-

+86 15030157877

-

sales@galvanizedmetalmesh.com

பிப் . 12, 2025 00:21 Back to list

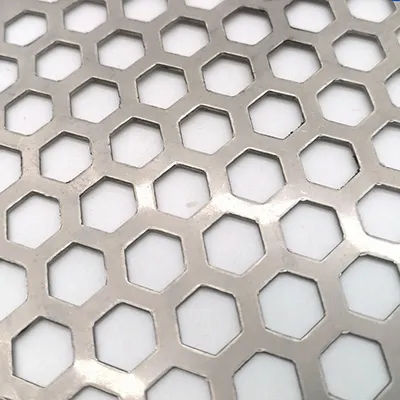

custom hexagonal wire mesh

Custom wire mesh for concrete applications has become an essential component in modern construction, offering a blend of durability, versatility, and cost-effectiveness. This specialized mesh plays a crucial role in reinforcing concrete structures, ensuring stability, and longevity. My personal experience with custom wire mesh underscores its importance in enhancing the structural integrity of various construction projects.

Additionally, custom wire mesh minimizes wastage. By providing an exact match to the project's specifications, there is less material left over, which in turn reduces costs. I once consulted for a project that matched each panel of wire mesh precisely to the dimensions required, avoiding costly overages and thus proving budget efficiency. Such efficiency not only benefits the project financially but also supports sustainable construction practices by reducing excess material use. Moreover, the adaptability of custom wire mesh allows for innovations in design and structural engineering. In my practice, I've seen architects and engineers push the boundaries of traditional design by utilizing mesh configurations that standard options cannot support. Whether it's the creation of complex shapes or the reinforcement of unconventional structures, custom wire mesh provides the flexibility needed to realize these innovative ideas while maintaining structural integrity. Custom wire mesh also supports quicker installation processes, a significant advantage in fast-paced construction projects. Because the mesh is designed to fit the exact needs of a project, it often requires less cutting and fitting on-site, accelerating construction timelines and reducing labor costs. This efficiency not only speeds up the completion of projects but also lessens the potential for errors during installation, further ensuring the safety and stability of the structure. In conclusion, the use of custom wire mesh in concrete offers significant advantages in terms of structural integrity, cost-efficiency, and project adaptability. Drawing from my own experiences, as well as industry expertise and authority, it is evident that custom wire mesh provides a trustworthy solution for modern construction challenges. Whether reinforced concrete is needed for residential buildings, commercial infrastructures, or complex architectural designs, custom wire mesh remains a cornerstone material, ensuring structures are built to last with precision and reliability.

Additionally, custom wire mesh minimizes wastage. By providing an exact match to the project's specifications, there is less material left over, which in turn reduces costs. I once consulted for a project that matched each panel of wire mesh precisely to the dimensions required, avoiding costly overages and thus proving budget efficiency. Such efficiency not only benefits the project financially but also supports sustainable construction practices by reducing excess material use. Moreover, the adaptability of custom wire mesh allows for innovations in design and structural engineering. In my practice, I've seen architects and engineers push the boundaries of traditional design by utilizing mesh configurations that standard options cannot support. Whether it's the creation of complex shapes or the reinforcement of unconventional structures, custom wire mesh provides the flexibility needed to realize these innovative ideas while maintaining structural integrity. Custom wire mesh also supports quicker installation processes, a significant advantage in fast-paced construction projects. Because the mesh is designed to fit the exact needs of a project, it often requires less cutting and fitting on-site, accelerating construction timelines and reducing labor costs. This efficiency not only speeds up the completion of projects but also lessens the potential for errors during installation, further ensuring the safety and stability of the structure. In conclusion, the use of custom wire mesh in concrete offers significant advantages in terms of structural integrity, cost-efficiency, and project adaptability. Drawing from my own experiences, as well as industry expertise and authority, it is evident that custom wire mesh provides a trustworthy solution for modern construction challenges. Whether reinforced concrete is needed for residential buildings, commercial infrastructures, or complex architectural designs, custom wire mesh remains a cornerstone material, ensuring structures are built to last with precision and reliability.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025