-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 23, 2025 13:05 Back to list

Expanded Metal Mesh - Custom, Durable, Wholesale

Why Expanded Metal Mesh still sets the standard in 2025

I spent a day in South Industrial Zone 07, Anping County, Hebei — the unofficial hometown of wire and mesh — and, to be honest, I came back impressed. You can feel decades of know‑how in the way operators cut, expand, and flatten metal with a rhythm that’s almost musical. This is where much of the world’s Expanded Metal Mesh begins its life.

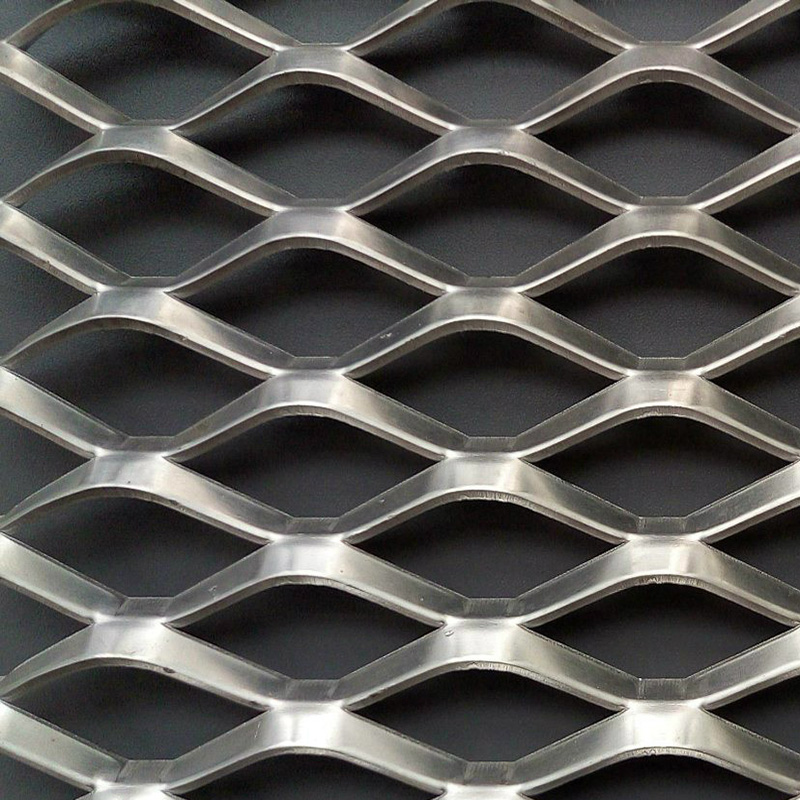

What it is (beyond the brochure)

