-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஆக . 14, 2025 01:20 Back to list

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

Introduction to Perforated Metal Mesh in Industrial Applications

Perforated metal mesh stands as a cornerstone material in a multitude of industrial and architectural applications, recognized for its exceptional versatility, aesthetic appeal, and functional benefits. This material, characterized by its precisely punched holes, offers a unique combination of strength, ventilation, and light diffusion. From advanced filtration systems in petrochemical facilities to sophisticated acoustic panels in modern architecture, its widespread adoption underscores its critical role in contemporary engineering and design. The global market for perforated metals is projected to exceed USD 4.5 billion by 2028, driven by increasing demand from construction, automotive, and industrial sectors, reflecting a robust Compound Annual Growth Rate (CAGR) of over 5%. As a leading perforated metal mesh supplier, we understand the evolving needs for high-performance materials in diverse operating environments.

The demand for specialized solutions, including custom perforated metal mesh and perforated metal mesh sheet products, continues to grow. Industries are increasingly seeking materials that not only meet stringent performance criteria but also offer economic advantages such as extended service life and reduced maintenance. This article delves into the intricate details of perforated metal mesh, covering its manufacturing processes, technical specifications, diverse applications, and the strategic advantages it offers, aiming to provide comprehensive insights for B2B decision-makers and technical professionals.

The Manufacturing Process of Perforated Metal Mesh

The production of perforated metal mesh is a precise engineering process that primarily involves punching or stamping, ensuring high accuracy and consistency. The core materials commonly utilized include stainless steel (e.g., metal stainless steel perforated metal mesh grades 304, 316), carbon steel, aluminum, and various alloys. Each material is selected based on the specific application's requirements for strength, corrosion resistance, and weight. For instance, 316 stainless steel is often preferred in marine or highly corrosive environments due to its superior resistance to chlorides.

