-

+86 15030157877

-

sales@galvanizedmetalmesh.com

දෙසැ. . 04, 2024 00:13 Back to list

Leading Manufacturers of Steel Grating for Industrial and Commercial Applications

Understanding Steel Grating Manufacturers A Comprehensive Overview

Steel grating is an essential component used across numerous industries, providing safe and reliable solutions for flooring, walkways, and various structural applications. The manufacturers of steel grating play a crucial role in producing these vital products, each with its unique characteristics and advantages. This article will explore the different aspects of steel grating manufacturers, including their manufacturing processes, product types, applications, and factors to consider when selecting a supplier.

The Manufacturing Process

Steel grating is typically manufactured through two primary methods welded and press-locked.

1. Welded Grating This is the most common type of grating, produced by welding together the load-bearing bars and cross bars. The process involves heating the metal until it is red-hot, followed by fusion under high pressure. This results in a robust and durable product appropriate for heavy-duty applications.

2. Press-Locked Grating This method involves interlocking the bars without welding. The load-bearing bars and the cross bars are pressed together, which eliminates the need for heat and reduces the risk of corrosion at the seams. This method is ideal for applications where a lightweight and corrosion-resistant grating is advantageous.

Both types of grating can be fabricated in various materials, thicknesses, and dimensions, offering versatility and customization to meet specific project requirements.

Types of Steel Grating

Steel grating manufacturers produce a variety of grating types, each designed for specific applications. The main types include

1. Heavy-duty Grating Suitable for industrial applications that demand high load-bearing capacity, such as heavy machinery access and industrial flooring.

3. Safety Grating Features additional slip-resistant coatings or surface patterns. These are particularly critical in environments prone to spills or where workers are at risk of slip-and-fall accidents.

4. Custom Grating Many manufacturers are capable of producing custom grating solutions tailored to unique requirements, including specific shapes, sizes, or materials.

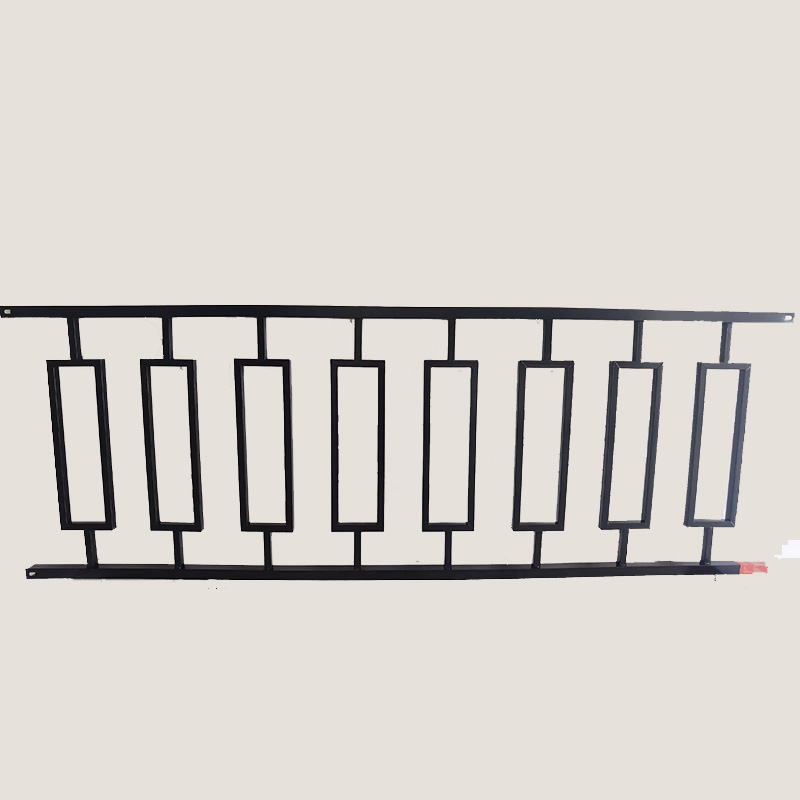

steel grating manufacturers

Applications of Steel Grating

Steel grating is widely used across various sectors, including

- Industrial Sector It is often found in factories, warehouses, and power plants where heavy machinery operates and robust flooring is necessary for safety and durability. - Commercial Sector In commercial buildings, steel grating is utilized as walkways, stairs, and platforms, providing access and visibility. - Municipal Projects Steel grating is commonly used in drainage systems and roadways to facilitate water runoff while providing structural support. - Transport Infrastructure Railways and airports utilize steel grating for pedestrian walkways, luggage handling areas, and access platforms.

Choosing the Right Manufacturer

When selecting a steel grating manufacturer, there are several factors to consider to ensure you receive a high-quality product that meets your needs

1. Reputation and Experience Look for manufacturers with a proven track record in the industry. Reading customer reviews and testimonials can provide insight into their reliability and product quality.

2. Quality Standards Ensure the manufacturer adheres to relevant industry standards and certifications, which can indicate the quality and safety of their products.

3. Customization Options Depending on your project requirements, consider manufacturers that offer custom fabrication services to match your specific dimensions and design needs.

4. Material Sourcing Investigate the materials used by the manufacturer and their sourcing practices. The quality of raw materials directly affects the performance and durability of the finished product.

5. Support and Service Opt for manufacturers that provide excellent customer service, including technical support, product warranties, and after-sales service. This can make a significant difference in your overall experience and satisfaction.

Conclusion

Steel grating manufacturers are an integral part of various industries, offering essential products that contribute to safety and efficiency. By understanding the manufacturing processes, types of grating available, and factors to consider when choosing a manufacturer, you can make informed decisions that ensure the success of your projects. With the right provider, steel grating can provide a reliable long-term solution for your construction and industrial needs.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025