-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ส.ค. . 15, 2025 01:20 Back to list

Custom Square Wire Mesh - High Quality, Wholesale Supply

Understanding Square Wire Mesh: Industry Trends and Essential Applications

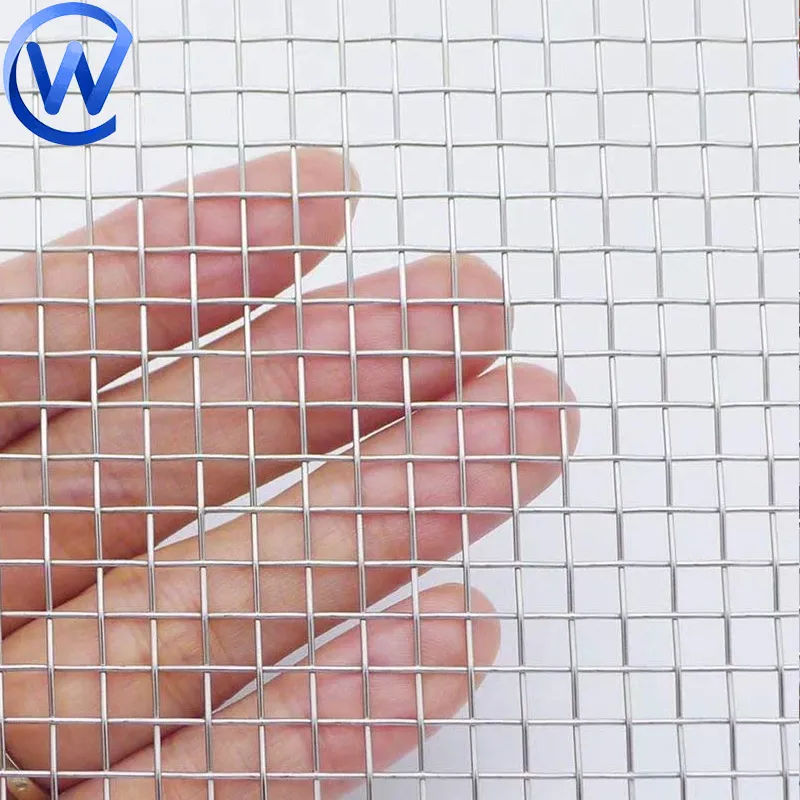

Square wire mesh is a fundamental component in countless industrial and commercial applications, renowned for its uniform openings, strength, and versatility. The global demand for this material continues to grow, driven by burgeoning infrastructure projects, an increasing need for robust filtration solutions, and expansion in sectors like construction, agriculture, and manufacturing. Current industry trends emphasize the development of high-performance alloys for enhanced corrosion resistance, improved production efficiency to meet bulk demand for wholesale square wire mesh, and stringent quality control measures to ensure product reliability. Manufacturers are also focusing on sustainable production practices, utilizing recycled materials and energy-efficient processes to meet environmental compliance standards.