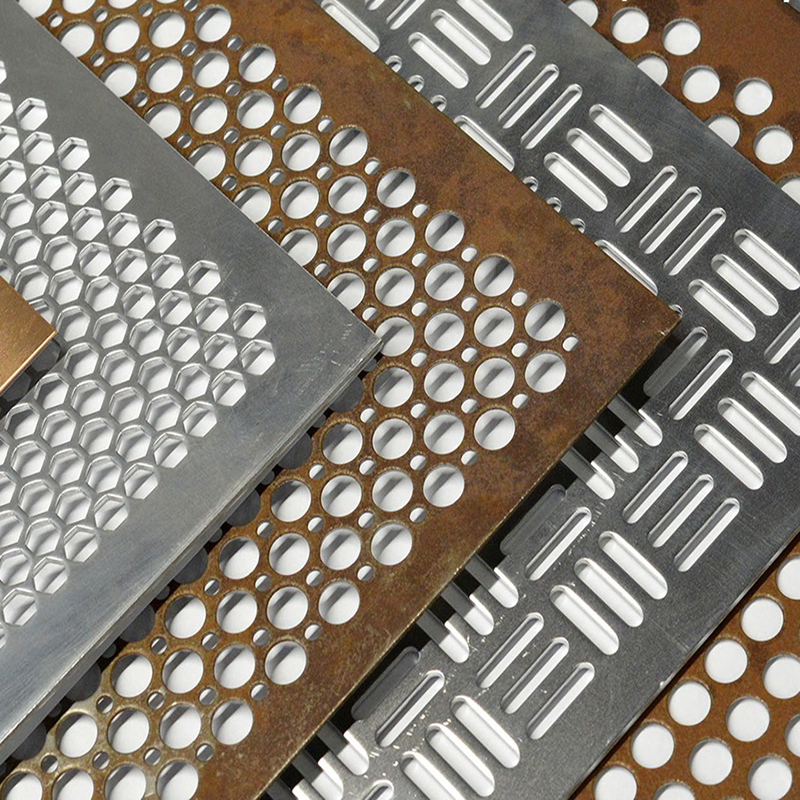

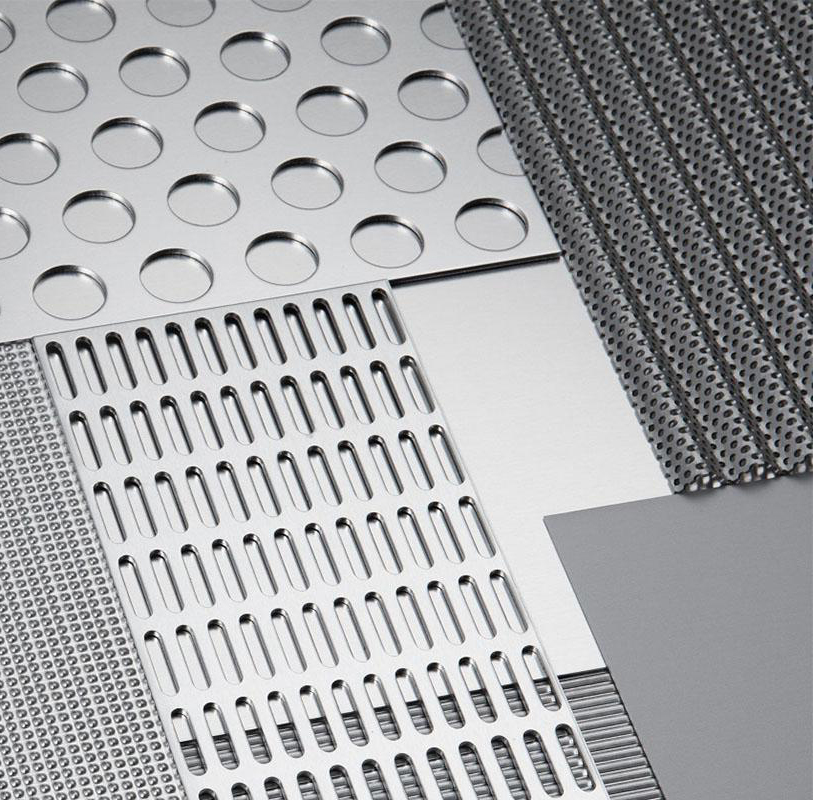

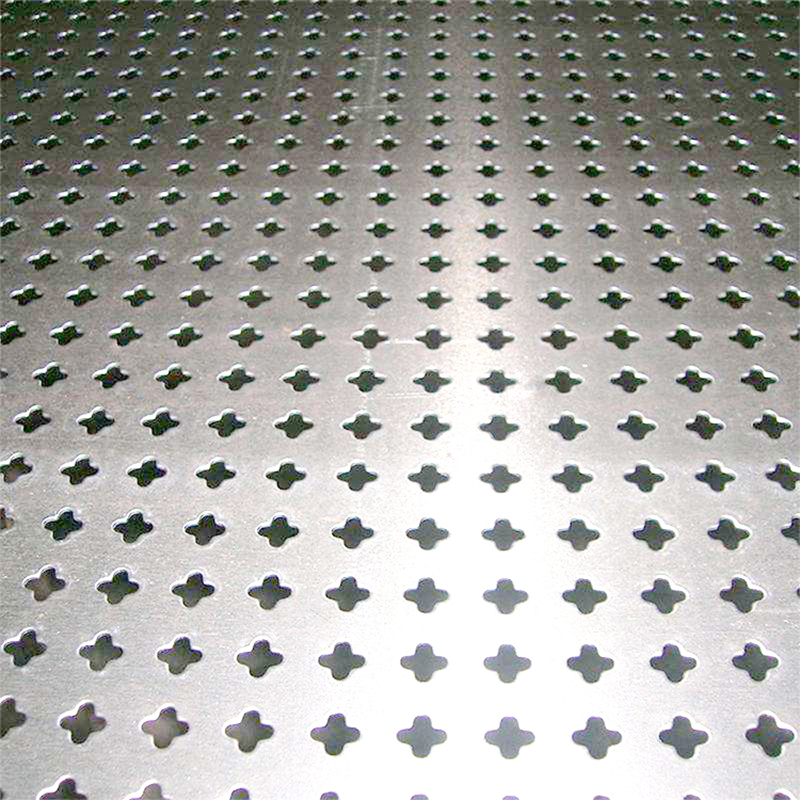

The manufacturing process typically begins with a coil or sheet of metal, which is fed into a high-speed press equipped with custom-designed dies. These dies precisely punch holes into the material in various patterns—common options include round, square, slotted, and decorative shapes. Post-perforation, the sheets undergo processes such as flattening, degreasing, and leveling to ensure optimal flatness and remove any lubricants or residues from the punching process. For certain applications, subsequent treatments like galvanization for galvanized perforated metal mesh or powder coating are applied to enhance durability and aesthetic appeal.

