-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ต.ค. . 31, 2024 14:59 Back to list

Fiber-Reinforced Welded Wire Mesh Manufacturing Facilities and Their Benefits

The Importance of Concrete Welded Wire Mesh in Construction

Concrete welded wire mesh has become an essential component in modern construction practices, playing a pivotal role in reinforcing concrete structures. As urbanization continues to expand and infrastructure demands grow, the importance of reliable and durable materials, like welded wire mesh, cannot be overstated. This article will explore the features, benefits, and significance of welded wire mesh, particularly focusing on factories that specialize in its production.

The Importance of Concrete Welded Wire Mesh in Construction

One of the primary benefits of using welded wire mesh in concrete is its ability to enhance structural integrity. When embedded in concrete, the mesh helps distribute loads evenly, reducing the risk of cracking and ensuring the durability of the structure. This is particularly crucial in areas subjected to heavy loads, such as roads, bridges, and commercial buildings. Additionally, the presence of welded wire mesh provides flexural strength, allowing concrete structures to withstand stress and strain effectively.

concrete welded wire mesh factories

Another significant advantage is the ease of installation. Welded wire mesh comes pre-manufactured in sheets or rolls, making it easier for contractors to handle and position during the construction phase. This not only speeds up the installation process but also minimizes labor costs, providing an efficient solution for builders. The uniformity of the mesh ensures that it fits consistently within the concrete formwork, leading to high-quality finished products.

Environmental considerations also play a role in the adoption of welded wire mesh. Factories that produce this material are increasingly focusing on sustainable practices, including using recycled materials and implementing energy-efficient manufacturing processes. As the industry shifts towards greener building practices, welded wire mesh stands out as a material that aligns with these goals, reducing waste and the carbon footprint of construction projects.

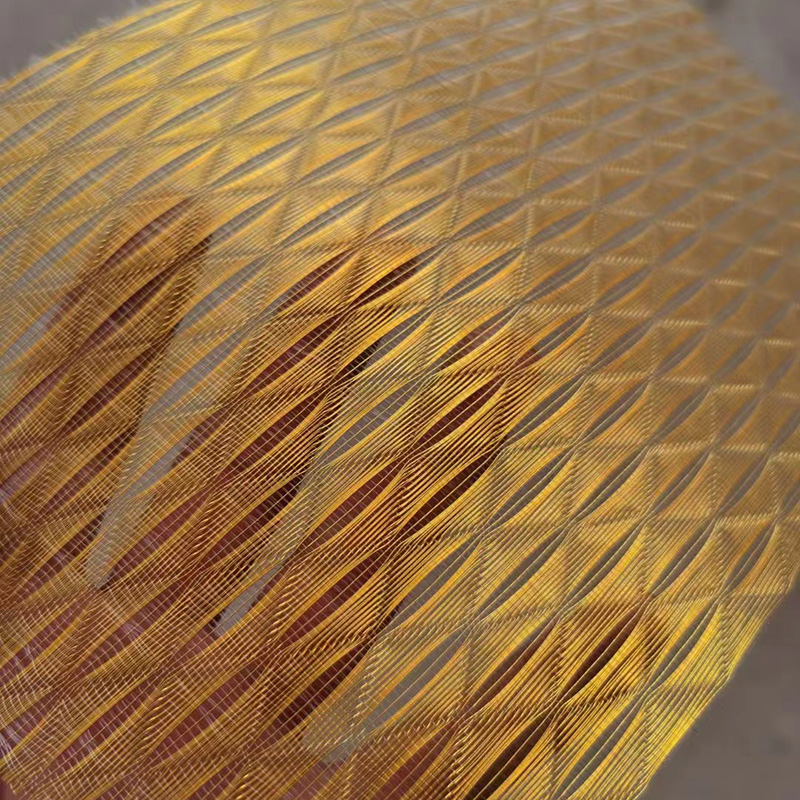

In addition, the versatility of welded wire mesh makes it suitable for a myriad of applications beyond traditional structural reinforcement. It is increasingly being used in decorative applications, such as fencing, landscape designs, and even artistic installations. As the demand for innovative construction solutions grows, welded wire mesh factories are continually evolving their offerings to meet the diverse needs of the market.

In conclusion, concrete welded wire mesh serves as a critical element in the construction industry, providing strength, durability, and efficiency. The factories that manufacture this product are at the forefront of innovation, ensuring that builders have access to high-quality materials that meet modern construction demands. As the construction landscape continues to evolve, the role of welded wire mesh will undoubtedly expand, signaling its importance in both current and future building practices.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025