-

+86 15030157877

-

sales@galvanizedmetalmesh.com

பிப் . 01, 2025 03:33 Back to list

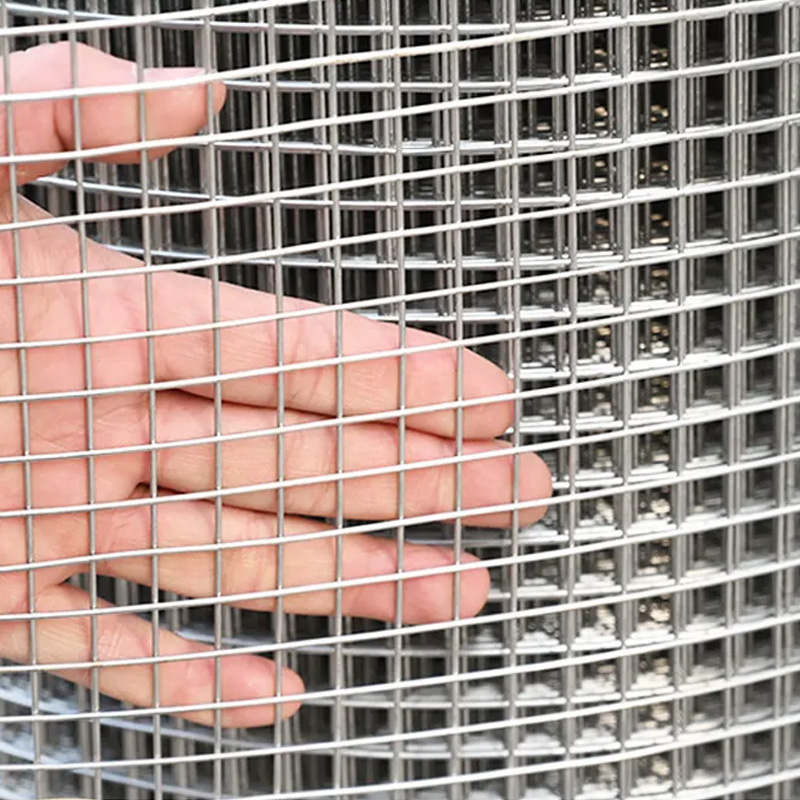

galvanized welded wire mesh

In the realm of modern construction, wire mesh for concrete stands as an unsung hero. This robust material, though humble in appearance, plays a crucial role in enhancing the durability and integrity of concrete structures. With years of industry experience and extensive expertise in construction materials, I've witnessed first-hand the transformative impact of wire mesh in a variety of applications, reaffirming its status as an essential component in construction projects worldwide.

Among the most compelling advantages of wire mesh for concrete is its eco-friendliness. In a world increasingly conscious of sustainable building practices, wire mesh is often crafted from recycled materials, helping reduce the carbon footprint of construction projects. Furthermore, its durability aids in prolonging the lifespan of concrete structures, minimizing the need for extensive repairs and additional resource consumption. In the field of construction, the choice of materials significantly impacts the longevity and safety of a project. Seasoned professionals understand that opting for wire mesh not only enhances structural performance but also promises peace of mind. The empirical evidence and tested performance metrics of wire mesh solidify its reputation as a cornerstone of modern construction, blending traditional reinforcement strategies with contemporary demands for sustainability and efficiency. Innovations in the manufacturing processes of wire mesh continue to push the boundaries of what is possible, making it more adaptable to custom specifications and project requirements. As technology advances, so does the potential for wire mesh to meet increasingly complex engineering challenges, ensuring its relevancy and superior performance in future endeavors. In conclusion, wire mesh for concrete remains a vital material in the construction industry. Its proven expertise in reinforcing concrete, authority in meeting environmental and engineering standards, and unwavering trustworthiness as a dependable material make it a top choice for ensuring the safety and stability of construction projects. Whether for residential, commercial, or industrial applications, the integration of wire mesh into concrete structures is a testament to a commitment to building with strength, precision, and sustainability.

Among the most compelling advantages of wire mesh for concrete is its eco-friendliness. In a world increasingly conscious of sustainable building practices, wire mesh is often crafted from recycled materials, helping reduce the carbon footprint of construction projects. Furthermore, its durability aids in prolonging the lifespan of concrete structures, minimizing the need for extensive repairs and additional resource consumption. In the field of construction, the choice of materials significantly impacts the longevity and safety of a project. Seasoned professionals understand that opting for wire mesh not only enhances structural performance but also promises peace of mind. The empirical evidence and tested performance metrics of wire mesh solidify its reputation as a cornerstone of modern construction, blending traditional reinforcement strategies with contemporary demands for sustainability and efficiency. Innovations in the manufacturing processes of wire mesh continue to push the boundaries of what is possible, making it more adaptable to custom specifications and project requirements. As technology advances, so does the potential for wire mesh to meet increasingly complex engineering challenges, ensuring its relevancy and superior performance in future endeavors. In conclusion, wire mesh for concrete remains a vital material in the construction industry. Its proven expertise in reinforcing concrete, authority in meeting environmental and engineering standards, and unwavering trustworthiness as a dependable material make it a top choice for ensuring the safety and stability of construction projects. Whether for residential, commercial, or industrial applications, the integration of wire mesh into concrete structures is a testament to a commitment to building with strength, precision, and sustainability.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025