-

+86 15030157877

-

sales@galvanizedmetalmesh.com

டிசம்பர் . 01, 2024 03:20 Back to list

custom crimped woven wire mesh

The Versatility and Applications of Custom Crimped Woven Wire Mesh

Introduction

In the realm of industrial materials, custom crimped woven wire mesh stands out as an exceptionally versatile product. With its unique construction features and myriad applications, this material is becoming increasingly essential in various sectors such as mining, filtration, agriculture, and construction. This article delves into the characteristics, manufacturing process, and wide-ranging applications of crimped woven wire mesh, emphasizing its significance in today's market.

Understanding Crimped Woven Wire Mesh

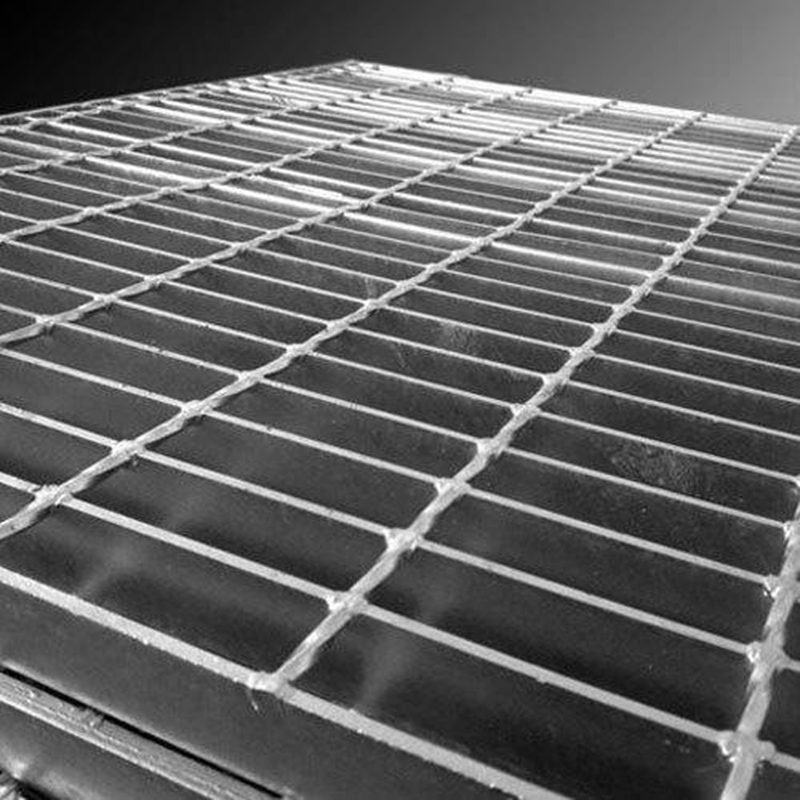

Crimped woven wire mesh is made by weaving crimped wires together. The crimping process involves bending the wires in a wave-like pattern, which not only enhances the mesh's structural integrity but also improves its overall strength. This unique weaving technique allows the mesh to maintain its shape under stress and provides excellent filtering capabilities.

The crimped wires can be made from a variety of materials, including stainless steel, galvanized steel, aluminum, and other alloys. Each material offers different benefits such as rust resistance, weight, and strength, allowing for customization based on specific application requirements. The wire diameter, crimp pattern, mesh opening size, and overall dimensions can all be tailored to meet the unique needs of different industries.

Manufacturing Process

The manufacturing of custom crimped woven wire mesh involves several steps. First, the desired wire material is selected and cut to length. The next step is crimping, where the wire is bent using specialized equipment to achieve the desired wave pattern. Once the wires are crimped, they are woven together using weaving machines, which can be configured to produce various mesh patterns and openings.

Quality control is a vital aspect of the manufacturing process. Each batch of mesh undergoes rigorous testing to ensure that it meets specific strength, durability, and size specifications. This focus on quality ensures that the final product will perform reliably in its intended application.

custom crimped woven wire mesh

Applications Across Industries

1. Mining and Quarrying In the mining industry, crimped woven wire mesh is utilized for screening and filtering materials. Its sturdy construction allows it to endure the harsh conditions of mining operations, effectively separating minerals and ores from unwanted materials.

2. Filtration Many filtration systems use crimped woven wire mesh due to its excellent pore size control and durability. Applications range from water treatment plants to industrial filtrations where the material needs to withstand high flow rates and pressure.

3. Agriculture Farmers often employ crimped woven wire mesh for fencing, which effectively keeps livestock contained while allowing air and light to pass through. Additionally, it can be used in crop protection systems, preventing pests from damaging valuable crops.

4. Construction and Architecture The construction industry uses crimped woven wire mesh in concrete reinforcement, providing additional strength and structure to concrete slabs and walls. Moreover, architects appreciate its aesthetic potential in design projects, where it can serve both functional and decorative purposes.

5. Automotive and Aerospace Custom crimped woven wire mesh can also be found in the automotive and aerospace industries as part of filtration systems and safety screens. Its ability to withstand high temperatures and pressures makes it an ideal choice for these demanding applications.

Conclusion

The significance of custom crimped woven wire mesh cannot be understated. Its versatility, coupled with the ability to customize according to specific needs, makes it an invaluable product across multiple sectors. From enhancing safety and performance in automobiles to improving agricultural productivity, this innovative material plays a crucial role in modern applications. As industries continue to evolve, the demand for high-quality crimped woven wire mesh is likely to grow, reaffirming its status as a fundamental component in numerous manufacturing and construction processes. With its combination of strength, durability, and adaptability, crimped woven wire mesh is set to remain a vital material for years to come.

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025