-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ก.ค. . 29, 2025 10:00 Back to list

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

This definitive guide dives deep into trend analysis, manufacturing processes, technical parameters, customization, and real-life case studies – all framed for engineers, infrastructure planners, and industry decision-makers.

Industry Overview & Trends in Hexagonal Gabion Applications (2024)

Global demand for Hexagonal Gabion solutions is accelerating—driven by stricter infrastructure safety standards and the push for resilient, eco-friendly construction. According to MarketsandMarkets, the hexagonal gabion market is projected to reach $3.5 billion USD by the end of 2027, growing at a CAGR of 7.2%.

- Hydraulic Engineering: Emphasis on robust riverbank, channel, and shoreline reinforcement.

- Transport Infrastructure: Highway, railway, and bridge projects worldwide are increasingly specifying Hexagonal Gabion for retaining and noise barrier structures.

- Eco-Landscaping: Use in green spaces, vertical gardens, and urban flood mitigation is soaring.

- Longevity & Compliance: Global standards now demand ISO 9001-certified production and materials traceability.

Leading engineers and environmental consultants cite the Hexagonal Gabion as the “gold standard” for versatile, durable, and adaptive mesh structures in civil works.

Hexagonal Gabion Market Growth (2018-2027, $M USD)

Material Science & Standards: What Sets Hexagonal Gabion Apart?

- Core Material: Heavily galvanized steel wire (GalFan® or Class A/B Zn-Al alloy coating) – per ISO 10244.

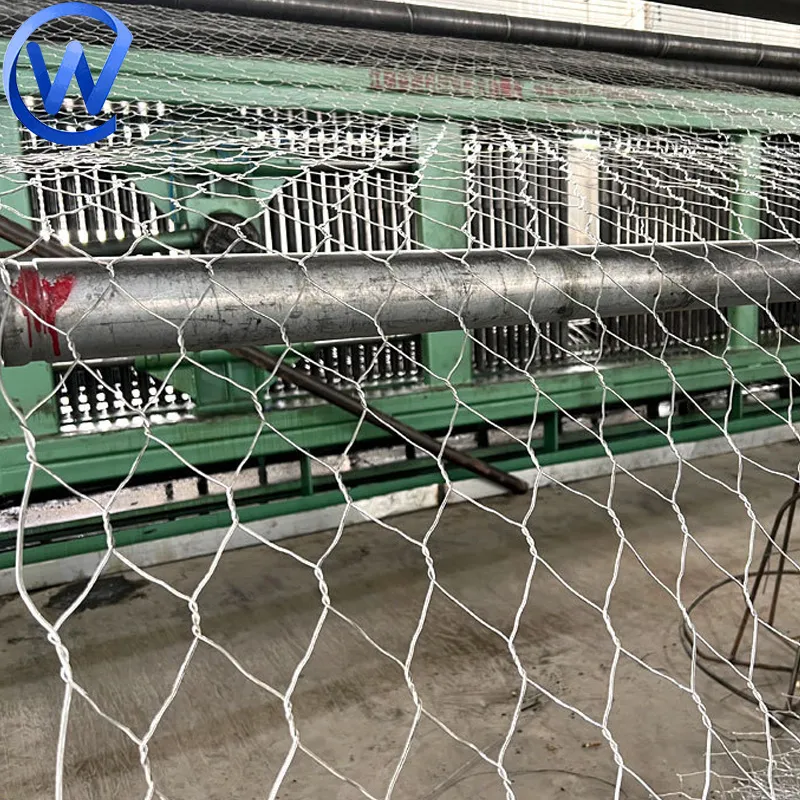

- Mesh Type: Hexagonal double-twisted, providing structural resilience and energy absorption under load (ASTM A975-20).

- Weaving Process: State-of-the-art CNC mesh weaving – uniform aperture, reduced risk of unraveling.

- Coating Options: Heavy zinc/Bright GalFan, or PVC/PE extruded for additional corrosion barrier (EN 10245 compliance).

- Testing Protocols: Every batch salt-spray tested (500-1000 hours), tensile strength ≥ 380-550 MPa (per ANSI/AWWA D6822).

| Parameter | Hexagonal Gabion | Industry Standard |

|---|---|---|

| Mesh Opening (mm) | 60 x 80 | 80 x 100 | 100 x 120 | 60 x 80 ~ 120 x 150 |

| Wire Diameter (mm) | 2.0 | 2.7 | 3.0 | 3.4 | 2.0 – 4.0 |

| Coating Mass (g/m²) | ≥ 245 (Zn) / ≥ 260 (Zn-Al) | ≥ 215 |

| Tensile Strength (MPa) | ≥ 380–550 | ≥ 350 |

| Service Life (outdoors, years) | ≥ 40–65 (Zn-Al/PVC) | ≥ 25 |

| Compliance | ISO, ASTM, EN | Variable |

Technical Parameter Evolution (Wire Tensile Strength vs. Service Life)

