-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜன . 25, 2025 02:24 Back to list

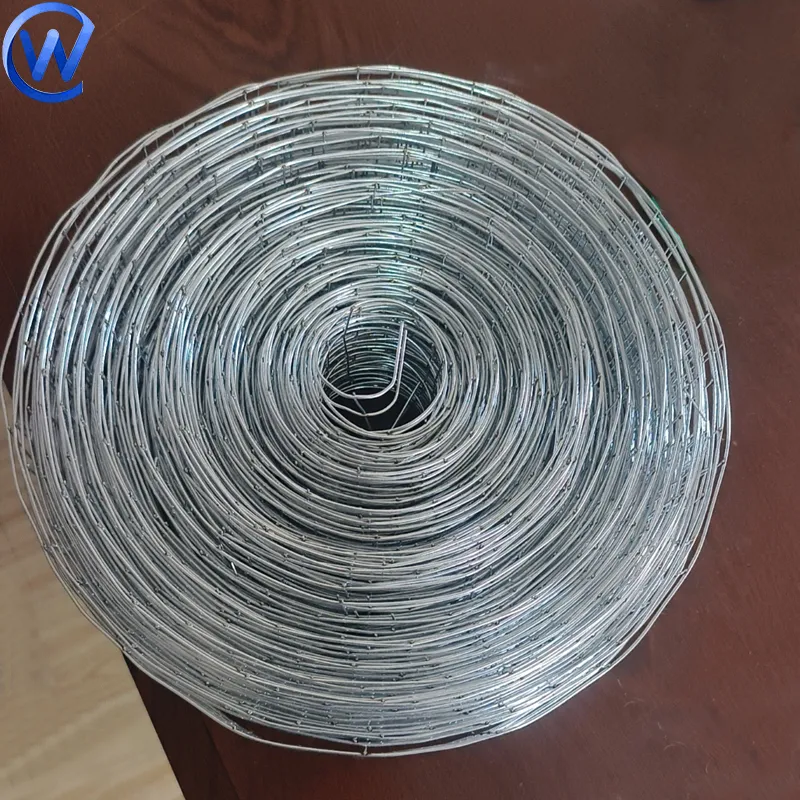

carbon steel wire

The journey of discovering the versatility and excellence of carbon steel wire begins by exploring its fundamental properties and applications across various industries. Renowned for its affordability, strength, and flexibility, carbon steel wire competes fiercely with other materials, offering both reliability and efficiency. With industries increasingly seeking materials that can balance performance and cost-effectiveness, carbon steel wire stands out as a pivotal component that meets these demands.

Delving into the authoritative perspectives, carbon steel wire holds a significant position in industrial standards and compliance. Its production and utilization are governed by international standards such as those set forth by the ASTM (American Society for Testing and Materials) and the International Organization for Standardization (ISO). These bodies ensure that carbon steel wire meets rigorous criteria for quality and safety, thereby establishing trust among manufacturers and consumers alike. Consequently, when companies adhere to these standards, they not only enhance the credibility of their products but also contribute to the overall safety and efficiency within various operational contexts. Trustworthiness in the realm of carbon steel wire manifests in the form of long-standing relationships between suppliers, manufacturers, and end-users. The confidence in its performance is reflected in the feedback from industries utilizing carbon steel wire extensively. Construction firms report reduced structural failures, while automotive companies note an increase in vehicle longevity attributed to the robust nature of carbon steel wire components. These testimonials, backed by years of application, reinforce its reputation as a dependable material choice. In conclusion, carbon steel wire not only exemplifies a product that embodies strength and flexibility but also showcases the intersection of expert craftsmanship, authoritative standards, and trustworthy performance. As industrial demands evolve, carbon steel wire continues to adapt, leveraging technological advancements to enhance its qualities. The ongoing research and development in metallurgy promise even greater innovations, ensuring that carbon steel wire remains at the forefront of material choice for years to come. By understanding the nuanced properties and applications of carbon steel wire, stakeholders can make informed decisions, ultimately driving progress across multiple industries.

Delving into the authoritative perspectives, carbon steel wire holds a significant position in industrial standards and compliance. Its production and utilization are governed by international standards such as those set forth by the ASTM (American Society for Testing and Materials) and the International Organization for Standardization (ISO). These bodies ensure that carbon steel wire meets rigorous criteria for quality and safety, thereby establishing trust among manufacturers and consumers alike. Consequently, when companies adhere to these standards, they not only enhance the credibility of their products but also contribute to the overall safety and efficiency within various operational contexts. Trustworthiness in the realm of carbon steel wire manifests in the form of long-standing relationships between suppliers, manufacturers, and end-users. The confidence in its performance is reflected in the feedback from industries utilizing carbon steel wire extensively. Construction firms report reduced structural failures, while automotive companies note an increase in vehicle longevity attributed to the robust nature of carbon steel wire components. These testimonials, backed by years of application, reinforce its reputation as a dependable material choice. In conclusion, carbon steel wire not only exemplifies a product that embodies strength and flexibility but also showcases the intersection of expert craftsmanship, authoritative standards, and trustworthy performance. As industrial demands evolve, carbon steel wire continues to adapt, leveraging technological advancements to enhance its qualities. The ongoing research and development in metallurgy promise even greater innovations, ensuring that carbon steel wire remains at the forefront of material choice for years to come. By understanding the nuanced properties and applications of carbon steel wire, stakeholders can make informed decisions, ultimately driving progress across multiple industries.

Next:

Latest news

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025