-

+86 15030157877

-

sales@galvanizedmetalmesh.com

සැප්. . 02, 2025 09:39 ලැයිස්තුවට ආපසු

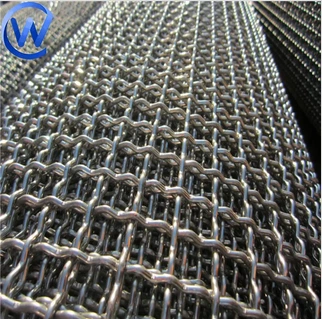

Wire Mesh Screens for Trommels and Scalpers

In the demanding worlds of mining, aggregate processing, recycling, and composting, efficiency and durability aren't just desirable – they're essential for profitability. At the heart of critical screening equipment like trommels and scalpers lies a component that dictates performance: wire mesh screens. For over two decades, HEBEI WEICHUN WIRE MESH TRADE CO., LTD. has been a cornerstone supplier in this vital industry. Founded in 1995 in Anping County, Hebei Province – China's renowned wire mesh hub – we've grown through an unwavering commitment to quality, reputation, and customer partnership. With over 20 years of manufacturing and exporting expertise, a turnover exceeding 200 million RMB, and a global clientele spanning India, Singapore, Mexico, Germany, the USA, UAE, and beyond, we understand the rigorous demands placed on screening media. Our advanced production facilities, staffed by skilled technicians and governed by scientific quality control, are dedicated to delivering robust, cost-effective wire mesh solutions that maximize uptime and productivity for wholesalers and large-scale operators worldwide. We recognize that your success hinges on reliable supply chains and high-performance components, making the choice of wire mesh screen a pivotal business decision.

The Indispensable Role of Wire Mesh in Trommel & Scalper Performance

Trommels (rotary screens) and scalpers (heavy-duty pre-screens) are the workhorses of material classification. Their primary function is to separate raw materials – ores, aggregates, demolition waste, topsoil, compost – into specific size fractions. The wire mesh screen is the critical interface where this separation physically occurs. Its aperture size determines the cut point, while its structural integrity ensures consistent performance under punishing loads, abrasion, and impact. Choosing subpar mesh leads to frequent failures: blinding (apertures clogging), pegging (particles wedging), accelerated wear, and catastrophic panel blowouts. These failures translate directly into costly downtime, lost production, increased labor for maintenance, and premature replacement expenses. High-quality woven wire mesh, specifically engineered for these applications, forms a resilient, precise filtering surface. It allows undersize material to pass efficiently while conveying oversize material along the screen deck for discharge. The mesh must maintain its precise opening dimensions despite constant vibration, heavy impacts from rocks or debris, and exposure to harsh environmental elements. Investing in premium wire mesh isn't just an equipment cost; it's an investment in operational continuity and bottom-line profitability for your customers.

Stainless Wire Mesh: The Superior Choice for Longevity and Corrosion Resistance

While various metals are used in screening, මල නොබැඳෙන කම්බි දැලක් stands out as the premier choice for trommels and scalpers, particularly in demanding or corrosive environments. Its dominance stems from unparalleled material properties:

Exceptional Corrosion Resistance: Grades like 304, 304L, 316, and 316L stainless steel contain chromium (and often nickel/molybdenum) that form a passive, self-repairing oxide layer. This makes them highly resistant to rust caused by moisture, acidic soils, salt spray in coastal operations, chemical leaching in recycling, or corrosive compounds in fertilizers and compost. Carbon steel meshes rust quickly, weakening wires and leading to premature failure.

Superior Strength & Wear Resistance: Stainless steel alloys offer high tensile strength and excellent resistance to abrasion from constant material flow. This translates directly into longer screen life, reducing the frequency of costly panel replacements and associated downtime.

High-Temperature Stability: Stainless wire mesh retains its strength and dimensional integrity at elevated temperatures encountered in processes like hot aggregate screening or certain recycling applications.

Hygienic & Non-Reactive: The non-porous surface resists material build-up and is easy to clean. It doesn't react with or contaminate processed materials, crucial in applications like food waste composting or sensitive mineral processing.

Long-Term Cost Efficiency: While the initial purchase price of මල නොබැඳෙන කම්බි දැලක් might be higher than alternatives, its dramatically extended service life and reduced maintenance needs result in a significantly lower total cost of ownership.

For wholesalers, offering මල නොබැඳෙන කම්බි දැලක් screens means providing your clients with a product that delivers maximum uptime, minimizes operational headaches, and offers the best return on investment, especially in harsh conditions.