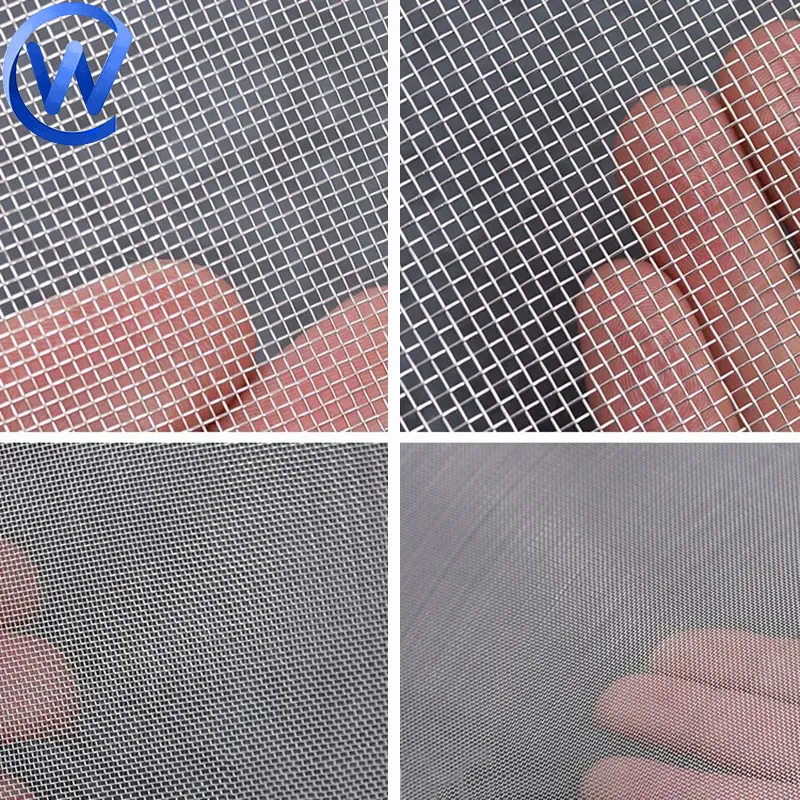

The market is witnessing a shift towards customized solutions, as industries require specific mesh sizes, wire diameters, and material compositions to optimize performance in unique operational environments. This has led to a greater emphasis on the capabilities of custom square wire mesh manufacturers. Furthermore, advancements in weaving and welding technologies allow for the creation of meshes with unprecedented precision, catering to highly specialized filtration and separation tasks. Understanding these dynamics is crucial for businesses seeking reliable and efficient material solutions in a competitive global landscape.

The Precision Behind Square Wire Mesh Manufacturing: A Comprehensive Process

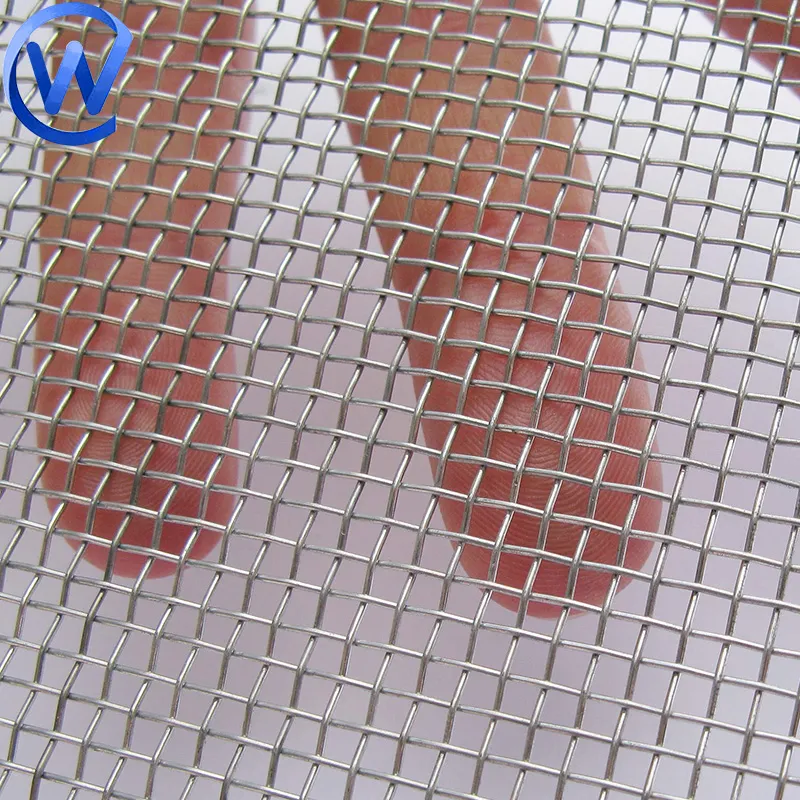

The production of high quality square wire mesh is a sophisticated process that begins with the careful selection of raw materials. Common materials include stainless steel (SS304, SS316, SS316L), galvanized iron, low carbon steel, and various non-ferrous metals like copper or brass, chosen based on the intended application's demands for corrosion resistance, strength, and conductivity. The primary manufacturing process involves either weaving or welding, each offering distinct advantages. Woven mesh, produced on specialized looms, interlaces warp and weft wires to create stable, precise openings, suitable for fine filtration. Welded mesh, on the other hand, involves resistance welding of wires at each intersection, providing exceptional rigidity and strength, ideal for structural applications or heavy-duty screening.

Post-production, critical quality control measures are implemented to ensure adherence to international standards such as ISO 9001:2015 and ASTM E2016-11. These tests include mesh count verification, wire diameter measurement, aperture size accuracy, material composition analysis, and tensile strength tests. For specialized applications, additional tests like salt spray corrosion resistance or high-temperature stability might be performed. The service life of square wire mesh can extend for decades, particularly when made from high-grade stainless steel and properly maintained, offering significant long-term value in critical infrastructure.

