-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ธ.ค. . 15, 2024 09:27 Back to list

fence wire mesh manufacturer

The Role of Fence Wire Mesh Manufacturers in Modern Construction

In the ever-evolving landscape of construction and landscaping, the demand for durable and efficient materials has led to the rising prominence of fence wire mesh manufacturers. These manufacturers play a crucial role in various applications, from agricultural fencing to industrial security and residential privacy, showcasing the versatility and necessity of wire mesh fencing in our everyday lives.

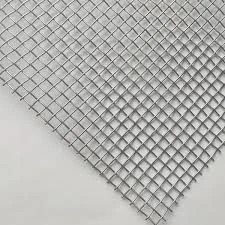

Understanding Fence Wire Mesh

Fence wire mesh is typically made from steel or wire materials that are woven or welded to create a grid-like pattern. This structure serves multiple purposes, including providing security, defining boundaries, and even enhancing aesthetic appeal. The manufacturing process involves multiple steps, including wire drawing, mesh fabrication, and surface treatment to ensure longevity and resistance to environmental elements.

Applications of Fence Wire Mesh

One of the key advantages of fence wire mesh is its versatility. It is used across various sectors including

1. Agriculture Farmers rely on wire mesh to protect crops and livestock from predators while simultaneously preventing animals from straying. Livestock fencing and garden fencing made from wire mesh are essential components in agricultural operations.

2. Industrial Security Industries often face the challenge of securing their premises against theft and vandalism. Wire mesh fencing provides a robust solution that allows visibility while maintaining a strong barrier against intruders. The use of heavy-duty wire mesh in industrial settings ensures both security and durability.

3. Residential Applications Homeowners seek wire mesh fencing for its affordability and effectiveness in keeping pets and children safe within their property. Additionally, decorative wire mesh fencing can enhance outdoor aesthetics while maintaining functional boundaries.

fence wire mesh manufacturer

The Manufacturing Process

Fence wire mesh manufacturers utilize advanced technology to ensure the production of high-quality mesh products. The manufacturing process typically involves the following steps

1. Wire Drawing Steel wires are drawn through a series of dies to achieve the desired thickness. This step is critical, as the strength of the wire significantly affects the durability of the finished product.

2. Mesh Fabrication The drawn wires are either woven or welded together to create sheets of wire mesh. Different patterns, such as square, rectangular, or diamond shapes, can be produced based on the intended application.

3. Surface Treatment To enhance resistance to corrosion and environmental wear, manufacturers apply various treatments, including galvanization or powder coating. These treatments increase the lifespan of the fence and reduce maintenance costs for end users.

4. Quality Control Finally, thorough quality checks are performed to ensure that the products meet industry standards. This includes testing for tensile strength, corrosion resistance, and dimensional accuracy.

Choosing the Right Manufacturer

When selecting a fence wire mesh manufacturer, several factors should be considered. Prospective buyers should look for manufacturers that offer a variety of products tailored to specific needs, provide detailed specifications, and implement robust quality assurance protocols. Additionally, customer reviews and testimonials can provide valuable insights into the manufacturer's reputation and reliability.

Conclusion

In conclusion, fence wire mesh manufacturers are integral to various sectors, providing essential products that enhance security, safety, and aesthetics in both rural and urban environments. The combination of advanced manufacturing techniques and innovation positions these manufacturers as key players in meeting the growing demands of the construction and landscaping industries. As we continue to seek out durable and effective solutions for fencing, the importance of quality wire mesh products will undoubtedly remain a top priority in the development of secure and functional spaces.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025