Woven Wire Mesh: Precision and Versatility in Screening Media

The method of construction is as crucial as the material. Woven wire mesh is the gold standard for trommel and scalper screens due to its precision, strength, and adaptability. Unlike punched plate or perforated sheet, woven mesh offers:

Precise & Consistent Aperture Control: Wires are methodically interlaced on industrial looms, ensuring exact and uniform opening sizes critical for accurate particle separation. This precision is vital for product quality control.

High Open Area: Well-designed woven wire mesh patterns maximize the percentage of open space relative to the total screen area. High open area translates directly to higher screening efficiency and throughput capacity.

Structural Integrity & Stability: The weaving process locks wires firmly in place, creating a stable, rigid panel resistant to deformation under load. This stability maintains aperture accuracy throughout the screen's life.

Variety of Weaves for Specific Needs: Different weaving patterns offer distinct advantages:

Plain Weave: The most common, simple over-under pattern. Good general-purpose weave.

Twill Weave: Wires pass over and under two or more warp wires. Creates a sturdier mesh with better flow characteristics than plain weave for similar wire diameters. Resists blinding better.

Dutch Weave (Plain & Twilled): Features thicker warp wires and much finer weft wires woven tightly together. Creates a very smooth surface and extremely fine filtration capabilities, excellent for dewatering or fine material separation where blinding is a major concern.

Reverse Dutch Weave: Similar to Dutch weave but with the thick/thin wire positions reversed, offering different flow characteristics.

Five Heddle Weave: Complex pattern providing exceptional strength and stability for very heavy-duty scalping applications.

Lock Crimp & Intercrimp: Pre-crimped wires are woven so the crimps lock tightly at intersections. Provides maximum rigidity and resistance to movement under heavy impact loads, essential for scalping large, abrasive feed material.

Woven wire mesh provides the flexibility to tailor screen performance precisely to the application, whether it's scalping large rocks or finely classifying sand.

Optimizing Performance: Material, Weave, and Feature Synergy

Selecting the optimal trommel or scalper screen requires harmonizing the මල නොබැඳෙන කම්බි දැලක් grade, the woven wire mesh pattern, and specific engineered features to meet the unique demands of the application. Here’s a breakdown of key parameters and their impact:

Wire Mesh Screens for Trommels & Scalpers - Key Specifications

|

Parameter |

Options |

Impact on Performance |

|

Material (Stainless Steel Grade) |

302, 304, 304L, 316, 316L, 321, 430 |

Dictates corrosion resistance, strength, temperature tolerance, and cost. 304/304L (general purpose), 316/316L (high corrosion/acid), 430 (cost-effective, moderate corrosion). |

|

Weaving Type |

Plain Weave, Twill Weave, Dutch Plain Weave, Dutch Twill Weave, Reverse Dutch Weave, Five Heddle Weave, Lock Crimp, Inter Crimp |

Determines aperture precision, open area %, flow characteristics, resistance to blinding/pegging, and structural rigidity for impact resistance. |

|

Key Features |

Widely used filtration material; Resistance to acid/alkali; Cleaner/bright appearance; Excellent rust/corrosion resistance; Resistance to chemicals/harsh weather; High strength/Durable |

Core Benefits: Long service life, consistent screening accuracy, minimal maintenance, suitability for diverse harsh environments, reliable operation. |

Material Selection: Matching the grade to the environment is critical. 304/304L offers excellent all-around corrosion resistance for most aggregate, mining, and general recycling. 316/316L, with added molybdenum, is essential for high-chloride environments (coastal, salt-laden roads), acidic conditions (composting, chemical recycling), or exposure to seawater. 430 provides a more economical option with moderate corrosion resistance for less demanding applications. 321 offers enhanced high-temperature stability.

Weave Selection: For heavy scalping of large, abrasive material (e.g., primary scalpers in quarries), Lock Crimp or Inter Crimp weaves provide unmatched rigidity and impact resistance. Twill Weave is often ideal for standard trommel applications, balancing good flow, resistance to blinding, and durability. Dutch Weaves (Plain or Twill) are the solution for fine screening, dewatering, or sticky materials prone to blinding, offering a smooth surface and tight filtration control.

Feature Integration: The inherent features of quality මල නොබැඳෙන කම්බි දැලක් – resistance to acid, alkali, chemicals, rust, and harsh weather – are non-negotiable for reliable operation in outdoor, industrial settings. High strength ensures the screen withstands the dynamic loads within trommel drums or vibrating scalper decks. Durability directly translates to reduced replacement frequency and lower operating costs.

