-

+86 15030157877

-

sales@galvanizedmetalmesh.com

டிசம்பர் . 10, 2024 15:34 Back to list

Top Wire Mesh Panel Manufacturers for Quality and Durability Solutions

The Rise of Wire Mesh Panels A Closer Look at Manufacturers and Their Impact on Various Industries

Wire mesh panels, often overlooked, play a crucial role in various sectors, including construction, agriculture, and industrial applications. As demand for these versatile materials rises, manufacturers have adapted to changing market requirements, leading to innovations that enhance both functionality and design. This article delves into the significance of wire mesh panels, the processes involved in their production, and the key players in the manufacturing sector.

Understanding Wire Mesh Panels

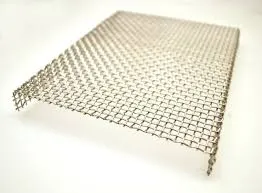

Wire mesh panels are primarily composed of interwoven wires, creating a grid-like structure that can be made from several materials, including stainless steel, galvanized steel, and aluminum. These panels are renowned for their strength, durability, and corrosion resistance, making them suitable for a wide range of applications.

In the construction industry, wire mesh panels are commonly used for reinforcement in concrete, as protective barriers, and as fencing solutions. Their open design facilitates airflow and visibility, making them ideal for use in livestock enclosures and security applications. Moreover, in the industrial sector, they are utilized in filtration systems, shelves, and storage solutions.

The Manufacturing Process

The manufacturing of wire mesh panels involves a series of sophisticated processes to ensure that the products meet industry standards. It begins with the selection of raw materials, which are chosen based on the specific needs of the application. Manufacturers typically use high-quality wire that can withstand environmental and mechanical stresses.

After sourcing the raw materials, the wires are drawn to the required thickness. Subsequently, they undergo a mesh weaving process, which can be executed using various methods such as welding, weaving, or knitting. The choice of method often depends on the intended application of the mesh panels and the desired strength.

Once the panels are crafted, they undergo several treatments, including galvanization or coating, to enhance their resistance to rust and corrosion. Quality control measures are paramount during production, ensuring that each panel meets the necessary specifications and standards.

Key Manufacturers and Innovations

wire mesh panels manufacturers

As the market for wire mesh panels grows, numerous manufacturers have established themselves as leaders in the field. Companies such as WireCrafters, IWS (Industrial Wire Solutions), and Davis Wire have pioneered various innovations, contributing to the efficiency and effectiveness of wire mesh products.

These manufacturers have embraced technology, incorporating automated machinery that streamlines production processes and improves precision. Furthermore, advanced design software allows for customized solutions, enabling clients to request specific sizes, shapes, and wire configurations.

Sustainability has also become a focal point for many wire mesh panel manufacturers. With growing awareness around environmental impact, companies are investing in eco-friendly materials and processes, such as utilizing recycled metals and adopting energy-efficient manufacturing techniques. This commitment to sustainability not only enhances their brand reputation but also meets the expectations of environmentally conscious consumers.

Applications in Various Industries

The applications of wire mesh panels are vast and varied. In the construction industry, they are essential for creating safe and durable structures. Their use in concrete reinforcement enhances the longevity of structures, while their versatility allows for creative architectural designs.

In agriculture, wire mesh panels are invaluable for fencing livestock and securing crops. They offer a cost-effective solution for protecting animals while allowing for visibility and ventilation.

In industrial settings, wire mesh panels are utilized in filtration systems, enabling efficient separation processes and ensuring the purity of products. Their strength also makes them ideal for storage solutions, maximizing space without compromising on safety.

Conclusion

Wire mesh panels may not always be at the forefront of industrial discussions, but their importance cannot be overstated. With manufacturers continuously innovating and adapting to market needs, these panels are set to play an even more critical role in diverse industries. As we move toward a more sustainable future, the development and production of wire mesh panels will likely remain a key area for growth and innovation. Whether in construction, agriculture, or industry, wire mesh panels will continue to support and enhance our built environment, proving their enduring value across time and sectors.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025