-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜன . 06, 2025 11:19 Back to list

steel wire mesh

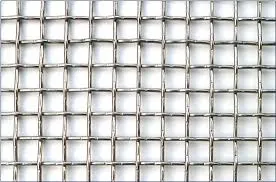

Steel wire mesh has long been a cornerstone in the construction and manufacturing industries, known for its strength, versatility, and cost-effectiveness. However, its applications go beyond these basic characteristics, with its use expanding into areas that reflect the growth of modern architectural and industrial demands.

In projects requiring reinforced strength, such as the construction of highways, bridges, or high-rise buildings, the use of steel wire mesh becomes indispensable. Its high tensile strength and flexibility allow it to absorb impact and handle structural stresses with ease. This ensures that constructions maintain their integrity over time, even when subjected to heavy loads or harsh environmental conditions. Contractors prefer this material not only for its functional benefits but also for the significant cost savings in labor and material that it allows by reducing the need for thick, costly concrete reinforcements.

Moreover, the utility of steel wire mesh extends into the sustainability sector. As industries are increasingly driven by the need for environmentally friendly solutions, steel wire mesh stands out. Made from recyclable materials, it can be repurposed at the end of its life cycle, aligning with the global shift towards reducing industrial waste. This sustainable aspect of steel wire mesh makes it a favored choice for green building projects seeking LEED certification or similar environmental standards.

In the agricultural sector, steel wire mesh provides unparalleled benefits in constructing animal cages, fencing, and crop protection structures. Its durability in diverse weather conditions ensures that it offers long-term solutions with minimal maintenance. Farmers and agricultural businesses appreciate its reliability and the protection it affords in safeguarding livestock and crops from pests and predators.

Architects and designers are unlocking new horizons for steel wire mesh, incorporating it into their designs to add aesthetic value and functionality. Its use in creating facade claddings, partition walls, and ceilings showcases the material’s ability to transform spaces with modernist and industrial appeal. The play of natural light through its open mesh structure creates visually fascinating patterns, enhancing interior and exterior designs without compromising on security and privacy.

steel wire mesh

Another innovative use of steel wire mesh is in the filtration and separation processes across various industries. Its excellent adaptability to different environments allows it to filter air, liquids, and gases efficiently. This trait is crucial in industries like pharmaceuticals, petrochemicals, and food and beverage, where maintaining purity and safety standards is of paramount importance.

The expertise in selecting and installing steel wire mesh cannot be overstated. It requires an understanding of the specific needs of a project and the types of mesh available, including welded, woven, and knitted variants. Each type offers specific benefits, making the choice critical depending on the application. Authorities and specialists in the field are entrusted with ensuring these selections meet project specifications and safety regulations, reflecting the authoritative role that consultants and engineers play in this domain.

Steel wire mesh’s trustworthiness as a preferred material can be largely attributed to rigorous manufacturing processes and strict quality controls that comply with international standardizations. This consistent reliability reduces the risk of project delays and failures, inspiring confidence among investors, developers, and end-users alike.

In conclusion, the multifaceted applications and inherent benefits of steel wire mesh underscore its indispensable role in contemporary industry and architecture. Its contribution towards creating robust, sustainable, and aesthetically pleasing structures speaks to its enduring relevance and pioneering future. As industries continue to evolve, steel wire mesh stands ready to meet new challenges with the same efficiency and reliability that have secured its place as a vital building and manufacturing component.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025