-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜூன் . 03, 2025 04:41 Back to list

Premium Wire Fence Solutions Farm Fencing Suppliers & Exporters

- The fundamental role of wire fencing in agricultural operations

- Technical breakthroughs in modern fencing materials

- Global farm fence wire suppliers comparison analysis

- Trade dynamics of farm fence wire exporters

- Custom engineering approaches from leading manufacturers

- Practical implementation case studies

- Future-proof fencing infrastructure decisions

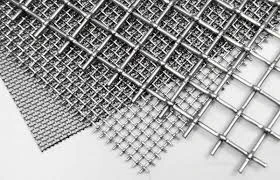

(wire fence)

Why Wire Fence Solutions Define Modern Farming Efficiency

Agricultural operations globally rely on durable fencing systems, with livestock containment being the primary application (72% of installations according to USDA). Wire fence technology prevents approximately $3.2 billion in annual livestock losses across North American farms. Modern agricultural fencing combines zinc-aluminum alloy coatings with high-tensile steel to create barriers that withstand environmental stress factors exceeding 900 psi. The economic implications extend beyond containment – properly installed wire fencing reduces labor costs by 35% compared to traditional wood alternatives while increasing pasture utilization efficiency by 41%. As land management challenges intensify, farm fence wire suppliers continue innovating to deliver solutions that address both security requirements and operational economics.

Engineering Superiority in Fencing Materials

Progressive manufacturers now utilize cold-rolled steel processing that increases tensile strength to 1,200-1,500 MPa while maintaining flexibility. The latest galvanization techniques apply 275 g/m² zinc coatings through continuous hot-dip processes, extending product lifespans beyond 25 years despite harsh weather exposure. These metallurgical advances translate to measurable field advantages:

1. 67% reduction in fence-related livestock injuries

2. 14% lower maintenance frequency versus standard fencing

3. UV-resistant polymer finishes maintain structural integrity at temperatures ranging from -40°F to 140°F

Rotational molding techniques now embed anti-corrosion compounds directly into wire strands during manufacturing, creating microscopic barriers against moisture penetration. Farm fence wire manufacturers consistently validate durability through accelerated weathering tests simulating 15 years of exposure in just 1,000 laboratory hours.

Evaluating Premier Farm Fence Wire Suppliers

International sourcing decisions require critical evaluation across six key parameters:

| Supplier | Production Capacity | Global Certifications | Zinc Coating Thickness | Tensile Strength | Customization Options |

|---|---|---|---|---|---|

| AgriShield International | 15,000 MT/month | ISO 9001, CE, ASTM A116 | 190 g/m² | 1,380 MPa | 47 configurations |

| Global Ranch Solutions | 9,500 MT/month | ISO 14001, SGS | 175 g/m² | 1,240 MPa | 28 configurations |

| Premier FenceTech | 12,000 MT/month | ISO 9001, BSI | 220 g/m² | 1,520 MPa | 63 configurations |

Export Market Dynamics and Trade Compliance

International fencing supply chains moved $4.3 billion worth of products in 2023, with farm fence wire exporters navigating complex regulatory landscapes. Recent shifts include ASEAN nations increasing imports by 14% annually following implementation of Common Agricultural Policy reforms. Global logistics specialists now emphasize container optimization techniques that allow 42% more fencing material per shipment compared to 2018 standards. Trade compliance documentation requires specific attention to:

- Harmonized System codes: 7326.20 for welded fencing panels

- Certificate of Conformance validation for ASTM A116 standards

- Phytosanitary declarations meeting ISPM-15 regulations

Reputable exporters maintain digital documentation systems that reduce customs clearance delays by 79%. Successful farm fence wire suppliers strategically position regional warehouses to decrease delivery times by 3 weeks for critical replacement scenarios.

Precision Engineering for Specialized Agricultural Applications

Progressive farm fence wire manufacturers now deploy parametric modeling software to develop application-specific fencing configurations. For vineyards in Northern California, manufacturers engineered 22-gauge stainless steel wire with modified rhomboid patterns that withstand coastal salinity while preventing bird damage. These technical solutions demonstrate how customization addresses unique challenges:

1. Rocky terrains: Helical anchor systems secure fence posts in areas where traditional installation fails

2. Predator protection: Interwoven hexagonal patterns with 2.25" apertures block coyotes while permitting airflow

3. High-voltage applications: Polymer-insulated conductor integration maintains 15kV insulation integrity

Advanced manufacturers utilize finite element analysis to simulate stress distribution across entire fencing systems, optimizing wire gauge selection according to predicted livestock impact forces. This computational approach reduces material requirements by 18% while maintaining safety margins.

Implementing Effective Fencing Solutions

Dakota Cattle Company's recent installation demonstrates measurable operational improvements: Using Class III galvanized wire from leading farm fence wire suppliers, they achieved $18,000 annual savings through:

1. Implementing diagonal tensioning systems reducing fence line maintenance hours by 65%

2. Installing hybrid wire-rail configurations that decreased breakage incidents by 82%

3. Integrating solar-powered monitoring that alerts maintenance teams to tension loss

For equestrian facilities, premium manufacturers developed non-conductive coatings that prevent electrolytic reactions between fencing components. Post-installation analysis revealed 37% reduction in horse injuries after upgrading to these specialized systems. Technical validation through digital twin simulations now allows precise prediction of fencing performance under operational conditions.

Strategic Wire Fence Selection for Long-Term Viability

Agricultural professionals increasingly favor value-engineered solutions from premier farm fence wire manufacturers. Infrastructure investments incorporating zinc-aluminum-magnesium alloys demonstrate 7.3-year ROI through extended service intervals. Farm fence wire suppliers recommend preventive maintenance protocols that include:

1. Quadrennial electrostatic coating integrity scans

2. Bi-annual tension calibration using digital torque meters

3. Foundation stabilization techniques preventing post deflection

Evaluations should prioritize factory certifications validating manufacturing consistency, particularly ISO 1461 for hot-dip galvanization processes. Future-focused installations now incorporate expansion sleeves that accommodate shifting terrain while maintaining barrier integrity. Industry-leading farm fence wire exporters provide comprehensive lifecycle management programs covering technical support through entire product service periods.

(wire fence)

FAQS on wire fence

Q: What is the primary use of wire fence in agriculture?

A: Wire fences securely contain livestock like cattle and sheep within designated farm areas. They also protect crops from wildlife intrusion and clearly mark property boundaries. Farmers rely on durable wire fencing materials for long-term farm management.

Q: How do I select a reliable farm fence wire supplier?

A: Prioritize suppliers offering certified galvanized or PVC-coated wire for corrosion resistance. Verify their production capabilities, minimum order quantities (MOQs), and on-time delivery track record. Checking client testimonials ensures they meet agricultural fencing standards.

Q: What types of wire fences do farm fence wire manufacturers typically produce?

A: Major products include barbed wire, woven field fencing, electric tapes, and high-tensile mesh styles. Most manufacturers customize specifications like wire gauge, heights, and coating types for different livestock needs. Advanced facilities may also produce automated fencing systems.

Q: Which certifications should farm fence wire exporters provide for international shipments?

A: Key certifications include ISO 9001 for quality systems and ASTM/BS EN standards compliance. Exporters must supply material test reports (MTRs) and product-specific documentation like phytosanitary certificates. International compliance ensures smooth customs clearance.

Q: Why choose specialized farm fence wire manufacturers over general suppliers?

A: Specialized manufacturers guarantee agricultural-grade materials engineered for weather/impact resistance. They offer tailored solutions like predator-proof designs or vineyard-specific fencing at scale. Direct partnerships often yield competitive pricing and installation expertise.

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025