Technical Parameters and Specifications of Square Wire Mesh

Understanding the technical specifications of square wire mesh is paramount for selecting the right product for specific industrial needs. Key parameters include mesh count (number of openings per linear inch), wire diameter, aperture size (opening size), material type, and weave pattern. These parameters directly influence the mesh's filtration efficiency, strength, and flow rate characteristics. For example, a finer mesh count with smaller apertures is ideal for precision filtration in chemical or pharmaceutical industries, while a coarser mesh with thicker wires is suited for heavy-duty screening in mining or aggregate processing. The table below outlines typical specifications for various common types of square wire mesh, providing a quick reference for technical decision-makers.

Diverse Applications Across Industries: Where Square Wire Mesh Excels

The versatility of square wire mesh makes it indispensable across a vast array of industries. In the petrochemical sector, it is vital for catalyst support, particulate filtration, and as protective screening in reactors and distillation columns, where its anti-corrosion properties are paramount. For the metallurgy industry, it serves as crucial sieving media for powders, granules, and as reinforcing material in high-temperature applications. Water treatment and drainage systems heavily rely on square wire mesh for pre-filtration, sediment removal, and general straining due to its high flow capacity and resistance to clogging.

Beyond these, its applications extend into agriculture for pest control and animal enclosures, construction for reinforcing concrete and plaster, and the food processing industry for sieving and drying. The mesh's uniform openings ensure consistent product quality in sieving applications, contributing to energy efficiency by optimizing material flow. Its robust structure provides reliable support and protection in various demanding environments, highlighting its economic advantages in terms of longevity and reduced maintenance. Many square wire mesh manufacturers provide specialized variants tailored for specific industry demands.

Key Advantages and Performance Benefits of Premium Square Wire Mesh

Investing in premium square wire mesh from reputable square wire mesh suppliers offers significant technical and economic advantages. Firstly, its uniform aperture size ensures highly efficient and precise separation or filtration, crucial for maintaining product purity and optimizing industrial processes. Secondly, the inherent strength and rigidity, especially in welded variants, provide superior load-bearing capabilities and structural integrity, essential for demanding industrial environments. Materials like stainless steel contribute excellent corrosion and oxidation resistance, significantly extending the mesh's operational lifespan in harsh chemical or high-temperature settings, thus reducing replacement costs and downtime.

Furthermore, the ease of cleaning and minimal maintenance requirements of square wire mesh translate into lower operational expenses and improved hygiene, particularly important in food and pharmaceutical applications. Its adaptable nature allows for diverse fabrication, including rolling, cutting, and forming, enabling seamless integration into various machinery and systems. These combined attributes underscore why square wire mesh remains a preferred choice for engineers and procurement specialists seeking reliable and cost-effective screening and support solutions.

Custom Solutions and Quality Assurance: Partnering with Leading Square Wire Mesh Exporters

As leading square wire mesh exporters and square wire mesh manufacturers, we understand that standard products may not always meet the precise demands of specialized industrial projects. Our commitment extends to providing comprehensive custom square wire mesh solutions, working closely with clients to tailor specifications such as mesh size, wire gauge, material composition, and panel dimensions. This bespoke approach ensures optimal performance and seamless integration into existing systems, minimizing modification costs and maximizing operational efficiency. We utilize advanced CAD/CAM technologies to design and simulate customized mesh structures, ensuring precision before manufacturing begins.

Our manufacturing processes adhere to strict quality management systems, including ISO 9001 certification, and our products undergo rigorous testing protocols in accordance with international standards. We provide material test reports (MTRs) and certificates of conformity for every batch, offering complete transparency and traceability. Our long-standing partnerships with global enterprises, spanning over two decades, are a testament to our consistent product quality and reliable service. We pride ourselves on being a trusted square wire mesh factory that prioritizes client satisfaction through superior product delivery and responsive support.