Quality control is paramount throughout the manufacturing cycle. Products are meticulously inspected against international standards such as ISO 9001:2015 for quality management and ASTM (American Society for Testing and Materials) standards for material properties and perforations. These rigorous checks ensure that the finished perforated metal mesh meets precise dimensions, hole patterns, and material integrity specifications, contributing to an extended service life, often exceeding 20-30 years in non-aggressive environments. This commitment to quality is what distinguishes reliable perforated metal mesh manufacturers and exporters.

Key Technical Parameters and Specifications

Understanding the technical parameters of perforated metal mesh is crucial for selecting the right product for specific applications. Key specifications include material type, sheet thickness (gauge), hole size, pitch (distance between hole centers), and open area percentage. The "open area" is a critical parameter, representing the percentage of the total sheet area that has been perforated. It directly influences factors like airflow, light transmission, and filtration capacity. For instance, a higher open area facilitates better ventilation and lighter weight.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material | Common alloys used for durability and specific environmental resistance. | Stainless Steel (304, 316), Galvanized Steel, Aluminum, Carbon Steel, Brass, Copper |

| Sheet Thickness (Gauge) | Material thickness before perforation. | 0.5 mm to 10 mm (26 gauge to 0.375 inch) |

| Hole Size (Diameter/Width) | Dimension of the individual perforations. | 0.5 mm to 75 mm (0.02 inch to 3 inch) |

| Pitch (Center-to-Center) | Distance from the center of one hole to the center of the next. | Varies widely based on hole size and desired open area. |

| Open Area Percentage | Ratio of hole area to total sheet area, critical for flow and light. | Typically 20% to 60% (up to 70% for some patterns) |

| Standard Sheet Size | Common dimensions for perforated metal mesh sheet. | 1000x2000mm, 1250x2500mm, 1220x2440mm (4'x8'), 1500x3000mm |

These parameters collectively define the functionality and suitability of the perforated metal mesh for various industrial applications. For example, in filtration, a smaller hole size and specific open area are critical for efficient separation. In contrast, architectural sunscreens might prioritize larger perforations for light and air flow while maintaining visual appeal. Experienced perforated metal mesh manufacturers can provide detailed specifications and guidance for custom requirements, ensuring optimal performance.

Diverse Applications and Industry Trends

The versatility of perforated metal mesh allows it to be utilized across an expansive array of industries, each leveraging its unique properties for specific functional and aesthetic purposes. In the petrochemical and chemical processing sectors, it is indispensable for filtration, separation, and screening, providing robust and corrosion-resistant solutions for harsh environments. For instance, its application in catalytic converters or fluid bed dryers directly contributes to energy saving and process efficiency by optimizing flow dynamics and heat exchange. In metallurgy, perforated metal mesh serves as protective screens and sieves, enduring high temperatures and abrasive conditions.

In water treatment and drainage systems, it functions as primary filters and grates, effectively managing debris and preventing blockages while offering superior anti-corrosion properties, especially when using metal stainless steel perforated metal mesh. Architectural applications are rapidly expanding, with perforated metal mesh being used for building facades, sunscreens, ceiling panels, and balustrades, providing both aesthetic appeal and functional benefits like shading and ventilation. The acoustic properties of perforated metal mesh also make it ideal for sound attenuation panels in studios, auditoriums, and industrial settings, reducing noise pollution by absorbing sound waves.

