Wire Drawing The selected stainless steel rods are drawn through dies to achieve the desired diameter. This process ensures uniformity and the right mechanical properties necessary for welding.

3. Welding The drawn wires are arranged in a grid pattern and welded together at their intersections. This is typically done using automated welding machines, which ensure precision and consistency in the weld joints.

4. Post-Welding Treatment After welding, the panels undergo treatment processes such as cleaning, passivation, and sometimes even polishing to enhance their properties. These treatments help improve corrosion resistance and aesthetic quality.

5. Cutting and Packaging Finally, the welded wire mesh panels are cut to specified dimensions and packaged for shipment. Factories often maintain strict quality control measures to ensure that every panel meets industry standards.

Conclusion

The role of stainless steel welded wire mesh panel factories is pivotal in supplying industries with a product that exemplifies strength, durability, and versatility. As construction and manufacturing sectors continue to evolve, the demand for high-quality materials like stainless steel welded wire mesh panels will undoubtedly rise. Consequently, these factories are not only contributing to building safer and more efficient structures but also paving the way for innovations in material applications across various industries. By understanding the benefits and processes involved, businesses can make informed decisions that enhance their operations and lending to a sustainable future.

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025