-

+86 15030157877

-

sales@galvanizedmetalmesh.com

நவ் . 29, 2024 19:43 Back to list

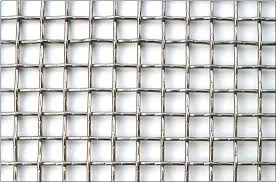

High-Quality Custom Quarry Screening Mesh for Optimal Material Separation

Custom Quarry Screen Mesh A Vital Component for Efficient Mineral Processing

In the world of mineral processing, the importance of quality screening cannot be overstated. Quarry screen mesh is a critical element used not only to separate different sizes of materials but also to ensure the efficiency of various operations in the quarrying process. Custom quarry screen mesh plays a significant role in optimizing production and maintaining the desired quality of materials, catering to the unique demands of different projects.

Quarry screen mesh is typically made from high-quality materials such as stainless steel, carbon steel, or other alloys, providing durability and resistance to wear and tear. This durability is essential, as the screening process often involves heavy, abrasive materials that can easily damage inferior mesh. By opting for custom solutions, businesses can tailor the mesh specifications, including opening size, wire diameter, and overall dimensions, to match their exact requirements. This customization allows operators to achieve better separation and higher throughput rates, resulting in increased efficiency and productivity.

The intricacy of mining operations necessitates specialized solutions. Each quarry presents its own set of challenges – from the type of material being processed to the specific sizes required for final products. Custom quarry screen meshes can be designed with various mesh opening configurations, such as square, rectangular, or even custom shapes. The ability to adapt the mesh design to cope with different mining conditions ensures that operators can efficiently manage the flow of materials while minimizing the risk of clogging.

custom quarry screen mesh

One major advantage of custom quarry screen mesh is its ability to enhance the quality of the end product. In many instances, recycled materials and aggregates need to meet specific standards for construction or other applications. By utilizing a mesh that is specifically designed to meet these standards, operators can ensure the consistency and reliability of their output. This not only saves time but also reduces financial losses associated with rework or rejected materials.

Additionally, custom quarry screen meshes offer flexibility in terms of installation and maintenance

. Many of these products are designed for easy installation in existing screening systems, which can significantly reduce downtime. Furthermore, their tailored sizes and materials can also contribute to easier and more effective cleaning and maintenance routines, ultimately leading to prolonged service life and lower operational costs.The market for custom quarry screen mesh is growing due to increasing demand for efficiency and productivity in the construction and mining industries. Companies specializing in this field employ advanced manufacturing techniques and quality assurance processes to ensure that their products meet the highest standards. As the industry continues to evolve, so too does the technology behind quarry screen mesh, paving the way for innovative solutions that will improve performance, reduce environmental impact, and increase profitability.

In conclusion, custom quarry screen mesh is an indispensable asset for any quarry operator. By providing tailored solutions that enhance efficiency, product quality, and operational flexibility, it helps businesses not only meet but exceed their production goals. Investing in high-quality, custom-designed screen mesh is a strategic move that can lead to significant long-term benefits in the competitive landscape of mineral processing.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025