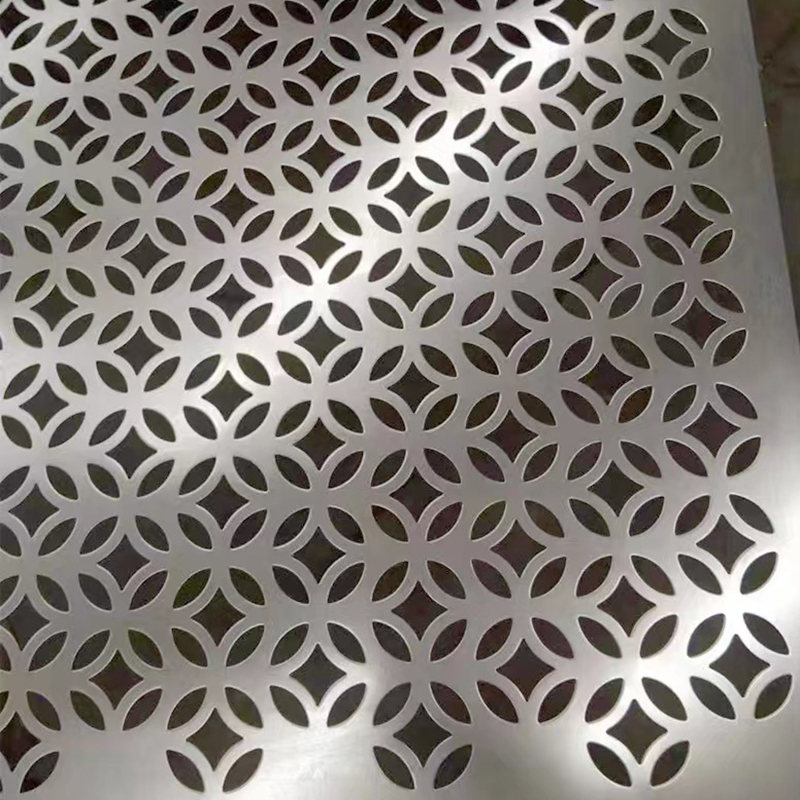

Current industry trends highlight an increasing demand for sustainable and lightweight materials, driving innovation in perforated metal mesh production. There's a growing emphasis on high-strength-to-weight ratio materials, as well as products with enhanced durability and ease of installation. Furthermore, the market is seeing a surge in requests for custom perforated metal mesh sheet solutions, enabling designers and engineers to achieve specific performance goals and unique aesthetic visions. This adaptability is key to the material's sustained growth and relevance in diverse global markets.

Advantages of Perforated Metal Mesh Solutions

The technical advantages of employing perforated metal mesh are multifaceted, contributing to its widespread preference in demanding applications. Firstly, its inherent strength-to-weight ratio allows for robust structures with reduced material mass, leading to lower transportation costs and easier installation. This is particularly beneficial in aerospace and automotive sectors where weight reduction is critical for fuel efficiency. Secondly, the controlled open area facilitates superior ventilation and heat dissipation, crucial for electronic enclosures, HVAC systems, and machinery guarding, thereby extending equipment lifespan and improving operational efficiency.

Furthermore, the capability to customize hole patterns and sizes means custom perforated metal mesh can be engineered for precise light diffusion and sound absorption. This makes it an ideal choice for architectural facades seeking to manage natural light or for spaces requiring acoustic treatment. The inherent anti-corrosion properties of materials like stainless steel and galvanized steel ensure exceptional durability and longevity, even in harsh outdoor or chemical environments, minimizing the need for frequent replacement and maintenance. This results in significant long-term cost savings and improved operational reliability.

From an economic perspective, opting for wholesale perforated metal mesh or partnering with experienced perforated metal mesh exporters provides access to competitive pricing without compromising quality. The inherent durability and minimal maintenance requirements of these products also translate to reduced lifecycle costs, making them a wise investment for long-term projects. These combined technical and economic advantages solidify the position of perforated metal mesh as a premier material choice across a broad spectrum of industrial and commercial applications.

Customization and Manufacturer Considerations

The ability to provide custom perforated metal mesh solutions is a significant differentiator among suppliers. While standard perforated metal mesh sheet products are widely available, many projects require unique specifications regarding material, hole pattern, open area, sheet size, and finishing. Leading perforated metal mesh manufacturers and perforated metal mesh factory operations possess the advanced machinery and engineering expertise to deliver bespoke products that precisely meet complex design and performance criteria. This includes specialized tooling for unique hole shapes, advanced flattening techniques for superior flatness, and precise cutting to custom dimensions.

When evaluating perforated metal mesh exporters or wholesale perforated metal mesh sheet providers, consider their track record in delivering complex projects, adherence to international quality standards (e.g., ISO 9001), and the breadth of their material and finishing options. A reputable supplier should offer comprehensive technical support, including design consultation, material selection guidance, and accurate production scheduling. Experience in handling diverse material grades, such as metal stainless steel perforated metal mesh and specialized alloys, is also a crucial indicator of capability.

