-

+86 15030157877

-

sales@galvanizedmetalmesh.com

செப் . 23, 2024 04:24 Back to list

pvc coated welded mesh factories

PVC Coated Welded Mesh Factories An Overview

PVC (Polyvinyl Chloride) coated welded mesh has become a highly sought-after product in various industries, owing to its durability, versatility, and resistance to corrosion. This mesh is extensively used in applications ranging from agriculture to construction, and its production involves sophisticated manufacturing processes carried out in specialized factories.

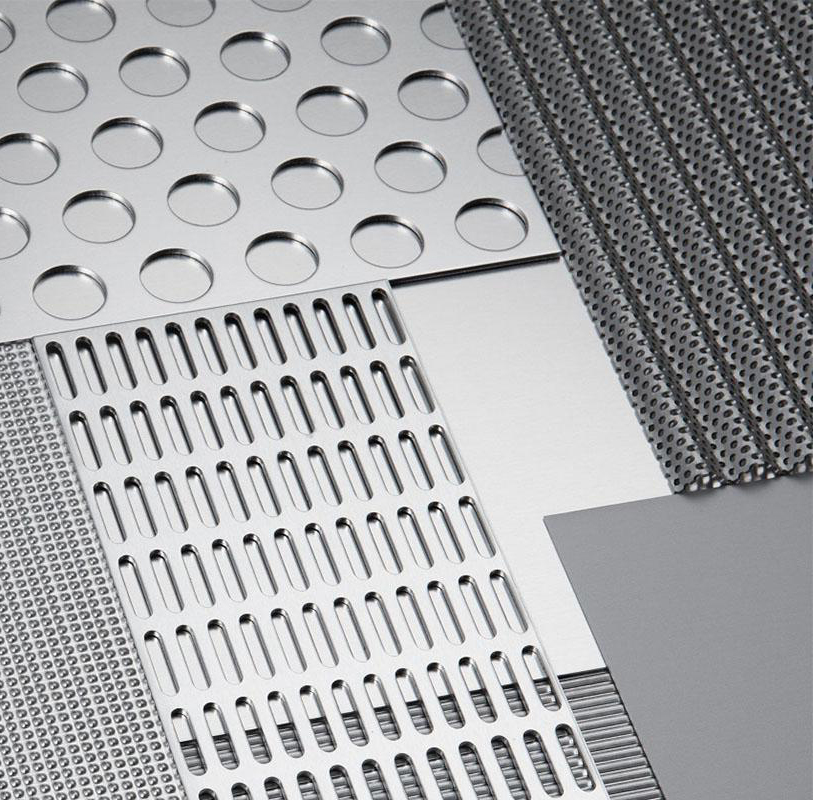

Understanding PVC Coated Welded Mesh

The PVC coated welded mesh consists of wires that are welded together at intersections, creating a strong grid-like structure. After the welding process, the mesh is coated in a layer of PVC, which enhances its protective qualities. This coating not only improves the mesh's aesthetic appeal but also offers additional protection against environmental elements, making it suitable for outdoor use.

Advantages of PVC Coated Welded Mesh

1. Durability The combination of welded steel and PVC coating provides exceptional tensile strength and longevity. This makes PVC coated welded mesh particularly advantageous in environments exposed to harsh weather conditions.

2. Corrosion Resistance The PVC layer acts as a barrier against humidity, chemicals, and other corrosive elements, significantly extending the lifespan of the mesh compared to its non-coated counterparts.

3. Variety of Applications This type of mesh is incredibly versatile. It is commonly used for fencing around farms, gardens, and construction sites. Additionally, it serves in various industrial applications such as partitioning spaces, safety barriers, and even animal enclosures.

pvc coated welded mesh factories

4. Aesthetic Appeal Available in a range of colors, PVC coated welded mesh can be aesthetically pleasing, allowing it to blend well with different environments while providing the necessary functionality.

The Manufacturing Process

The production of PVC coated welded mesh involves several critical steps. Initially, high-quality steel wires are drawn to the desired thickness. The wires are then cut and arranged into precise dimensions before being welded together at intersecting points. After the welding process, the mesh is treated to ensure a clean surface, followed by the application of PVC coating using either a dipping or spraying method.

Once the coating is applied, the mesh is cured in an oven to ensure proper adhesion and durability of the PVC layer. The final product undergoes rigorous quality control to ensure it meets industry standards in terms of strength, finish, and dimensional accuracy.

PVC Coated Welded Mesh Factories

Factories producing PVC coated welded mesh are typically equipped with modern machinery and technology to ensure efficiency and product quality. These facilities employ skilled workers who are trained in both the operating machinery and ensuring adherence to safety standards. With the increasing demand for this product worldwide, many factories are expanding their production capabilities, investing in automation, and developing innovative techniques to enhance product performance.

In conclusion, PVC coated welded mesh has established itself as a vital product across various sectors. The combination of strength, corrosion resistance, and visual appeal makes it an optimal choice for many applications. As the market continues to grow, so too does the importance of specialized factories dedicated to the production of this indispensable material. These factories not only contribute to local economies but also play a crucial role in supporting global industries that rely on quality mesh solutions.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025