-

+86 15030157877

-

sales@galvanizedmetalmesh.com

நவ் . 30, 2024 09:01 Back to list

Square Wire Mesh Manufacturer for Versatile Industrial Applications and Custom Solutions

Exploring the World of Square Wire Mesh Insights from the Factory

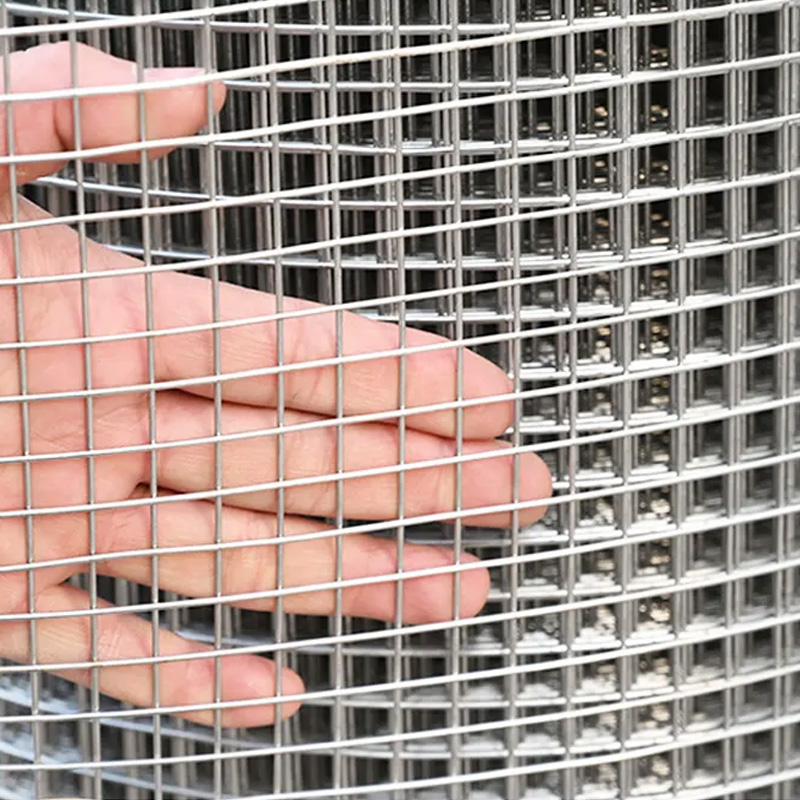

In the realm of construction and manufacturing, square wire mesh plays a pivotal role in a variety of applications. Whether used for fencing, reinforcement in concrete, or as a component in industrial machinery, the versatility of square wire mesh makes it a staple in numerous industries. A thorough understanding of the processes involved in its production, alongside the unique properties that contribute to its functionality, is essential for anyone interested in this specialized field.

The Production Process

At the heart of square wire mesh manufacturing lies a sophisticated factory setup equipped with advanced machinery. The journey begins with the selection of raw materials. Typically, high-quality steel wire is chosen for its strength and durability. The wire is then drawn into various gauges, corresponding to the desired specifications of the final mesh product.

Once the wire reaches the appropriate gauge, it undergoes a weaving process. This is where the magic happens. The wires are meticulously woven together in a square pattern, yielding the characteristic shape that gives the product its name. Modern factories employ automated weaving machines, which enhance precision and consistency while reducing production time. Skilled operators monitor the machinery to ensure that each roll of mesh meets the stringent quality standards set by the industry.

After weaving, the mesh is subjected to several finishing processes. These can include galvanizing, where a protective zinc coating is applied to prevent rusting and corrosion, or powder coating for aesthetic appeal and additional protection. The choice of finish depends on the intended use of the mesh, ensuring that it can withstand the rigors of its environment.

Applications of Square Wire Mesh

square wire mesh factory

The applications of square wire mesh are vast, spanning multiple sectors. In construction, it is often used as reinforcement in concrete structures, providing additional strength and stability. For fencing purposes, square wire mesh offers an effective solution, balancing visibility with security. Its adaptability allows it to be utilized in various settings, from agricultural fencing to residential backyards.

In industrial contexts, square wire mesh serves essential roles in filtration systems, machinery guards, and conveyor belts. Its ability to allow airflow and visibility while maintaining structural integrity makes it a preferred choice in manufacturing environments. Furthermore, hobbyists and DIY enthusiasts often find square wire mesh useful for crafting, gardening projects, and pet enclosures.

Quality Control and Safety Standards

A reputable square wire mesh factory adheres to strict quality control measures. This includes regular inspections throughout the manufacturing process, ensuring that each piece of mesh meets the required specifications. Factories often have certifications such as ISO 9001, which demonstrates commitment to quality management systems.

Safety is also a paramount concern in the production of square wire mesh. Factories implement safety protocols to protect workers, including the use of personal protective equipment (PPE) and regular safety training. Additionally, the materials used in production are evaluated for compliance with environmental standards, ensuring that the factory operates sustainably.

Conclusion

The world of square wire mesh manufacturing is a blend of technology, craftsmanship, and innovation. From the selection of raw materials to the intricacies of weaving and finishing, each step is crucial to producing a high-quality product that meets diverse needs. As industries continue to evolve, the demand for reliable and versatile materials like square wire mesh is only expected to grow. The factory itself, functioning as a hub of activity and ingenuity, plays an essential role in shaping the future of construction and manufacturing. With ongoing advancements in production techniques and materials, square wire mesh is poised to remain a key player in various applications for years to come.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025