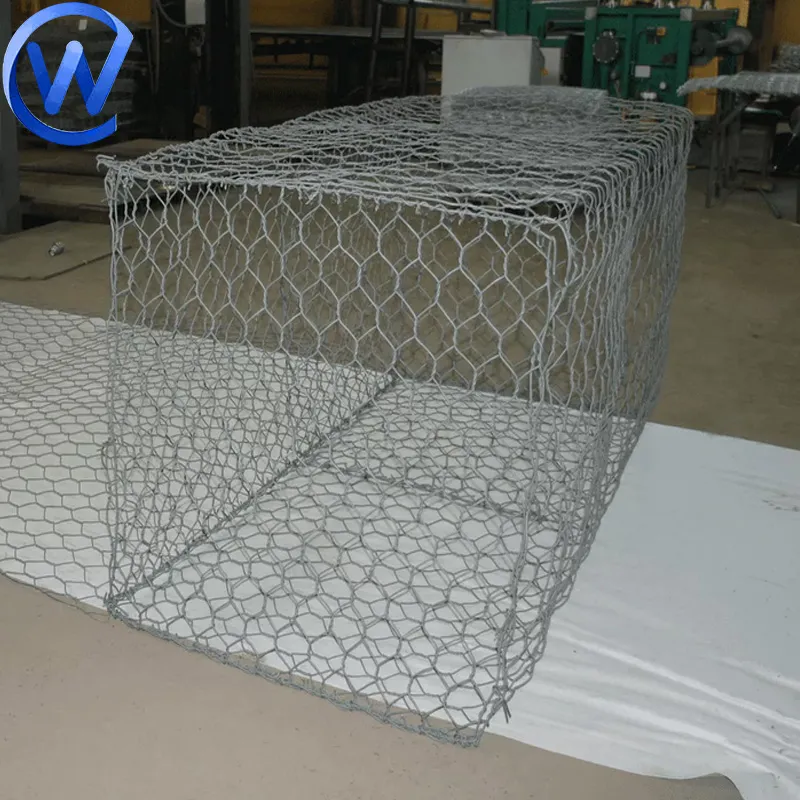

Manufacturing Process of Hexagonal Gabion

Modern Hexagonal Gabion Production Steps (ISO 9001 Workflow)

- Wire Selection & Inspection – Sourcing high-carbon, cold-drawn steel wire.

Key: Only ISO-9001 steel grades accepted. - Surface Galvanizing/GalFan® Coating – State-of-the-art molten dipping process, yielding 260-400g/m² coating for maximum anticorrosion.

EN ISO 1461, 10244 certified. - CNC Double-Twist Hexagonal Weaving – Automated mesh forming machines; tight aperture tolerance (±3mm).

- PVC/PE Extrusion (If Required) – Eco-friendly, UV-resistant polymer coating application (EN 10245 compliance).

- Panel Cutting & Selvedge Lacing – Edge wires and tie wire installed for optimal seam strength (meets ASTM A975-20).

- Dimensional Testing & Load Evaluation – Destructive and non-destructive load tests, mesh flatness, aperture checks.

- Packing, Documentation & Labeling – Batch certs, traceability codes, environmental compliance labeling.

Watch production video: Hexagonal Gabion Manufacturing Process (YouTube)

Key Advantages of Hexagonal Gabion vs. Traditional Retaining Systems

- Engineer-Tested Stability: Double-twisted hex mesh dissipates energy, resisting deformation under dynamic loads (critical for flood/landslide zones).

- Corrosion Resistance: GalFan/PVC/PE coatings provide 3–6x longer service life compared to plain galvanized wire baskets.

- Rapid, Modular Installation: Pre-assembled panels reduce labor costs by 25%+ (verified by project case studies in EU and Asia).

- Environmental Flexibility: Gabions adjust to ground settlement without losing retaining capacity; promote vegetation growth and habitat restoration.

- Cost Efficiency: Life-cycle cost 36% lower than cast-concrete walls in river, highway and mining projects, per ICE Proceedings, 2022.

| Feature | Hexagonal Gabion | Rectangular Gabion | Gravity Concrete Wall |

|---|---|---|---|

| Deformation absorbed | ✓ (Excellent) | Medium | Poor |

| Corrosion Resistance | ✓✓✓ (PVC/GalFan) | ✓ (Galvanized only) | n/a |

| ECO Compatibility | High | Medium | Low |

| Installation Time | Short (modular) | Medium | Very Long |

| Design Life (years) | 40–65 | 25–30 | 45–60 |

| Cost per m³ (USD) | 32–55 | 37–60 | 80–120 |

Material Cost Proportions in Gabion Production (2023, %)

Manufacturer Comparison: Global Hexagonal Gabion Leaders (2024)

| Brand/Company | Origin | ISO 9001 | Standard Wire | PVC/PE Coating | Industry Focus |

|---|---|---|---|---|---|

| GalvanizedMeshProducts | China | Yes | 2.0–4.0mm | ✓ | Civil, Hydraulic, Mining |

| Maccaferri | Italy | Yes | 2.0–3.0mm GalFan® | ✓ | Transport, River, Landscape |

| Tensar International | UK/USA | Yes | 2.7–3.4mm | ✓ | Geotechnics |

| Gabion Technologies | Germany | Yes | 2.7–3.0mm | ✓ | Urban, Transport |

| Ningbo Mesh | China | Yes | 2.7–3.4mm | ✓ | Export, Water Works |

Typical Applications of Hexagonal Gabion: Real-World Case Studies

Client: Provincial Water Resources Bureau

Description: Over 80 km of riverbank reinforced using Hexagonal Gabion baskets. Heavy GalFan & polymer coating.

