-

+86 15030157877

-

sales@galvanizedmetalmesh.com

டிசம்பர் . 22, 2024 21:49 Back to list

concrete reinforcement steel wire mesh factory

The Role of Concrete Reinforcement Steel Wire Mesh in Modern Construction

Concrete is one of the most widely used building materials globally, renowned for its strength and durability. However, in its natural state, concrete is prone to cracking and can fail under tensile stress. To enhance its structural integrity, engineers and architects turn to concrete reinforcement steel wire mesh, a crucial component in modern construction that significantly improves the performance and longevity of concrete structures.

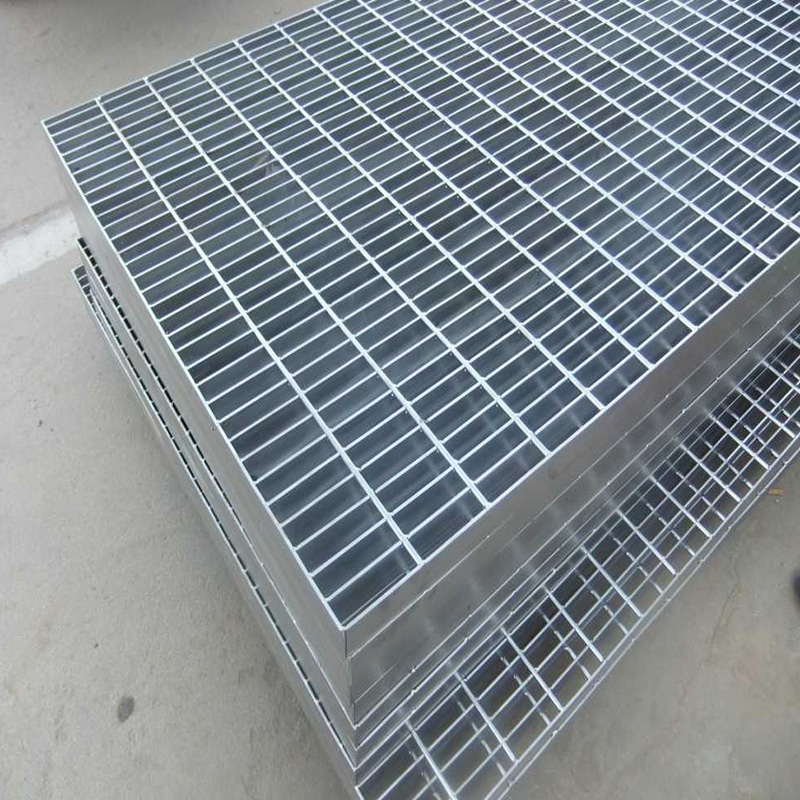

Steel wire mesh, often simply referred to as wire mesh or rebar mesh, consists of a grid of steel wires arranged in a specific pattern. This configuration allows the mesh to effectively distribute loads and absorb tensile forces, which concrete alone cannot handle well. The primary function of steel wire mesh in concrete is to provide reinforcement, preventing cracks and deformations that can compromise a structure's safety and durability over time.

One of the most significant advantages of using steel wire mesh is its ability to enhance the overall tensile strength of concrete. When concrete sets, it is very strong in compression but weak in tension. This is where the synergy between concrete and steel becomes evident. The steel wire mesh acts as a tensioning agent that works in harmony with the concrete, allowing the composite material to withstand various stresses encountered in real-world applications. This is particularly important in elements subjected to dynamic loads, such as floors, roofs, and pavements.

Moreover, the use of steel wire mesh contributes to cost-effectiveness in construction projects. As it improves the structural integrity of concrete elements, there may be less need for thicker slabs or additional reinforcement, which can lead to material savings. This not only reduces expenditure on materials but also decreases labor costs and construction time. The ease of installation associated with steel wire mesh further enhances its attractiveness; it can be easily cut to size and laid out in the designated areas, allowing for rapid and efficient project execution.

concrete reinforcement steel wire mesh factory

In addition to providing tensile strength, steel wire mesh also offers other benefits. Its use helps to control cracking, which is essential for maintaining the aesthetic appearance and functionality of surfaces like driveways and decks. Uncontrolled cracking can lead to significant repairs and maintenance issues over time. By utilizing steel wire mesh, builders can enhance the resilience of surfaces, ensuring they remain intact and attractive for years to come.

The production process of concrete reinforcement steel wire mesh involves sourcing high-quality steel, which is then processed and fabricated into specific sizes and configurations to meet the demands of various projects. Factories specializing in steel wire mesh production adopt precise manufacturing techniques to ensure that the final product meets strict quality standards. This includes compliance with industry regulations and performance specifications, ensuring that the mesh will withstand the rigors of its intended application.

As construction practices continue to evolve, the integration of advanced materials and technologies becomes increasingly important. The development of new types of steel wire meshes, such as those with enhanced corrosion resistance, promises to further extend the lifespan of concrete structures. Innovations in manufacturing processes are also leading to improved efficiency and sustainability, reducing the environmental impact of construction procedures.

In conclusion, concrete reinforcement steel wire mesh plays a vital role in modern construction, offering significant benefits in terms of strength, durability, cost-effectiveness, and aesthetic maintenance of concrete structures. As the industry continues to innovate, the importance of this reinforcement method will only grow, cementing its status as an indispensable component in the construction of safe and long-lasting buildings and infrastructure.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025