-

+86 15030157877

-

sales@galvanizedmetalmesh.com

நவ் . 25, 2024 07:05 Back to list

Custom Galvanized Welded Wire Mesh for Various Applications and Needs

Custom Galvanized Weld Wire Mesh Versatile Solutions for Various Applications

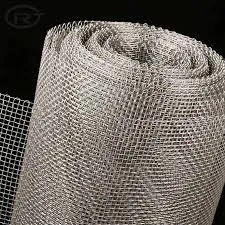

In today's industrial landscape, the demand for high-quality materials is paramount, and one of the top choices for reinforcement and support structures is custom galvanized weld wire mesh. This versatile material, typically made from steel wire, is welded at intersections and then galvanized to prevent corrosion and enhance durability. Its popularity spans various industries, including construction, agriculture, and manufacturing, making it a crucial component in a wide array of applications.

Understanding Galvanized Weld Wire Mesh

Galvanized weld wire mesh consists of a grid-like pattern formed by welding horizontal and vertical wires together. The galvanized coating involves dipping the welded mesh in a zinc solution, providing a protective layer that prevents rust and extends the mesh's lifespan. This process offers significant advantages over non-galvanized alternatives, particularly in environments exposed to moisture or corrosive elements.

Applications of Custom Galvanized Weld Wire Mesh

1. Construction and Reinforcement One of the primary uses of custom galvanized weld wire mesh is in the construction industry, where it’s employed for reinforcing concrete structures. By integrating the mesh within concrete slabs, walls, or pavements, it enhances the structural integrity, reduces cracking, and provides essential tensile strength. Custom sizing allows engineers and builders to tailor the mesh dimensions to meet specific project requirements effectively.

2. Agriculture and Animal Husbandry In agriculture, galvanized weld wire mesh serves a pivotal role in various applications, such as fencing for livestock and garden borders. Its robust structure prevents animals from escaping while keeping predators out. Additionally, it can be used to create trellises for climbing plants, ensuring optimal growth while minimizing damage.

custom galvanized weld wire mesh

3. Manufacturing and Industrial Uses The manufacturing sector often utilizes custom welded mesh for processing and sorting materials. It is common in conveyor systems, where the mesh can allow for drainage and airflow while providing a sturdy support structure. Mesh panels are also used in the fabrication of safety guards, protective screens, and shelving units within industrial settings.

4. Architectural and Decorative Elements Beyond functional applications, custom galvanized weld wire mesh increasingly finds its way into modern architectural designs. Its aesthetic appeal can enhance both interior and exterior spaces, serving as a stylish barrier, partition, or decorative element. The versatility of the mesh allows it to be designed in various patterns and configurations, making it suitable for innovative architectural projects.

Benefits of Custom Solutions

Opting for custom galvanized weld wire mesh allows businesses to meet their specific needs more accurately. Customization offers the flexibility to adjust dimensions, wire gauges, and mesh openings to suit particular requirements. Moreover, businesses can choose the finish, such as pre-galvanized or hot-dip galvanized, depending on the exposure levels of the intended application.

Furthermore, using custom solutions can lead to cost efficiency. Tailoring the mesh to meet exact specifications minimizes waste during production and installation. This approach not only saves money but also aligns with sustainable practices, making it an eco-friendly option.

Conclusion

In conclusion, custom galvanized weld wire mesh is a multipurpose material that plays a vital role across different sectors. With its durability, resistance to corrosion, and versatility, it stands out as an essential component in modern applications ranging from construction to agriculture and creative architectural designs. By choosing customized solutions, companies can ensure that they are adequately addressing their unique needs while benefiting from increased efficiency and performance. As industries continue to evolve, the role of custom galvanized weld wire mesh will undoubtedly expand, cementing its place as a fundamental construction and design element.

-

High-Quality Security Fence Supplier & Manufacturer Leading Exporter

NewsJun.24,2025

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025