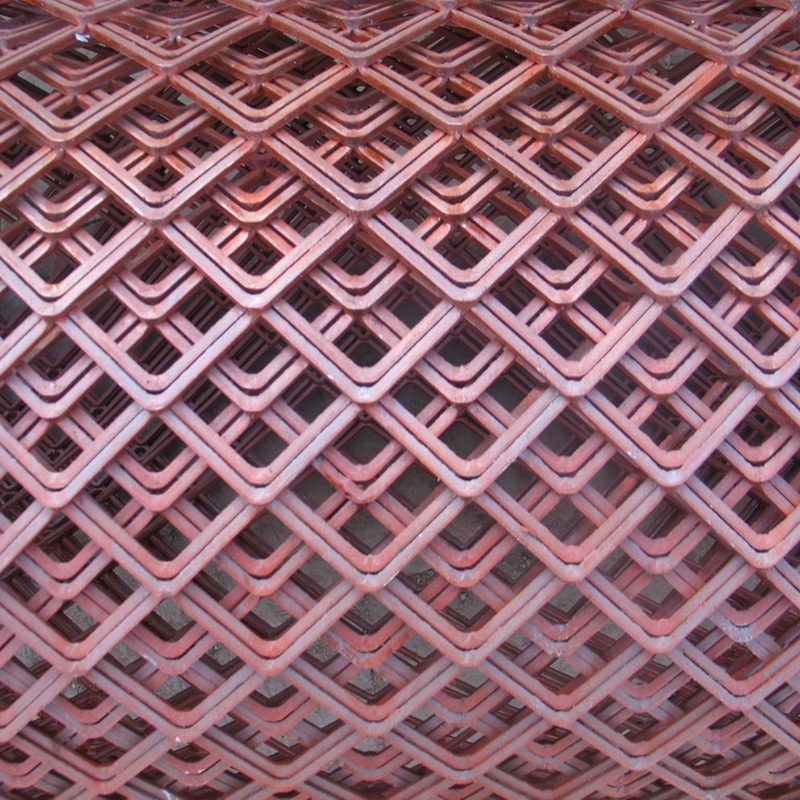

At its core, Expanded Metal Mesh is sheet metal slit and stretched to form diamond patterns (also hexagonal, round, triangle, even scale-like). No welding, less waste. Materials? Carbon steel, aluminum, stainless (304/316), nickel alloys — each with a vibe: strength, lightness, corrosion resistance, or high-temp stability.

Trend-wise, architects want bigger LWD for bold façades; oil and gas orders lean heavier, with hot-dip galvanizing. Data centers (surprisingly) ask for tighter SWD to balance airflow and security.

Quick specs that matter

| Parameter | Typical Range (≈, real‑world use may vary) |

|---|---|

| Base materials | Steel (Q195/Q235), Aluminum (3003/5052), Stainless (304/316), Nickel |

| Thickness | 0.5–8.0 mm |

| SWD / LWD | SWD ≈ 5–100 mm; LWD ≈ 10–200 mm |

| Strand width | ≈ 0.5–10 mm |

| Open area | ≈ 40–80% |

| Finishes | Black, pre‑galv, hot‑dip galvanizing, powder coat, anodizing (Al) |

| Standards touchpoints | ASTM F1267, EN 13658‑2 (lath), ASTM B117 / ISO 9227 (corrosion) |

From coil to panel: how it’s made

Expanded Metal Mesh production is a clean sequence: coil selection → slitting → expanding (press + diamond knives) → flattening (if needed) → cutting/forming → finishing (galv/anodize/powder) → QC. Factory testing I saw included aperture gauges, micrometers, load testing for walkways, and corrosion testing aligned with ASTM B117/ISO 9227 salt spray protocols.

Where it shines

- Industrial walkways, catwalks, platforms (OSHA-friendly grip, good drainage).