Data: Design life certified >60 years; annual maintenance cost less than $1.8/m.

[Feedback]: “No structural failures even after record flooding; vegetation growth integrated rapidly.”

Client: Tollways Corp SE Asia

Specs: Gabion wall (height 4.2m) – soil anchor + mesh mix. Installed in 11 days (vs. 22-day standard).

[Result]: “Major cost savings, flawless structural integrity after two typhoon seasons.”

Sector: Oil & Gas

Need: Acid/alkali-resistant channel lining, EN 10245-certified PVC-coated mesh.

[Outcome]: “Corrosion resistance proven in post-install tests. No mesh degradation over 5-year period.”

Function: Vertical landscaping wall, supporting live planting substrate.

[Result]: “Gabion mesh enabled integrated irrigation and root development with zero mesh corrosion.”

Distribution of Hexagonal Gabion Application Sectors

Customization: Tailored Hexagonal Gabion Configurations

As a leading manufacturer, we offer full custom engineering for Hexagonal Gabion products:

- Mesh Opening: 60×80, 80×100, 100×120mm, or as required.

- Wire: Carbon, Zn-Al, stainless (AISI 304/316 for chemical resistance).

- Coatings: Galvanized, GalFan®, PVC, PE, polyester powder.

- Panel/Box Size: L × W × H up to 6.0 × 2.0 × 2.0m—custom shapes, partitions available.

- Color: Standard gray/green/black, or RAL color upon request.

- Accessories: Geotextile liner, diagonal bracing, lifting eyes, data plate marking.

- Bundled Logistics: Just-in-time global shipping, on-site field support.

FAQ: Professional Inquiries on Hexagonal Gabion

Q1: What is the optimum wire diameter for riverbank reinforcement applications?

A: For dynamic river zones, a wire diameter of 2.7–3.4mm (double-twisted, GalFan-coated) is recommended for highest tensile strength and corrosion resistance.

Q2: Which international standards should Hexagonal Gabion meet?

A: Leading projects require compliance with ISO 10244, ASTM A975, EN 10223-3, and ANSI/AWWA D6822 to guarantee mesh integrity and service life.

Q3: How is mesh opening size selected?

A: Common selections are 60×80mm for fine aggregate fill, 80×100mm for general slopes, and 100×120mm for large boulders or heavy-duty river works.

Q4: What is the typical installation standard for Hexagonal Gabions?

A: Install per ASTM D7012, ensure proper base preparation, tie wire lacing, and use diaphragms for boxes longer than 2m to prevent bulging.

Q5: What certification is provided with each batch?

A: Each delivery includes ISO/CE compliance certificate, mill test report, salt-spray test results, and batch traceability documentation.

Q6: How is corrosion performance validated?

A: Mesh undergoes accelerated salt-spray testing (per ASTM B117); target lifespan >1000 hours with no rust formation for premium Gabion grades.

Q7: How does gabion design affect hydraulic permeability?

A: The hexagonal mesh structure allows high permeability, dissipates water energy, and reduces hydrostatic pressure versus concrete walls, minimizing the risk of wall failure.

Delivery, Warranty & Support

- Delivery Lead-Time: 15–22 days standard production; urgent/stock for fast-track projects available.

- Warranty: 10-year product warranty (material, coating & workmanship defects).

- After-Sales Service: 24/7 technical support – site problem-solving, field repair guidance, and design optimization feedback.

- Certification & Documentation: All batches supplied with EN, ISO, CE compliance docs and product traceability codes.

- Trusted Clients: Verified supply for World Bank projects, major EPC contractors, national railway, and oil/gas majors.

Industry Certifications & References

- ISO 9001:2015 Quality Management System – audited compliance.

- EN 10244 / EN 10223 – galvanized/pvc mesh product standard.

- ASTM A975 / ASTM D7012 – US industry installation and performance benchmarks.

- CE marking for all export deliveries to EU, UKCA/ROHS for UK.

1. “Mechanical Properties and Service Life of Double-Twisted Hexagonal Gabions: Experimental Study,” J. of Constructional Steel Research, 2022. Source

2. International Gabion Forum, Gabion Retaining Wall Designs

3. “Cost/Benefit Analysis of Gabion vs. Concrete for Flood Control,” ICE Proceedings Engineering Sustainability, 2022. Source

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025