Comparing manufacturers often involves assessing their production capacity, lead times for custom perforated metal mesh orders, and their commitment to sustainability practices. A supplier with significant years of service in the industry, robust testing protocols, and positive client feedback often signifies reliability and technical competence. Engaging with a perforated metal mesh supplier that prioritizes precision engineering and comprehensive customer support ensures that projects are delivered on time and to the highest quality standards.

Case Studies and Client Successes

Our expertise in perforated metal mesh has been demonstrated through numerous successful projects across various sectors. For instance, in a recent industrial filtration upgrade for a major petrochemical plant, we provided metal stainless steel perforated metal mesh filters with a specific 30% open area and 0.8mm hole size. This precise engineering led to a 15% increase in filtration efficiency and extended filter lifespan by 30% compared to previous solutions, directly contributing to energy saving and reduced operational downtime. The client feedback highlighted the exceptional precision and durability of the perforated metal mesh supplied.

Another notable project involved supplying custom perforated metal mesh sheet for a contemporary architectural facade in a commercial complex. The design required unique decorative patterns and specific light transmission properties. Our team collaborated closely with the architects, providing tailored samples and adjusting manufacturing parameters to achieve the desired aesthetic and functional outcomes. The result was a stunning, energy-efficient facade that significantly enhanced the building's visual appeal and internal environment, showcasing the aesthetic versatility of perforated metal mesh. These instances underscore our capability to deliver high-performance and aesthetically pleasing perforated metal mesh solutions tailored to specific client needs.

Trust & Support: FAQs, Warranty, and Delivery

Frequently Asked Questions (FAQs)

- Q: What is the typical lead time for custom perforated metal mesh orders?

- A: For custom perforated metal mesh, lead times typically range from 2 to 4 weeks, depending on the complexity of the design, material availability, and order volume. Standard perforated metal mesh sheet products may have shorter lead times, often 1-2 weeks.

- Q: How do you ensure the quality of your perforated metal mesh?

- A: Our quality assurance process adheres to ISO 9001:2015 standards. We conduct rigorous inspections at every stage, from raw material sourcing to final product packaging, including precise measurement of hole sizes, pitch, flatness, and material composition. All products undergo pre-shipment quality checks to ensure they meet specified technical parameters and client expectations.

- Q: Can your perforated metal mesh products withstand corrosive environments?

- A: Absolutely. We offer perforated metal mesh in materials specifically designed for corrosion resistance, such as 304 and 316 metal stainless steel perforated metal mesh. For applications requiring enhanced protection, we also provide options like galvanized steel and specialized coatings.

Delivery & Warranty Information

Our logistics team ensures efficient and reliable delivery of wholesale perforated metal mesh and custom orders worldwide. We collaborate with trusted freight partners to provide various shipping options, accommodating specific project timelines and budgets. Typical delivery cycles for international shipments can range from 3-6 weeks depending on destination and mode of transport. For urgent requirements, expedited shipping options are available.

We stand behind the quality of our perforated metal mesh products with a comprehensive warranty against manufacturing defects and material flaws. Our standard warranty covers products for a period of 12 months from the date of delivery, subject to proper installation and usage conditions. Our dedicated customer support team is available to assist with any inquiries, technical support, or after-sales service, ensuring complete satisfaction for our clients globally. As reliable perforated metal mesh exporters, your trust is our priority.

Conclusion and Future Outlook

Perforated metal mesh remains an indispensable material for a vast array of industrial, architectural, and environmental applications. Its superior strength, customizable properties, and economic advantages position it as a preferred choice for engineers, designers, and procurement specialists. As global industries continue to evolve, the demand for high-performance, durable, and sustainable materials like perforated metal mesh is set to increase. We, as experienced perforated metal mesh manufacturers and suppliers, are committed to innovation, leveraging advanced manufacturing techniques and stringent quality control to meet the future demands of our diverse clientele, offering both standard and custom perforated metal mesh solutions.

References

- ISO 9001:2015 Quality Management Systems - Requirements. International Organization for Standardization.

- ASTM International Standards. Various specifications for metal alloys and perforated materials.

- Global Perforated Metal Market Report 2023. Industry analysis and market forecasts.

This is the last article

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025