-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜன . 09, 2025 12:20 Back to list

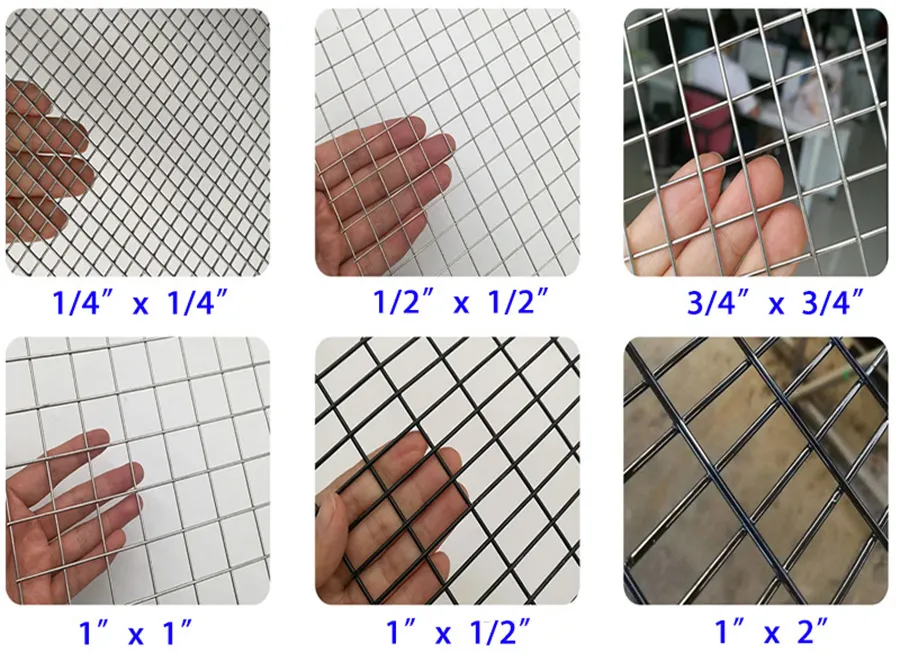

galvanized welded wire mesh

Welded wire mesh stands as a cornerstone within the spectrum of construction and industrial applications, primarily due to its durability, versatility, and robust structure. As a seasoned professional in the field, one can attest to its multifaceted applications that go beyond the conventional uses, driving efficiency and reinforcing structural integrity in projects worldwide.

In terms of installation, welded wire mesh is praised for its simplicity. Its pre-fabricated nature saves time and labor during assembly, as it can be easily adjusted or reshaped on-site with standard tools. This feature is particularly advantageous in time-sensitive projects where efficiency is key, and any delay could potentially inflate costs and resource allocation. Beyond construction, the agricultural sector has embraced welded wire mesh for various uses such as animal fencing and plant protection, where its ability to create secure and stable enclosures ensures the welfare of livestock and crops. These users often highlight the mesh’s durability and the ease with which it can be relocated or repurposed as pivotal to ongoing agricultural sustainability. Trust in welded wire mesh also stems from rigorous testing and compliance with industry standards, which reinforce its credibility. Manufacturers subject these materials to stringent quality control processes to ensure each piece meets precise specifications, reassuring users of their dependability. This attention to quality and detail establishes welded wire mesh as not only a choice of necessity but of judicious investment in any project demanding durability and resilience. In summary, welded wire mesh embodies the intersection of form, function, and flexibility. Its application across various fields underscores an enduring legacy of solving structural challenges with grace and reliability. For those in pursuit of excellence in construction and beyond, welded wire mesh remains an unassailable ally, merging expertise with innovation to achieve and indeed surpass anticipated outcomes.

In terms of installation, welded wire mesh is praised for its simplicity. Its pre-fabricated nature saves time and labor during assembly, as it can be easily adjusted or reshaped on-site with standard tools. This feature is particularly advantageous in time-sensitive projects where efficiency is key, and any delay could potentially inflate costs and resource allocation. Beyond construction, the agricultural sector has embraced welded wire mesh for various uses such as animal fencing and plant protection, where its ability to create secure and stable enclosures ensures the welfare of livestock and crops. These users often highlight the mesh’s durability and the ease with which it can be relocated or repurposed as pivotal to ongoing agricultural sustainability. Trust in welded wire mesh also stems from rigorous testing and compliance with industry standards, which reinforce its credibility. Manufacturers subject these materials to stringent quality control processes to ensure each piece meets precise specifications, reassuring users of their dependability. This attention to quality and detail establishes welded wire mesh as not only a choice of necessity but of judicious investment in any project demanding durability and resilience. In summary, welded wire mesh embodies the intersection of form, function, and flexibility. Its application across various fields underscores an enduring legacy of solving structural challenges with grace and reliability. For those in pursuit of excellence in construction and beyond, welded wire mesh remains an unassailable ally, merging expertise with innovation to achieve and indeed surpass anticipated outcomes.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025