-

+86 15030157877

-

sales@galvanizedmetalmesh.com

பிப் . 03, 2025 04:03 Back to list

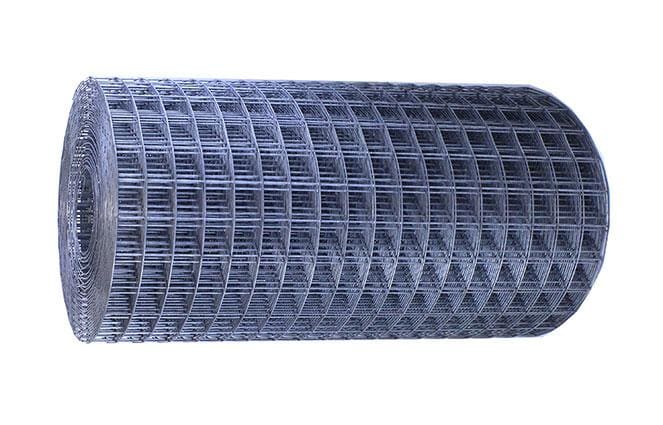

pvc coated welded wire mesh

Custom PVC coated galvanized wire stands out as a versatile and durable material, offering numerous applications across various industries. Known for its remarkable strength and resilience, this unique wire is essential for projects demanding both functionality and aesthetics. The combination of galvanization and PVC coating provides a fortified solution that meets the stringent requirements of modern-day applications.

The rise of urban gardening and balcony horticulture has seen an increased demand for customized PVC coated galvanized wire. Enthusiasts of this green trend rely on the wire for making sturdy plant trellises and cages, facilitating vertical growth in limited spaces. Its weather-resistant nature ensures the longevity of these structures, supporting plants through different seasons and growth stages. Security applications further emphasize the wire’s importance. It's a staple in the design of perimeter fencing, barbed wire, and razor wire installations for both residential and commercial properties. The enhanced durability and protective PVC layer deter intruders, offering a reliable security measure for safeguarding property and assets. For custom orders, manufacturers provide a variety of options, tailoring the wire to specific project needs. Customers can specify the size, length, color, and even the thickness of the PVC coating. This customization ensures that each project, whether large-scale or personal, receives a product that perfectly fits its unique demands. Sustainability has also become a critical factor in choosing materials, and PVC coated galvanized wire does not disappoint. Many manufacturers are now focusing on eco-friendly processes and materials, ensuring that their products have a minimal environmental footprint. By opting for this wire, businesses and individuals contribute to more sustainable practices, aligning with global efforts towards environmental conservation. In conclusion, custom PVC coated galvanized wire represents an optimal choice for various applications demanding durability, flexibility, and aesthetic appeal. Its widespread use across different domains showcases its capability to meet diverse needs while adhering to high standards of quality and sustainability. By selecting this material, one can rest assured of a reliable, long-lasting solution that harmonizes performance with visual appeal.

The rise of urban gardening and balcony horticulture has seen an increased demand for customized PVC coated galvanized wire. Enthusiasts of this green trend rely on the wire for making sturdy plant trellises and cages, facilitating vertical growth in limited spaces. Its weather-resistant nature ensures the longevity of these structures, supporting plants through different seasons and growth stages. Security applications further emphasize the wire’s importance. It's a staple in the design of perimeter fencing, barbed wire, and razor wire installations for both residential and commercial properties. The enhanced durability and protective PVC layer deter intruders, offering a reliable security measure for safeguarding property and assets. For custom orders, manufacturers provide a variety of options, tailoring the wire to specific project needs. Customers can specify the size, length, color, and even the thickness of the PVC coating. This customization ensures that each project, whether large-scale or personal, receives a product that perfectly fits its unique demands. Sustainability has also become a critical factor in choosing materials, and PVC coated galvanized wire does not disappoint. Many manufacturers are now focusing on eco-friendly processes and materials, ensuring that their products have a minimal environmental footprint. By opting for this wire, businesses and individuals contribute to more sustainable practices, aligning with global efforts towards environmental conservation. In conclusion, custom PVC coated galvanized wire represents an optimal choice for various applications demanding durability, flexibility, and aesthetic appeal. Its widespread use across different domains showcases its capability to meet diverse needs while adhering to high standards of quality and sustainability. By selecting this material, one can rest assured of a reliable, long-lasting solution that harmonizes performance with visual appeal.

Next:

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025