Why Choose Us: Expertise and Trustworthiness as Your Square Wire Mesh Supplier

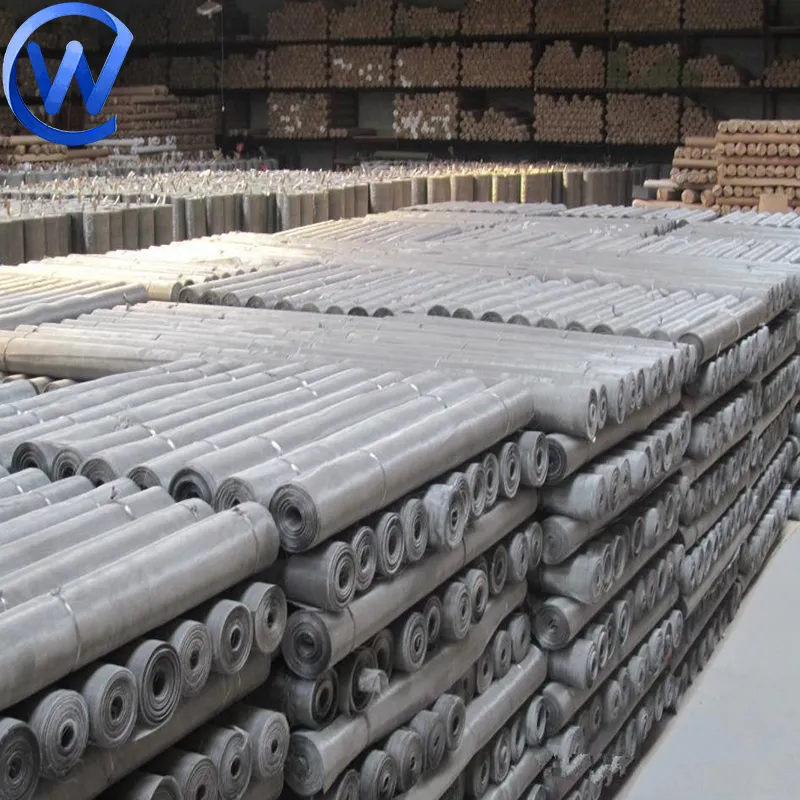

As a leading square wire mesh supplier, our commitment to excellence is reflected in our robust manufacturing capabilities and customer-centric approach. We possess state-of-the-art weaving and welding machinery, enabling us to produce a vast range of square wire mesh products, from ultrafine filtration meshes to heavy-duty industrial screens. Our team comprises seasoned engineers and technical experts with deep industry knowledge, providing unparalleled expertise in material selection, design optimization, and application support. We have successfully served diverse clients in over 50 countries, handling projects from small bespoke orders to large-scale wholesale square wire mesh consignments, demonstrating our global reach and logistical prowess.

Our reputation as a reliable square wire mesh factory is built on a foundation of quality, integrity, and consistent performance. We hold multiple industry accreditations and certifications, reinforcing our adherence to global quality benchmarks. Furthermore, our collaborative approach extends to continuous research and development, ensuring that our products not only meet but exceed evolving industry demands. We offer competitive pricing for wholesale square wire mesh without compromising on quality, making us the preferred partner for businesses seeking value and reliability.

Frequently Asked Questions (FAQ) about Square Wire Mesh

-

Q: What are the primary material options for square wire mesh?

A: The most common materials include stainless steel (304, 316, 316L), galvanized iron, low carbon steel, brass, and copper, chosen based on specific application requirements like corrosion resistance, strength, and conductivity.

-

Q: How do I determine the correct mesh count for my application?

A: The mesh count is determined by the size of particles you need to filter or screen. Finer particles require a higher mesh count (smaller apertures), while larger particles or structural applications may use a lower mesh count (larger apertures and thicker wires). Our technical team can assist with precise calculations.

-

Q: Is custom square wire mesh available?

A: Yes, we specialize in providing custom square wire mesh solutions. We can manufacture mesh to specific dimensions, wire diameters, aperture sizes, and even unique material compositions to meet your exact project requirements.

-

Q: What quality certifications do your products hold?

A: Our products adhere to international quality standards including ISO 9001:2015. We also conduct stringent internal quality checks and can provide material test reports and certificates of conformity upon request.

Delivery, Warranty, and Customer Support

We are committed to providing seamless service from order placement to final delivery. Our average delivery cycle for standard square wire mesh products typically ranges from 7-14 business days, depending on quantity and destination, while custom square wire mesh orders may require slightly longer lead times. We maintain robust logistics networks with trusted shipping partners to ensure timely and secure transit globally. For wholesale square wire mesh orders, dedicated account managers oversee the entire process to streamline operations and ensure efficiency.

All our high quality square wire mesh products come with a comprehensive quality assurance warranty, covering manufacturing defects and material integrity for a specified period. Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-sales support required. We believe in building long-term partnerships, providing consistent quality and reliable service that our clients can depend on.

References

- International Organization for Standardization (ISO) official publications on Quality Management Systems.

- ASTM International standards for wire mesh and sieves.

- Academic journals on materials science and engineering.

- Industry reports on global industrial mesh market analysis.

This is the last article

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025