-

+86 15030157877

-

sales@galvanizedmetalmesh.com

දෙසැ. . 12, 2024 13:43 Back to list

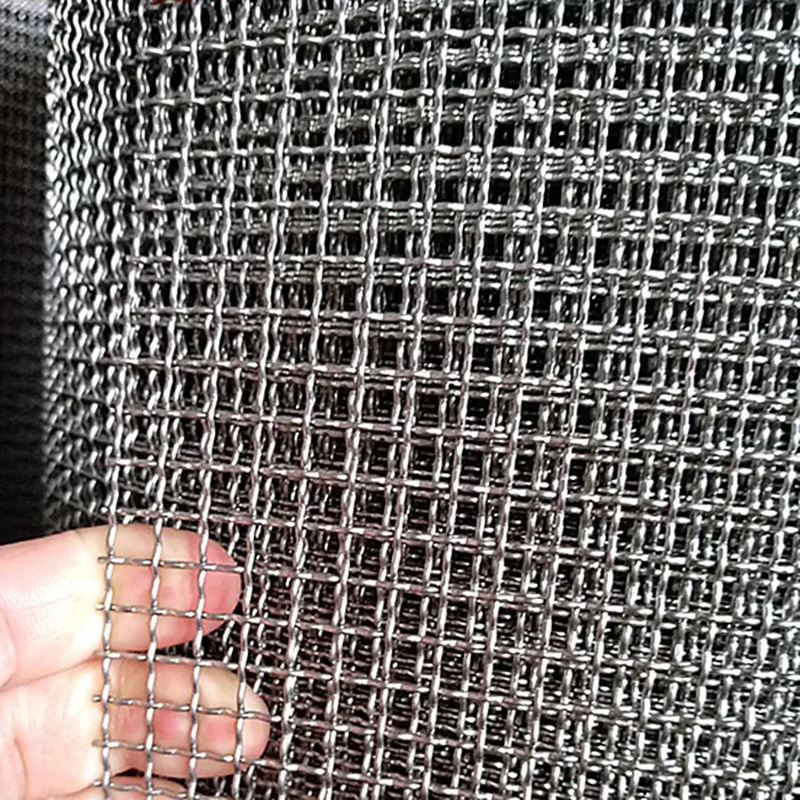

wire mesh sheet

Understanding Wire Mesh Sheets Versatile Materials for Various Applications

Wire mesh sheets are incredibly versatile materials that have found widespread use across numerous industries and applications. Composed of interwoven strands of wire forming a grid-like pattern, wire mesh sheets come in various sizes, materials, and configurations, catering to different needs. This article aims to explore the features, benefits, and potential applications of wire mesh sheets, providing a comprehensive overview for those interested in incorporating them into their projects.

Composition and Types

Wire mesh sheets can be made from several types of materials, including stainless steel, aluminum, and fiberglass. Stainless steel wire mesh is particularly popular due to its resistance to corrosion and high temperatures, making it suitable for harsh environments. Aluminum mesh is lightweight and resistant to rust, ideal for applications where weight is a concern. Fiberglass mesh, on the other hand, is often used in construction and industrial applications for its durability and resistance to chemicals.

The grid pattern of wire mesh sheets can vary, with different wire diameters and spacing options. This allows for customizability based on the purpose of the mesh sheet, whether it’s to provide sturdiness, filtration, or safety. Common configurations include welded wire mesh, woven wire mesh, and expanded metal mesh.

Benefits of Wire Mesh Sheets

One of the primary benefits of wire mesh sheets is their strength and durability

. They can withstand substantial weight and force, making them an excellent choice for fencing, reinforcement, and structural applications. Additionally, their open design offers ventilation and visibility, which is vital in environments requiring air circulation while maintaining safety and security.Wire mesh sheets are also lightweight, making them easy to handle and install. Unlike solid materials, which can be cumbersome and heavy, wire mesh offers a practical solution that does not compromise on strength. Furthermore, their versatility allows them to be easily cut or shaped to fit specific requirements, providing flexibility in design and application.

wire mesh sheet

Economically, wire mesh sheets represent a cost-effective solution. Many industries opt for wire mesh due to its longevity and reduced need for maintenance compared to other materials. This longevity translates to lower lifecycle costs, enhancing overall project profitability.

Applications

The applications of wire mesh sheets are vast and varied. In construction, they are often used as reinforcement in concrete slabs, walls, and sidewalks, ensuring structural integrity. Additionally, they serve as safety barriers on construction sites, preventing falls and accidents.

In agriculture, wire mesh sheets can be used for fencing, allowing livestock management while keeping animals safe and secure. They are also utilized for crop protection, preventing pests from damaging plants while allowing for air, light, and water to penetrate.

In industrial settings, wire mesh sheets are employed in machine guards, conveyor systems, and sorting applications. They provide a protective barrier, ensuring the safety of workers while maintaining productivity. Additionally, filtration systems utilize wire mesh to separate materials, such as in mining and food production.

Wire mesh sheets are also popular in art and design. Designers often incorporate them into furniture, decor, and architectural features for a modern, industrial look. The aesthetic appeal of wire mesh combined with its functionality makes it a favorite among architects and interior designers.

Conclusion

In summary, wire mesh sheets are progressively becoming indispensable in numerous sectors due to their durability, adaptability, and cost-effectiveness. Whether in construction, agriculture, industrial applications, or creative designs, wire mesh sheets continue to provide innovative solutions that meet the demands of an ever-evolving market. As technology advances and new materials emerge, the potential uses for wire mesh sheets will only expand, solidifying their role as a foundational element in modern applications. Understanding the various types and benefits of wire mesh can empower individuals and businesses to make informed decisions on their next projects, enhancing both functionality and aesthetics.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025