-

+86 15030157877

-

sales@galvanizedmetalmesh.com

நவ் . 20, 2024 21:41 Back to list

razor wire galvanized factories

The Importance of Galvanized Razor Wire Factories in Enhancing Security

In today's world where security concerns are paramount, the demand for effective fencing solutions continues to rise. Among the various options available, galvanized razor wire stands out for its effectiveness and durability. A pivotal role in the supply chain of this product is played by factories specializing in the production of galvanized razor wire. The intricate processes involved in manufacturing this security measure not only contribute to its efficiency but also ensure that it meets the diverse needs of various sectors, including residential, commercial, and industrial spaces.

Understanding Galvanized Razor Wire

Galvanized razor wire is a type of fencing that consists of sharp blades or barbs attached to a wire strand. The galvanization process involves coating the wire with a layer of zinc, which serves as a protective barrier against rust and corrosion. This treatment is essential for prolonging the lifespan of the wire, especially in outdoor settings where exposure to weather conditions can be a significant factor.

The design of razor wire is intrinsically intimidating, making it an effective deterrent against intruders. The sharp edges and pointed tips not only serve as a physical barrier but also project an image of security and vigilance. This psychological aspect is just as crucial as the physical barrier it provides.

The Manufacturing Process

The production of galvanized razor wire is a complex process that involves several steps to ensure quality and durability. Factories engaged in this manufacturing process typically follow these stages

2. Wire Drawing The selected steel is then drawn into wires of desired thicknesses. This process increases the strength of the wire and prepares it for further treatment.

3. Blade Formation During this step, the razor blades are created. This is usually accomplished by slicing thin strips of metal into sharp blades that will be attached to the wire.

razor wire galvanized factories

4. Galvanization The drawn and shaped wire undergoes galvanization. In this process, the wire is submerged in molten zinc, which provides a robust anti-corrosive coating. This step is crucial in ensuring the longevity of the razor wire.

5. Coiling and Packaging After galvanization, the razor wire is coiled and packaged for shipping. Quality checks are conducted throughout the process to ensure that the final product meets safety and performance standards.

The Role of Factories

Galvanized razor wire factories are essential not only for producing these products but also for maintaining high standards of safety and quality. Skilled labor, advanced technology, and strict quality control measures are vital for the successful operation of these factories. Moreover, manufacturers must adhere to regulations and industry standards, such as those set by safety organizations, to ensure that their products are reliable and effective.

These factories also play a significant role in research and development, innovating new designs and applying advanced materials to enhance the functionality of the wire. Continuous improvement leads to better performance characteristics, making galvanized razor wire a superior choice for security fencing.

Market Demand and Applications

The demand for galvanized razor wire is significant across various sectors. Security firms, construction companies, and government agencies often require robust security measures for vulnerable sites. Factories producing galvanized razor wire cater to this need by offering products tailored for specific applications, such as prison facilities, military bases, airports, and even high-security residential areas.

The rise in urban crime rates and increased focus on perimeter security have further fueled the market's growth. As businesses and residential areas seek advanced security solutions, galvanized razor wire remains a preferred choice due to its affordability, effectiveness, and enduring nature against environmental challenges.

Conclusion

In conclusion, galvanized razor wire factories play a vital role in enhancing and securing our environments. Their ability to produce high-quality, durable products contributes significantly to the nationwide effort to improve security and safety. As security concerns grow, the importance of these factories will only increase, ensuring that galvanized razor wire remains a critical component of modern security solutions.

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

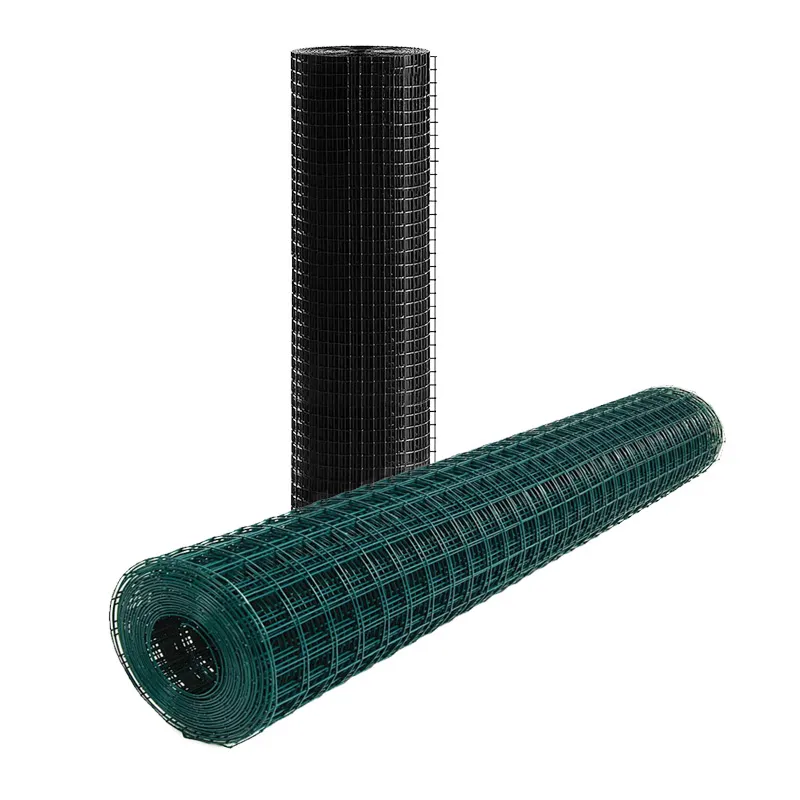

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025