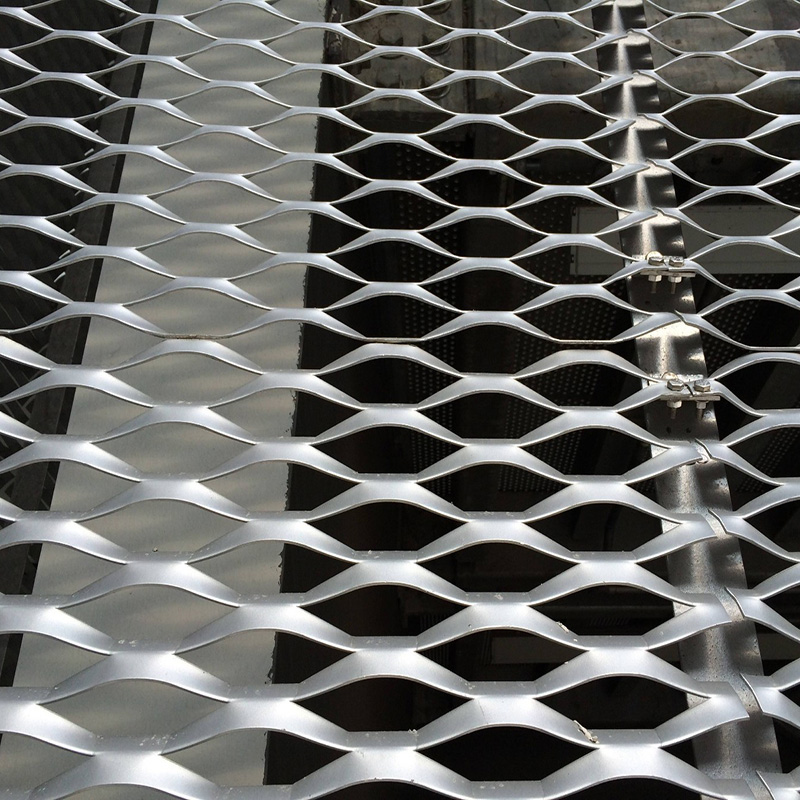

- Architectural façades, sunscreens, ceilings — quick way to add texture.

- Security fencing, machine guards, window protection, ventilation screens.

- Petrochemical reinforcement, filtration pre-layers, EMI-friendly enclosures.

Advantages? Non-slip, high strength-to-weight, seamless (no welds to crack), cut-to-shape flexibility. Many customers say aluminum brings the “wow” for façades; stainless is the low‑maintenance workhorse.

Mini case files

- Oil refinery, Gulf region: 4 mm steel, HDG, 70% open area. Reported 20% faster washdowns and zero slip incidents in 12 months.

- Retail mall façade, Europe: 3D‑formed aluminum, anodized bronze. Designer feedback: “light play at sunset is ridiculous — in a good way.”

- Data hall intake screens: stainless 316, tight SWD for airflow/security. Maintenance intervals extended from quarterly to semiannual.

Vendor snapshot (what buyers compare)

| Vendor | Strength | Lead time | Certs/Standards | Indicative price |

|---|---|---|---|---|

| Anping origin factory (this product) | Wide molds, custom SWD/LWD, tight QC | ≈ 7–18 days | ISO 9001; ASTM F1267 alignment; B117/ISO 9227 tests | Competitive |

| Import brand (EU) | Design finishes, anodizing depth | ≈ 3–6 weeks | CE for building lath; EN 13658‑2 | Higher |

| Low‑cost local | Fast spot orders | ≈ 3–10 days | Basic QC; spec variance risk | Lowest |

Customization and real-world durability

You can tweak SWD/LWD ratios, strand width, flattening, bends, frames, and coatings. For service life: HDG steel ≈ 15–25 yrs inland (5–10 coastal); powder coated steel ≈ 5–15 yrs; aluminum anodized ≈ 15–30 yrs; stainless 316 ≈ 20–50 yrs depending on pollutants. Salt spray results the factory shared: pre‑galv ≈ 120–240 h; HDG ≈ 480–720 h; powder over zinc ≈ 500–1,000 h (ASTM B117/ISO 9227).

A quick buying checklist

- Specify material, thickness, SWD/LWD, strand width, and finish.

- Reference standards (ASTM F1267; EN 13658‑2 where relevant).

- Ask for test data (B117/ISO 9227) and slip/load ratings for walkways.

- Confirm tolerances and visual samples — what looks “right” is subjective.

Origin: South Industrial Zone 07, Anping County, Hebei, China.

Authoritative citations

- ASTM F1267 — Standard Specification for Expanded Metal. https://www.astm.org/f1267

- ASTM B117 — Standard Practice for Operating Salt Spray (Fog) Apparatus. https://www.astm.org/b0117

- ISO 9227 — Corrosion tests in artificial atmospheres — Salt spray tests. https://www.iso.org/standard/63543.html

- EN 13658‑2 — Metal lath and beads for internal plastering. https://shop.bsigroup.com

- OSHA 29 CFR 1910 Subpart D — Walking‑Working Surfaces. https://www.osha.gov/laws-regs/regulations/standardnumber/1910

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025