-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ජන. . 09, 2025 11:31 Back to list

welded wire mesh

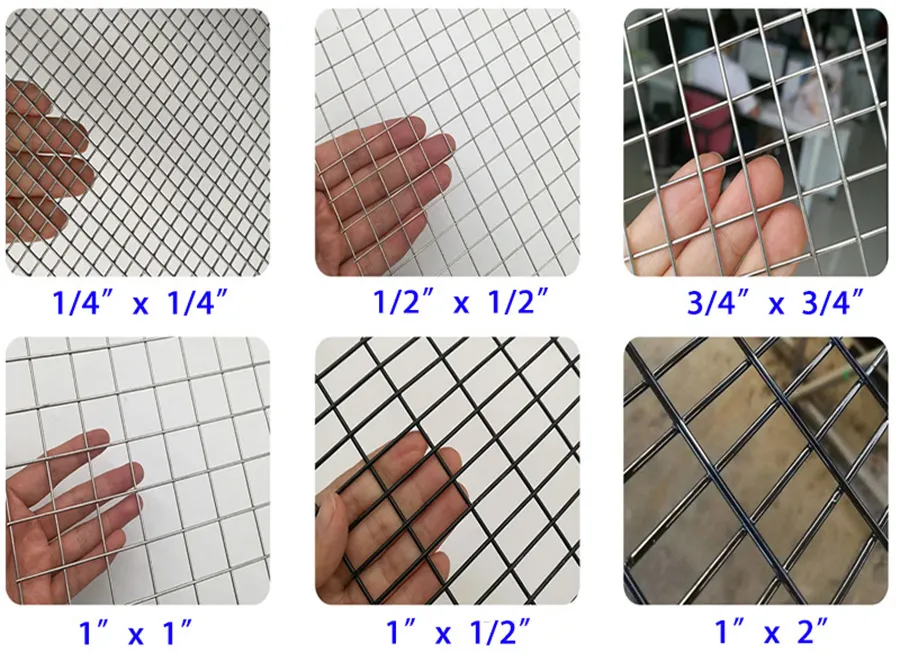

Welded wire mesh is an indispensable component in modern construction and agricultural industries. As an engineered grid made from stainless steel or galvanized iron, its applications range from reinforcing concrete structures to creating secure enclosures for livestock. Its versatile nature is matched only by its reliability, a vital characteristic forged through scientific innovation and rigorous testing.

From an expertise standpoint, the dimensional accuracy of welded wire mesh is paramount. Engineers and architects rely on stringent specifications to ensure seamless application. This precision is established through modern production lines that utilize computer-aided designs to dictate the dimensions and patterns of the mesh. Such sophisticated technology not only boosts production efficiency but also guarantees conformity to international standards, reinforcing the product's trustworthiness and authority in professional circles. Moreover, the environmental impact of welded wire mesh is an emerging area of focus. Leading suppliers are now committed to sustainable manufacturing practices, utilizing recycled materials and improving energy efficiency throughout the production process. This shift towards sustainability ensures that customers receive a product that meets both their practical needs and their ethical standards. Given the growing importance of eco-friendly practices, welded wire mesh stands out as an exemplary choice for environmentally conscious construction and farming projects. As a product with certified quality and a proven track record, welded wire mesh commands the trust of countless engineers, contractors, and agriculturists worldwide. It is backed by rigorous testing and compliance with industry standards, which underline its reliability and effectiveness. Whether used as reinforcement in concrete or as fencing material, the innovative design and superior strength of welded wire mesh continue to make it an essential material in diverse applications, cementing its status as a cornerstone in the fields it serves.

From an expertise standpoint, the dimensional accuracy of welded wire mesh is paramount. Engineers and architects rely on stringent specifications to ensure seamless application. This precision is established through modern production lines that utilize computer-aided designs to dictate the dimensions and patterns of the mesh. Such sophisticated technology not only boosts production efficiency but also guarantees conformity to international standards, reinforcing the product's trustworthiness and authority in professional circles. Moreover, the environmental impact of welded wire mesh is an emerging area of focus. Leading suppliers are now committed to sustainable manufacturing practices, utilizing recycled materials and improving energy efficiency throughout the production process. This shift towards sustainability ensures that customers receive a product that meets both their practical needs and their ethical standards. Given the growing importance of eco-friendly practices, welded wire mesh stands out as an exemplary choice for environmentally conscious construction and farming projects. As a product with certified quality and a proven track record, welded wire mesh commands the trust of countless engineers, contractors, and agriculturists worldwide. It is backed by rigorous testing and compliance with industry standards, which underline its reliability and effectiveness. Whether used as reinforcement in concrete or as fencing material, the innovative design and superior strength of welded wire mesh continue to make it an essential material in diverse applications, cementing its status as a cornerstone in the fields it serves.

Latest news

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025