HEBEI WEICHUN leverages its deep manufacturing expertise to guide wholesalers in selecting the perfect synergy of material, weave, and specifications for their clients' specific challenges, ensuring peak trommel and scalper performance.

FAQs About Our Trommel & Scalper Wire Mesh Screens

What are the main advantages of stainless wire mesh?

Stainless wire mesh delivers unparalleled advantages for trommels and scalpers. Its exceptional resistance to rust and corrosion drastically outperforms carbon steel, especially in wet, acidic, or saline environments common in mining, recycling, and composting. This translates directly to significantly extended screen life, reducing costly downtime for replacements. It offers superior strength and durability to withstand heavy impact and abrasion from rocks and debris. Grades like 316/316L provide excellent resistance to chemicals and harsh weather. Furthermore, it maintains high open area and precise apertures for efficient screening, offers a cleaner, brighter appearance, and ensures non-contamination of processed materials. Ultimately, it provides the lowest total cost of ownership despite a potentially higher initial investment.

How does woven wire mesh improve screening?

Woven wire mesh is fundamental to efficient screening. Its precise, consistent weaving process guarantees exact and uniform aperture sizes, critical for accurate particle separation and product quality control. Compared to alternatives like punched plate, weaving enables a much higher percentage of open area, maximizing material throughput and screening capacity. The interlaced wire structure creates inherent stability and rigidity, preventing deformation under load and maintaining aperture accuracy throughout the screen's life. Different weave types (Twill, Dutch, Crimp) are engineered to optimize material flow, resist blinding or pegging, and provide exceptional strength for heavy impact, allowing precise tailoring of the screen to specific application demands for peak trommel and scalper efficiency.

Why choose stainless over other wire mesh materials?

While mild steel or other alloys might seem cheaper initially, මල නොබැඳෙන කම්බි දැලක් is the superior long-term investment. Other materials, especially carbon steel, are highly susceptible to rapid corrosion and rust in typical screening environments, leading to premature failure, structural weakness, and frequent, costly panel replacements. Stainless steel's inherent corrosion resistance ensures vastly longer service life and reliability. It also offers higher tensile strength and better wear resistance against abrasive materials. Crucially, stainless steel maintains its integrity in harsh weather and chemical exposure, whereas alternatives degrade quickly. For wholesalers, offering stainless means providing clients with solutions that minimize downtime and operational costs, enhancing their reputation for supplying durable, high-performance components.

Can you customize wire mesh screens specifically?

Absolutely. HEBEI WEICHUN specializes in custom wire mesh solutions for trommels and scalpers. We understand that off-the-shelf panels rarely fit every unique application. We can tailor:

ද්රව්ය: Selecting the optimal stainless steel grade (304, 316, 430, etc.) for your specific environmental and chemical exposure.

Weave Pattern: Manufacturing the ideal woven wire mesh structure (Plain, Twill, Dutch, Crimp, etc.) to match your material type, size fraction, and blinding resistance needs.

Aperture Size & Wire Diameter: Precisely engineering the opening size and wire gauge for your required cut point and durability.

Panel Dimensions & Hook/Edge Configurations: Fabricating panels to exact trommel drum or scalper deck specifications, including custom hook styles, bolting patterns, or tensioning systems. We work closely with wholesalers to translate client requirements into precisely engineered, high-performance wire mesh screens.

What ensures your wire mesh screens' exceptional durability?

Our wire mesh screens achieve exceptional durability through a combination of premium materials, advanced manufacturing, and rigorous quality control. We exclusively use high-grade stainless steel (304, 316, 430, etc.), chosen for its inherent resistance to corrosion, rust, chemicals, and harsh weather. Our expertise lies in selecting and producing the optimal woven wire mesh patterns (Lock Crimp, Inter Crimp, Twill, Dutch) that provide maximum structural rigidity and resistance to impact and abrasion. The weaving process itself ensures wires are securely locked at intersections. Crucially, our scientific quality control system governs every step – from raw material inspection to precise weaving and final dimensional checks – guaranteeing consistent high strength, precise apertures, and freedom from defects. This commitment to quality ensures our screens withstand the toughest trommel and scalper environments, maximizing uptime for your clients.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

පුවත්Nov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

පුවත්Nov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

පුවත්Nov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

පුවත්Nov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

පුවත්Nov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

පුවත්Nov.11,2025